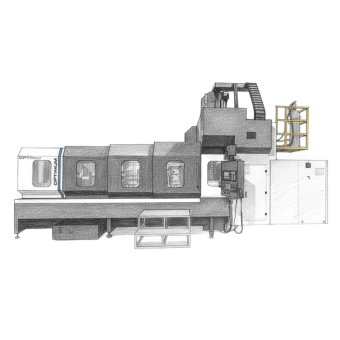

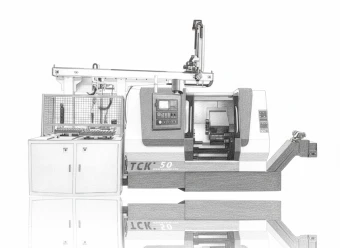

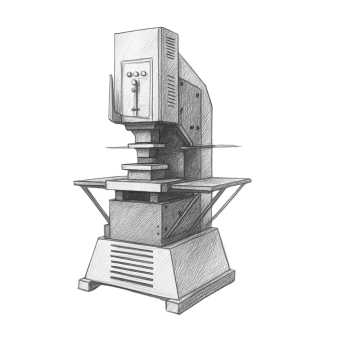

Lock forming machine Schlebach SPM-LM-QA60

SKU 8855-222-10

0 reviews

In stock

SCHLEBACH

Shipping

- Pickup (Self-pickup) (For free)

- New POST (Up to 100 UAN)

- Meest (Up to 100 UAN)

