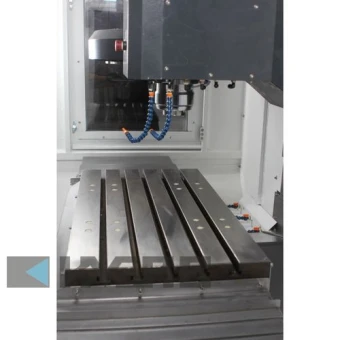

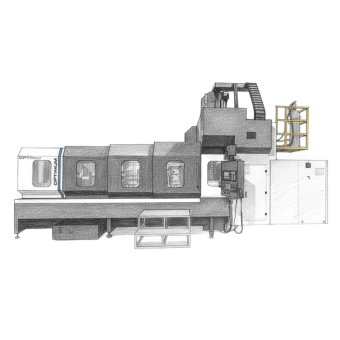

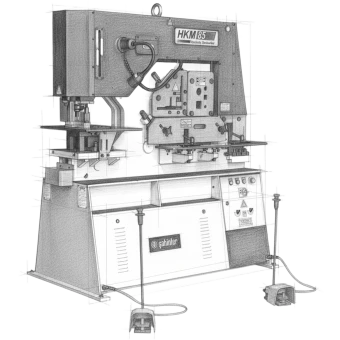

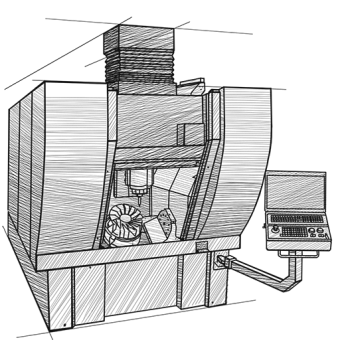

CNC milling machining center GMC3262bu

SKU 1920024

0 reviews

In stock

WEIDA

Shipping

- Pickup (Self-pickup) (For free)

- New POST (Up to 100 UAN)

- Meest (Up to 100 UAN)

Payment

- Payment upon receipt

- Cash payment

- Payment by bank details

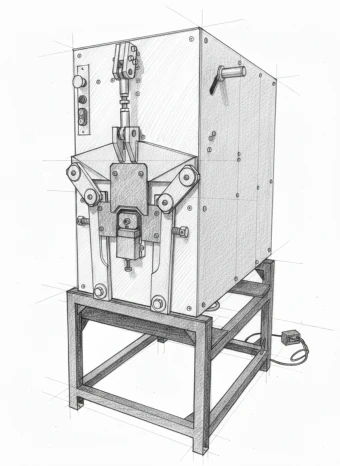

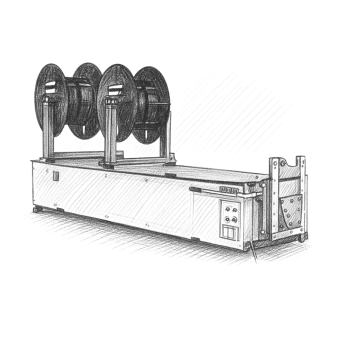

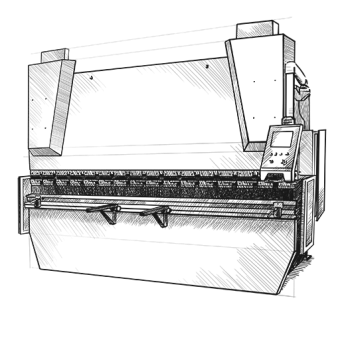

CNC milling machining center GMC3262bu is modern equipment with numerical control designed for complex metalworking. The bridge gantry construction and modular design ensure rigidity and precision when machining large parts.

GMC3262bu is suitable for milling, drilling, threading, and contour machining of complex components. The multi-axis system guarantees high precision, making this machining center ideal for producing large-scale parts with increased quality requirements.

The machining center is used in the following industries:

Aerospace industry

Automotive industry

Military industry

Mold and tooling production

Shipbuilding

Energy sector

Technical specifications GMC3262bu:

Distance from spindle to table: 250–1250 mm.

Spindle speed: 18000 rpm.

Tool type: HSK63A.

Maximum tool weight: 8 kg.

Table size: 6000×3000 mm.

Maximum table load capacity: 5000 kg/m².

Traverse speed along X/Y/Z axes: 15 m/min.

Power consumption: 150 kVA.

Advantages and features GMC3262bu:

The monolithic U-shaped frame ensures structural stability and rigidity.

Optical scales and closed-loop control minimize errors.

Circulating cooling of the spindle and screws maintains thermal stability.

The gantry construction saves up to 44% of space compared to classic models.

The chain conveyor for chip removal and automatic lubrication simplify maintenance.

You can purchase the CNC milling machining center GMC3262bu from the company KVERB.

We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the CNC milling machining center GMC3262bu.

GMC3262bu is suitable for milling, drilling, threading, and contour machining of complex components. The multi-axis system guarantees high precision, making this machining center ideal for producing large-scale parts with increased quality requirements.

The machining center is used in the following industries:

Aerospace industry

Automotive industry

Military industry

Mold and tooling production

Shipbuilding

Energy sector

Technical specifications GMC3262bu:

Distance from spindle to table: 250–1250 mm.

Spindle speed: 18000 rpm.

Tool type: HSK63A.

Maximum tool weight: 8 kg.

Table size: 6000×3000 mm.

Maximum table load capacity: 5000 kg/m².

Traverse speed along X/Y/Z axes: 15 m/min.

Power consumption: 150 kVA.

Advantages and features GMC3262bu:

The monolithic U-shaped frame ensures structural stability and rigidity.

Optical scales and closed-loop control minimize errors.

Circulating cooling of the spindle and screws maintains thermal stability.

The gantry construction saves up to 44% of space compared to classic models.

The chain conveyor for chip removal and automatic lubrication simplify maintenance.

You can purchase the CNC milling machining center GMC3262bu from the company KVERB.

We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the CNC milling machining center GMC3262bu.

Specifications CNC milling machining center GMC3262bu

- Table size 6000 × 3000 mm

- Spindle speed 18000 RPM

- Cutting feed rate (X/Y/Z) 1-6000/1-6000/1-12000 mm/min

- Max. Travel For X Axis 6200

- Max. Travel For Y Axis 3200

- Max. Travel For Z Axis 1250

- Spindle Nose To Table 250-1500 mm

- Max. Table Capacity 5000

- Spindle Motor Power 56/70 kW

- Number of axes 5

- WEIGHT 96000

- LENGTH 10200

- WIDTH 8600

- HEIGHT 6600

Reviews

There are no reviews on this product yet, be the first

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21