CNC PLATE ROLLING MACHINES

Filters

Filters

PRODUCTS YOU HAVE VIEWED

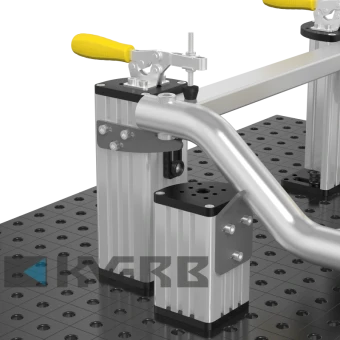

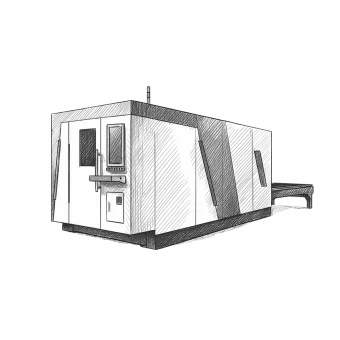

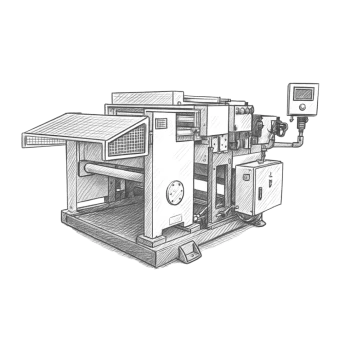

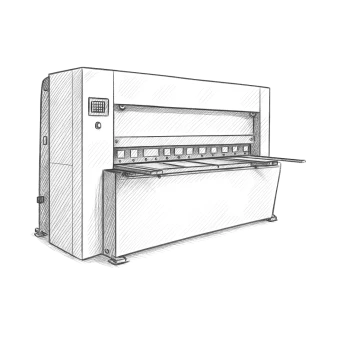

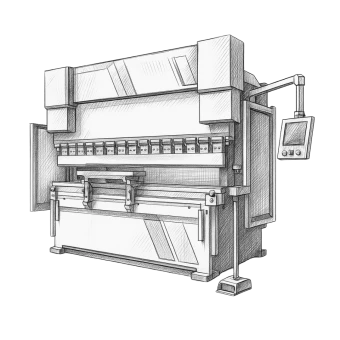

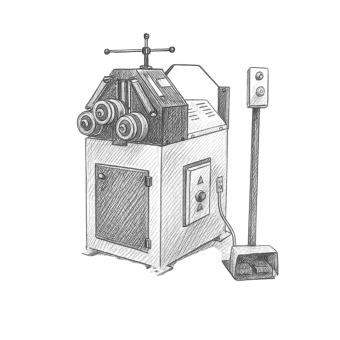

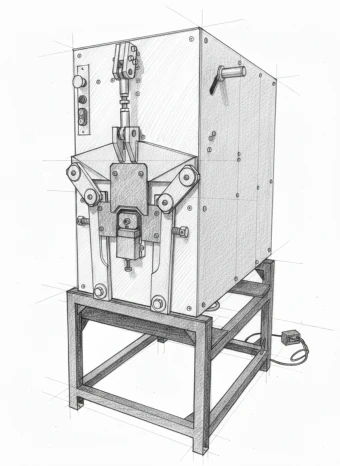

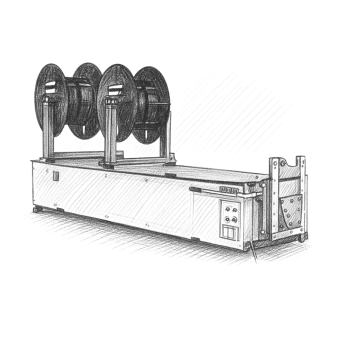

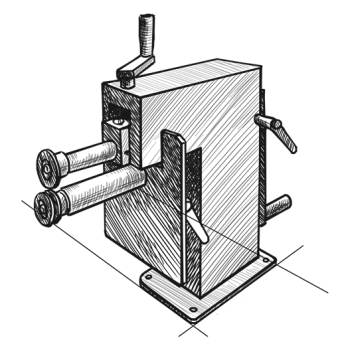

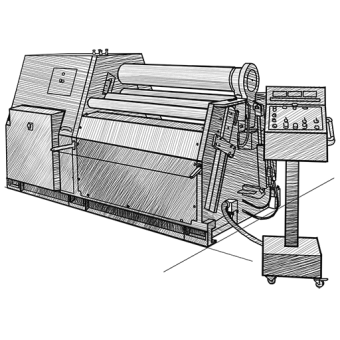

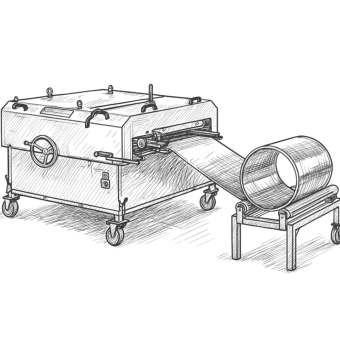

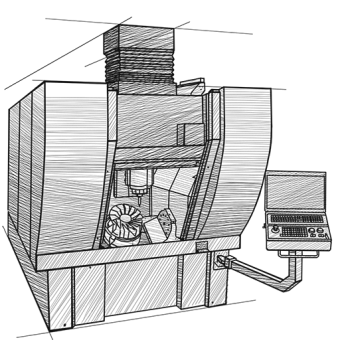

CNC plate rolls are modern industrial equipment for sheet metal bending, equipped with computer numerical control. These machines automatically control the movement of the rolls, which ensures maximum precision, repeatability of operations, and the ability to perform complex tasks without operator involvement. CNC plate rolls for sheet metal are used in the production of cylinders, conical parts, tanks, and other products where perfect shape and high bending quality are important.

CNC systems allow you to predefine bending parameters: diameter, thickness, length, feed speed, and pressing force. Thanks to this, the equipment is ideal for serial production as well as custom orders requiring high precision.

Advantages of automated control

Using CNC plate rolls provides many advantages:

Maximum bending accuracy and minimal deviation from specified parameters.

Full process automation: from program loading to finished product.

Reduced dependence on the human factor and operator skill level.

High speed and production efficiency.

Ability to store and reuse programs.

Minimized waste and defects.