Payment

- Payment upon receipt

- Cash payment

- Payment by bank details

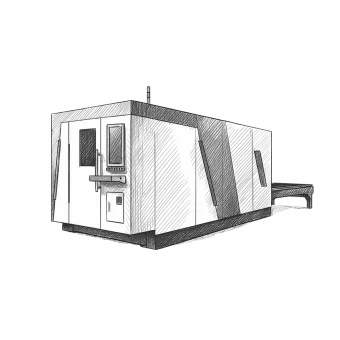

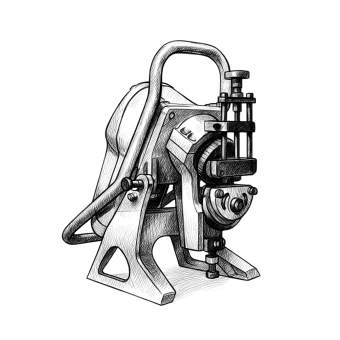

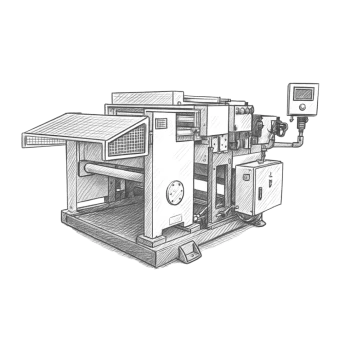

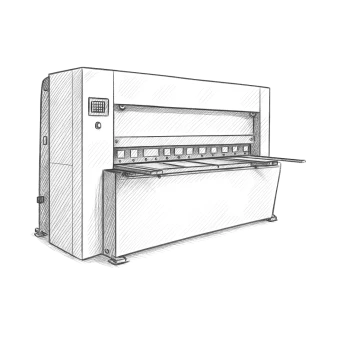

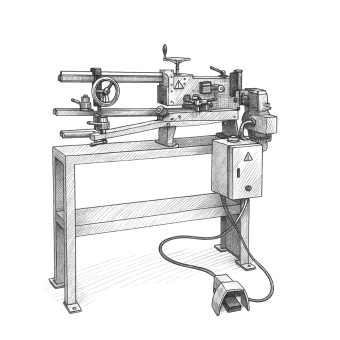

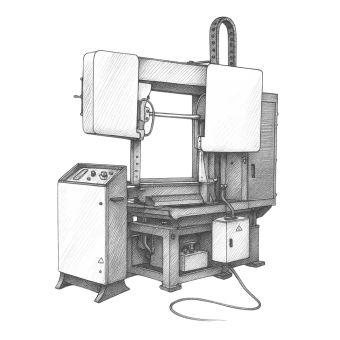

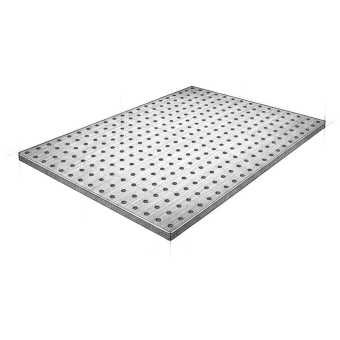

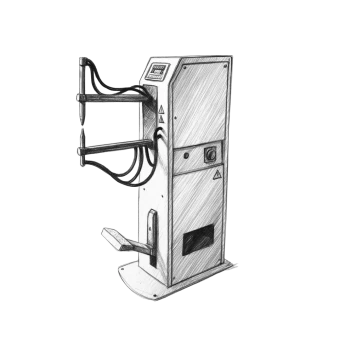

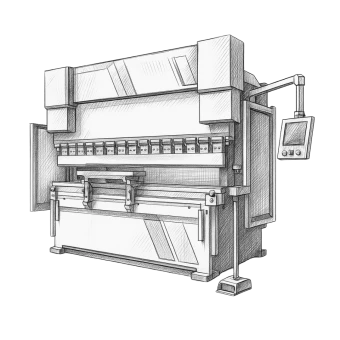

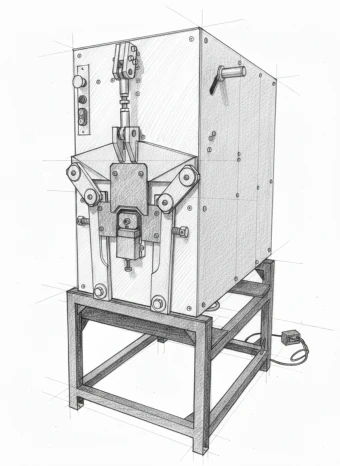

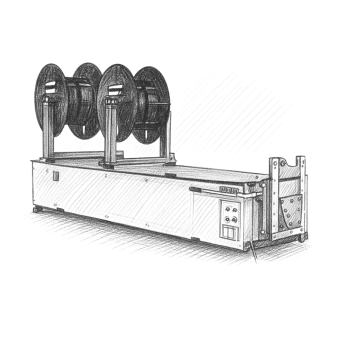

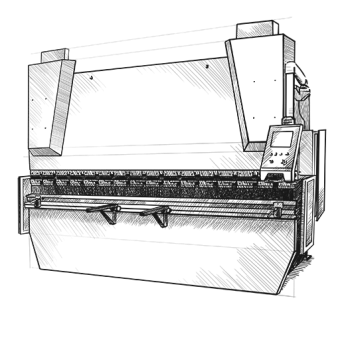

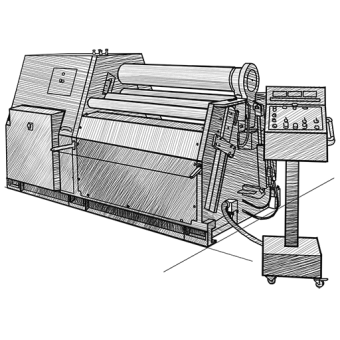

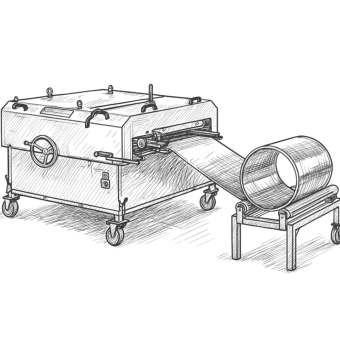

Lock forming machine Schlebach SPM-LM-QA60 is a multifunctional model for forming a double standing seam with a height of 25 or 32 mm, with the possibility of cutting panels after roll forming. The equipment can be used in the standard version or with a clip lock, and the modular design allows additional units to be installed as needed.

