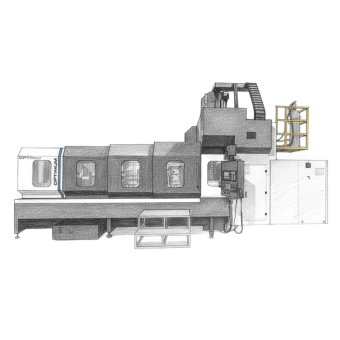

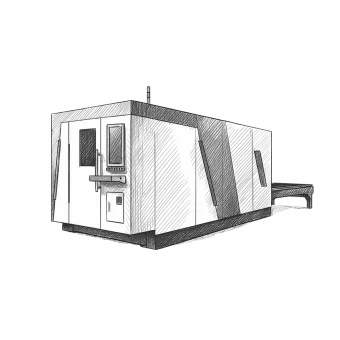

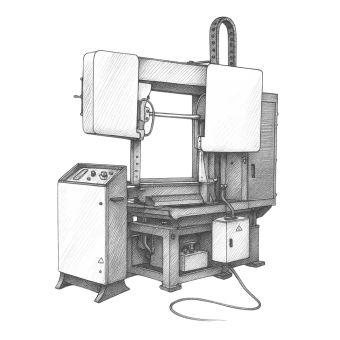

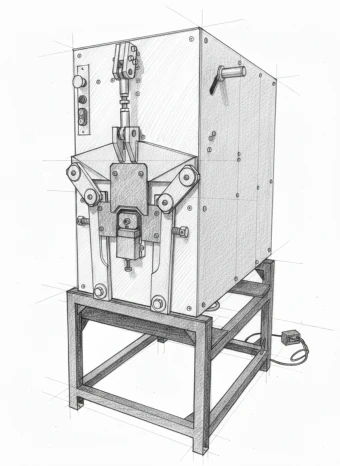

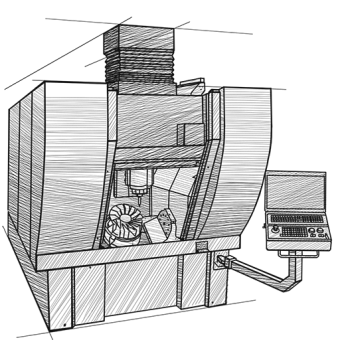

Vertical CNC milling machining center VMC966

SKU 1920031

0 reviews

In stock

WEIDA

Shipping

- Pickup (Self-pickup) (For free)

- New POST (Up to 100 UAN)

- Meest (Up to 100 UAN)

Payment

- Payment upon receipt

- Cash payment

- Payment by bank details

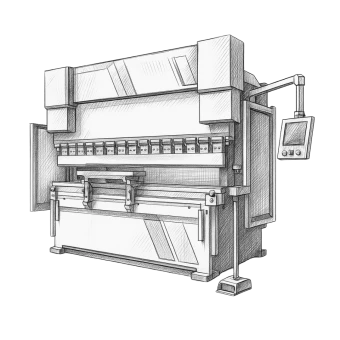

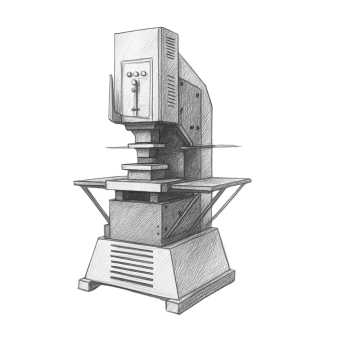

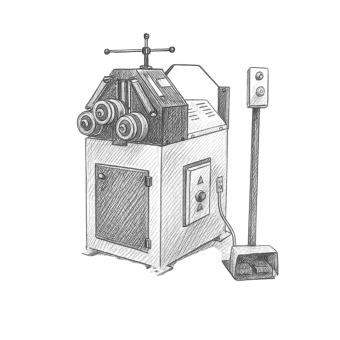

Vertical CNC milling machining center VMC966 is high-precision equipment designed for comprehensive mechanical machining of parts. The robust construction, advanced electronics, and high-quality components ensure stable operation under challenging conditions.

VMC966 is used for precise milling, drilling, threading, and other operations with various materials, including light alloys and hardened steel. The machine is ideally suited for serial production of parts in mechanical engineering, aerospace, automotive, and other industries.

The machining center VMC966 is an excellent solution for enterprises producing precision parts, molds, dies, and structural elements. Its wide range of settings makes it suitable for both small workshops and large factories.

Technical specifications VMC966:

Spindle speed: 40–8000 rpm.

Tool type: BT40.

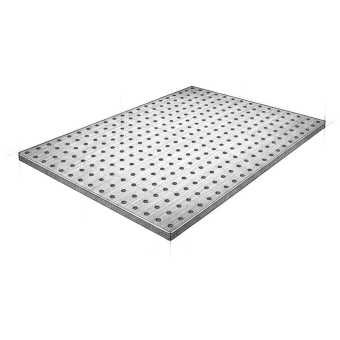

Table size: 1000×550 mm.

Maximum table load capacity: 500 kg.

Traverse speed along X/Y/Z axes: 48000 mm/min.

Power consumption: 11 kW.

Advantages and features VMC966:

German bearings and Taiwanese ball screws ensure reliability and long service life.

The synchronous spindle assembly guarantees high performance and operational stability.

Various configurations of control systems allow adapting the equipment to production needs.

Efficient cooling maintains a stable temperature during extended operation.

Quick tool changes reduce downtime and increase productivity.

You can purchase the Vertical CNC milling machining center VMC966 from the company KVERB.

We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the Vertical CNC milling machining center VMC966.

VMC966 is used for precise milling, drilling, threading, and other operations with various materials, including light alloys and hardened steel. The machine is ideally suited for serial production of parts in mechanical engineering, aerospace, automotive, and other industries.

The machining center VMC966 is an excellent solution for enterprises producing precision parts, molds, dies, and structural elements. Its wide range of settings makes it suitable for both small workshops and large factories.

Technical specifications VMC966:

Spindle speed: 40–8000 rpm.

Tool type: BT40.

Table size: 1000×550 mm.

Maximum table load capacity: 500 kg.

Traverse speed along X/Y/Z axes: 48000 mm/min.

Power consumption: 11 kW.

Advantages and features VMC966:

German bearings and Taiwanese ball screws ensure reliability and long service life.

The synchronous spindle assembly guarantees high performance and operational stability.

Various configurations of control systems allow adapting the equipment to production needs.

Efficient cooling maintains a stable temperature during extended operation.

Quick tool changes reduce downtime and increase productivity.

You can purchase the Vertical CNC milling machining center VMC966 from the company KVERB.

We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the Vertical CNC milling machining center VMC966.

Specifications Vertical CNC milling machining center VMC966

- Table size 1000 × 550 mm

- Spindle speed 40-8000 RPM

- Cutting feed rate (X/Y/Z) 1-10000 mm/min

- Max. Tool Diameter(Full/Empty) 78/120 мм

- Max. Tool Length 300

- Max. Tool Weight 8

- Max. Travel For X Axis 900

- Max. Travel For Y Axis 600

- Max. Travel For Z Axis 600

- Spindle Nose To Table 100-700 mm

- Max. Table Capacity 500

- Spindle Motor Power 11 kW

- Number of axes 3

- WEIGHT 5500

- LENGTH 2600

- WIDTH 2280

- HEIGHT 2800

Reviews

There are no reviews on this product yet, be the first

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21