Steel production is not just about melting metal — it is a complex chain of raw materials that directly affect the efficiency, sustainability, and cost-effectiveness of the process.

According to the World Steel Association, the key raw materials include iron ore, coking coal, limestone, and scrap metal.

This article explores:

1. which materials are used;

2. how much of each is needed to produce steel;

3. the main challenges — environmental, logistical, and resource-based;

4. their significance for metallurgy and metalworking.

1. Main Raw Materials and Their Quantities

Iron Ore

• On average, producing 1,000 kg of crude steel through the integrated route (BF/BOF — blast furnace + converter) requires about 1,370 kg of iron ore.

• Iron ore is mined in about 50 countries; the largest producers are Australia, Brazil, India, China, the United States, and Russia.

• Global reserves are estimated at over 800 billion tonnes of ore, containing more than 230 billion tonnes of iron.

Coking Coal and Coke

• Coking coal is a key input in blast furnace steelmaking: coke acts as both a reducing agent for iron ore and a source of heat.

• Approximately 1 billion tonnes of metallurgical coal are used each year in steelmaking — about 15% of total global coal consumption.

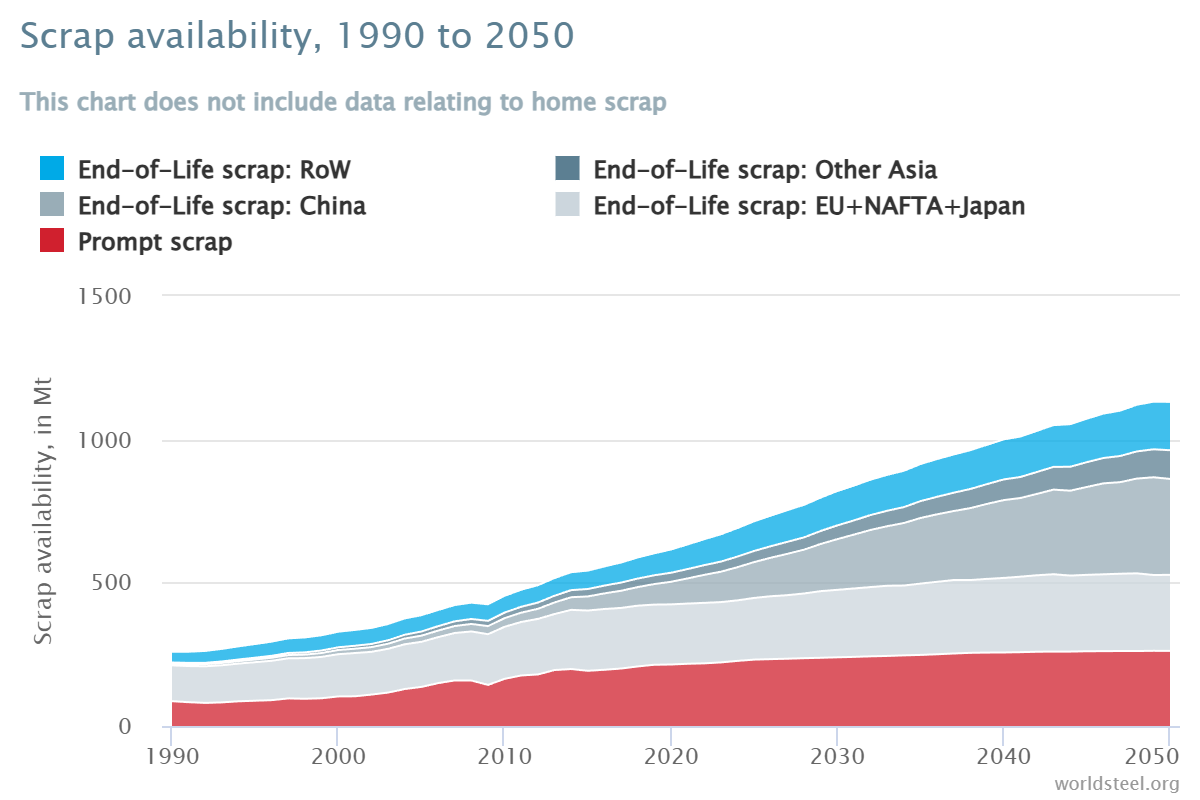

Scrap Metal

• Scrap is not waste but a valuable secondary raw material. Steel is highly recyclable due to its magnetic properties.

• In electric arc furnace (EAF) steelmaking, scrap can account for up to 100% of the raw mix; in traditional BF/BOF routes — up to 30%.

• Each tonne of scrap used prevents ≈1.5 tonnes of CO₂ emissions and saves 1.4 tonnes of iron ore, 740 kg of coal, and 120 kg of limestone.

2. Steelmaking Routes

The World Steel Association identifies two main steel production routes:

• BF/BOF (integrated) — blast furnace + converter; uses large quantities of iron ore, coal, limestone, and scrap.

• EAF (electric arc furnace) — primarily based on scrap, direct reduced iron (DRI), or “hot metal,” powered by electricity.

Typical material input: 710 kg of scrap, 586 kg of iron ore, 150 kg of coal, and 88 kg of limestone per 1,000 kg of steel.

Increasing the share of EAF production is one of the key global trends in the steel industry.

3. Key Challenges

Shortage of Quality Scrap

• Despite its potential, high-quality scrap is in short supply — many countries already face collection deficits.

• Impurities such as copper, tin, or nickel affect steel quality, requiring additional cleaning or DRI blending.

Dependence on Raw Materials and Logistics

• Mining of iron ore and coking coal is concentrated in a few countries, creating geopolitical and logistical risks.

• Heavy reliance on major importers necessitates diversified supply chains and adaptable production technologies.

Environmental and Energy Challenges

• Traditional BF/BOF routes have a high carbon footprint and face stricter environmental regulations (such as CBAM in the EU).

• Transitioning to EAF technologies requires major investment, equipment upgrades, and innovation in energy management.

4. Importance for Metallurgy and Metalworking

• Understanding the composition of raw inputs (iron ore, scrap, coal) helps manufacturers optimize budgets, logistics, and sustainability reports.

• For metalworking enterprises — builders of structures, frames, or heavy machinery — steel quality and supplier material base directly affect the strength and durability of finished products.

• Scrap recycling and efficient material use are becoming competitive advantages: lower costs, reduced emissions, and stronger corporate reputation.

Raw materials are the foundation of steelmaking. Increasing recycled content, reducing dependence on mining, and improving input quality are crucial goals for the industry’s sustainable future.

Source:

World Steel Association — “Raw materials – Introduction, Iron ore, Coal and coke, Scrap, Steelmaking materials markets” (worldsteel.org)

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21