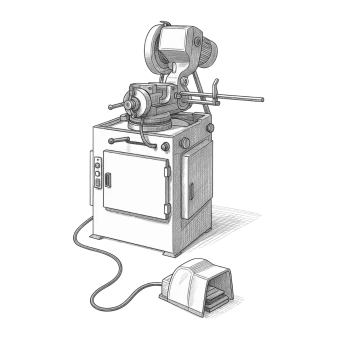

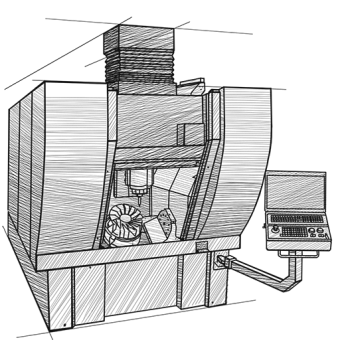

The model is equipped with a QA60 system with a manual circular saw that performs cross cutting after profiling at an angle up to 60° in both directions. It is also possible to install an RS roller cutter for cutting before roll forming, as well as the RS+LS configuration for longitudinal and cross cutting. Thanks to cutting after forming, it is possible to use blanks with a length from 100 mm. Control is carried out via a touch panel with a special control system.

Schlebach SPM-LM-QA60 is suitable for:

Companies producing panels of various lengths and geometry

Installation teams fitting panels on site

Manufacturers requiring automation and high cutting accuracy

Enterprises working with non-ferrous metals and custom solutions

Technical specifications:

Drive power: 1.1 kW

Feed width: 260–870 mm (up to 1080 mm)

Feed height: 890 mm

Axial dimension: 190–800 mm (up to 1010 mm)

Operating speed: up to 11 m/min

Forming stages: 7

Minimum panel length: 100 mm

Length tolerance: ±1–2 mm

Weight: 560 kg

Advantages and features:

QA60 circular system for cutting after profiling

Cutting angle up to 60° in both directions

Option to install RS and LS cutters

Touch control with a special interface

Feed system with braking mechanism

Profile rollers made of steel with anti-corrosion protection

Ball bearing guides

Elastic mounts of upper rollers

You can buy the lock forming machine Schlebach SPM-LM-QA60 from KVERB company:

We offer:

Delivery throughout Ukraine

Official warranty and technical support

Consultations for configuration selection for your tasks

Contact our managers and get a favorable offer for Schlebach SPM-LM-QA60.

The model is equipped with a QA60 system with a manual circular saw that performs cross cutting after profiling at an angle up to 60° in both directions. It is also possible to install an RS roller cutter for cutting before roll forming, as well as the RS+LS configuration for longitudinal and cross cutting. Thanks to cutting after forming, it is possible to use blanks with a length from 100 mm. Control is carried out via a touch panel with a special control system.

Schlebach SPM-LM-QA60 is suitable for:

Companies producing panels of various lengths and geometry

Installation teams fitting panels on site

Manufacturers requiring automation and high cutting accuracy

Enterprises working with non-ferrous metals and custom solutions

Technical specifications:

Drive power: 1.1 kW

Feed width: 260–870 mm (up to 1080 mm)

Feed height: 890 mm

Axial dimension: 190–800 mm (up to 1010 mm)

Operating speed: up to 11 m/min

Forming stages: 7

Minimum panel length: 100 mm

Length tolerance: ±1–2 mm

Weight: 560 kg

Advantages and features:

QA60 circular system for cutting after profiling

Cutting angle up to 60° in both directions

Option to install RS and LS cutters

Touch control with a special interface

Feed system with braking mechanism

Profile rollers made of steel with anti-corrosion protection

Ball bearing guides

Elastic mounts of upper rollers

You can buy the lock forming machine Schlebach SPM-LM-QA60 from KVERB company:

We offer:

Delivery throughout Ukraine

Official warranty and technical support

Consultations for configuration selection for your tasks

Contact our managers and get a favorable offer for Schlebach SPM-LM-QA60.

Specifications Lock forming machine Schlebach SPM-LM-QA60

- Supply voltage 400 V / 50 Hz / 3 Ph.

- Drive power 1.1 kW

- Operating speed max. 11 m/min

- Forming stages 7 stations

- Infeed width 260 – 870

- Axial dimension 190 – 800

- Infeed height 890

- Processable materials <ul> <li>Titanium zinc up to 0.8 mm</li> <li>Copper up to 0.8 mm</li> <li>Aluminium up to 0.8 mm</li> <li>Sheet steel (galvanized and coated) up to 0.7 mm</li> <li>Stainless steel up to 0.5 mm</li> </ul>

- Length tolerance approx. 1 – 2 mm

- WEIGHT 560 kg

- LENGTH 3 000 mm

- WIDTH 2 200 mm

- HEIGHT 1 100 mm

Reviews

There are no reviews on this product yet, be the first

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21