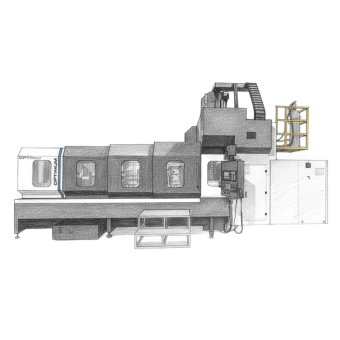

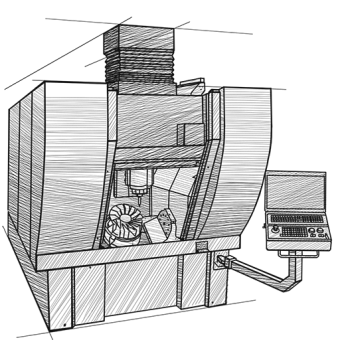

Vertical CNC milling machining center Equiptop 600APC

SKU 1920003

0 reviews

In stock

EQUIPTOP

Shipping

- Pickup (Self-pickup) (For free)

- New POST (Up to 100 UAN)

- Meest (Up to 100 UAN)

Payment

- Payment upon receipt

- Cash payment

- Payment by bank details

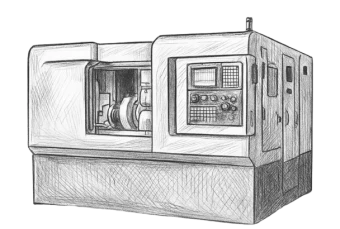

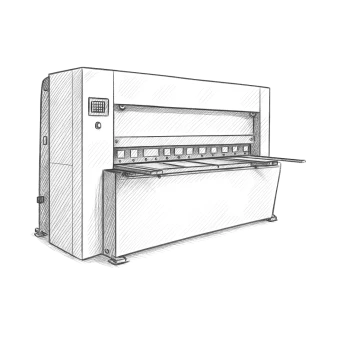

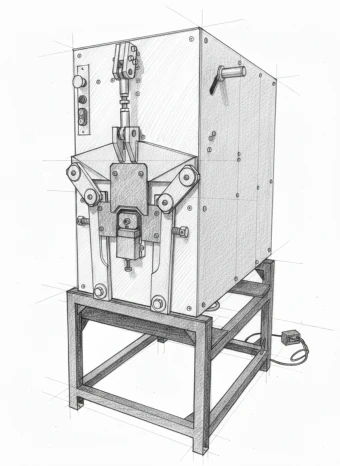

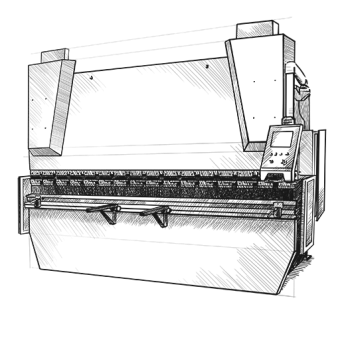

Vertical CNC milling machining center Equiptop 600APC is designed for high-precision processing of metal and other materials. Equipped with advanced technologies, it ensures stability, reliability, and high productivity in performing various operations.

Equiptop 600APC is used for milling, drilling, threading, and other types of mechanical processing. The machine guarantees consistent quality and precision of parts even in serial production.

This milling center is suitable for enterprises in mechanical engineering, aviation, automotive, and other industries. The machine is used for manufacturing complex geometry parts, components made of stainless steel, aluminum, and other materials.

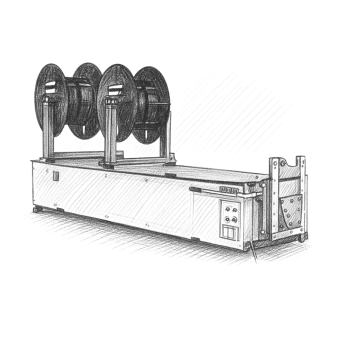

Technical specifications of Equiptop 600APC:

Distance from spindle to table: 150–630 mm

Spindle speed: 10000 rpm (optional 11000/12000/15000)

Tool type: sleeve-less 16T

Maximum tool diameter: 120 mm

Maximum tool weight: 6 kg

Tool shank type: BT40

Motor: 1.5/1.5 kW

Table size: 720x460 mm

Maximum table load capacity: 550 kg

Travel speed along X/Y/Z axes: 36 m/min (linear guides)

Working feed rate: 1–10000 mm/min

Controller: M70/M80 or Oi-MF

Power consumption: 20 KVA

Air consumption: 6 kg/cm²

Advantages and features of Equiptop 600APC:

The laser travel compensation system ensures maximum processing precision.

The floating spindle tension mechanism extends the bearing service life.

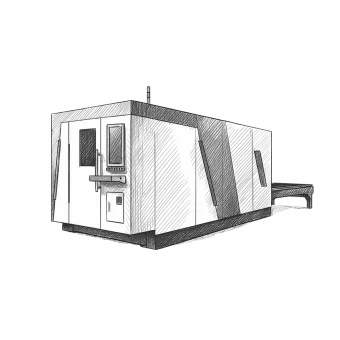

The enclosed protective cover guarantees operator safety.

Convenient access to the tool stand and coolant reservoir simplifies maintenance.

High-precision linear guides increase the rigidity and wear resistance of the structure.

You can purchase the Vertical CNC milling machining center Equiptop 600APC from the company KVERB.

We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the Vertical CNC milling machining center Equiptop 600APC.

Equiptop 600APC is used for milling, drilling, threading, and other types of mechanical processing. The machine guarantees consistent quality and precision of parts even in serial production.

This milling center is suitable for enterprises in mechanical engineering, aviation, automotive, and other industries. The machine is used for manufacturing complex geometry parts, components made of stainless steel, aluminum, and other materials.

Technical specifications of Equiptop 600APC:

Distance from spindle to table: 150–630 mm

Spindle speed: 10000 rpm (optional 11000/12000/15000)

Tool type: sleeve-less 16T

Maximum tool diameter: 120 mm

Maximum tool weight: 6 kg

Tool shank type: BT40

Motor: 1.5/1.5 kW

Table size: 720x460 mm

Maximum table load capacity: 550 kg

Travel speed along X/Y/Z axes: 36 m/min (linear guides)

Working feed rate: 1–10000 mm/min

Controller: M70/M80 or Oi-MF

Power consumption: 20 KVA

Air consumption: 6 kg/cm²

Advantages and features of Equiptop 600APC:

The laser travel compensation system ensures maximum processing precision.

The floating spindle tension mechanism extends the bearing service life.

The enclosed protective cover guarantees operator safety.

Convenient access to the tool stand and coolant reservoir simplifies maintenance.

High-precision linear guides increase the rigidity and wear resistance of the structure.

You can purchase the Vertical CNC milling machining center Equiptop 600APC from the company KVERB.

We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the Vertical CNC milling machining center Equiptop 600APC.

Specifications Vertical CNC milling machining center Equiptop 600APC

- Table size (720 × 400) × 2 mm

- Spindle speed 8000 RPM

- Cutting feed rate 1-10000 mm/min

- Max. Tool Diameter 120

- Max. Tool Length 300

- Max. Tool Weight 6

- Max. Travel For X Axis 600

- Max. Travel For Y Axis 460

- Max. Travel For Z Axis 480

- Spindle Nose To Table 150-630 mm

- Max. Table Capacity 550x2 kg

- Spindle Motor Power (Mitsubishi/Fanuc) 7.5/7.5 kW

- Number of axes 3

- WEIGHT 5000

Reviews

There are no reviews on this product yet, be the first

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21