Such plate rolls are in demand at enterprises engaged in the production of metal structures, ventilation systems, tanks, pipes, housings, and other products requiring stable quality and high performance.

How to choose CNC plate rolls?

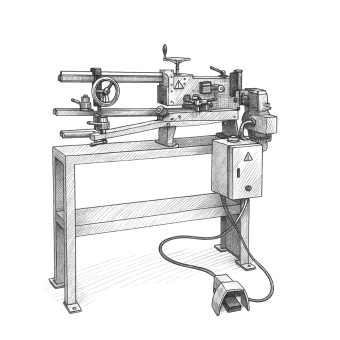

When choosing CNC plate rolls, it is important to consider:

The maximum thickness and width of the processed sheet.

The number of working rolls (3 or 4).

Type of design (asymmetrical, symmetrical).

Power of the electric drive and hydraulic parameters (if any).

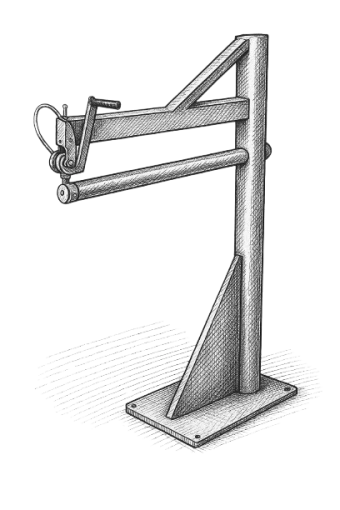

Support for conical bending function.

Availability and functionality of the CNC system.

Brand, reviews, availability of service and spare parts.

For industrial enterprises with high production volumes, it is recommended to buy CNC plate rolls from trusted manufacturers offering training, warranty service, and spare parts supply.

Where to buy CNC plate rolls?

KVERB company offers a wide selection of CNC models at affordable prices.

Catalog with detailed technical specifications and descriptions.

Wholesale and retail sales.

Professional consultations and assistance with selection.

Delivery throughout Ukraine.

Official warranty and service support.

CNC plate roll manufacturers presented at KVERB

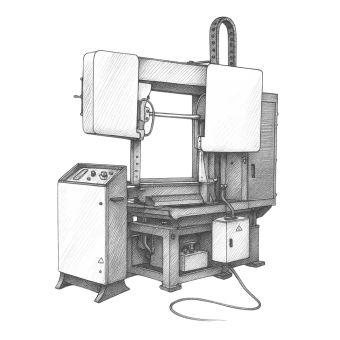

LIMA (Croatia)

Reliable industrial-grade 3-roll and 4-roll CNC plate rolls, ideally suited for serial production. They feature a strong structure, precise bending, and extended control functionality.

Popular models: LIMA SL-3-W 3000/4000/5000/6000 CNC, LIMA SL-3 3000/4000/5000/6000 CNC.

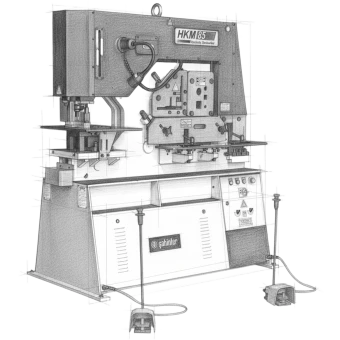

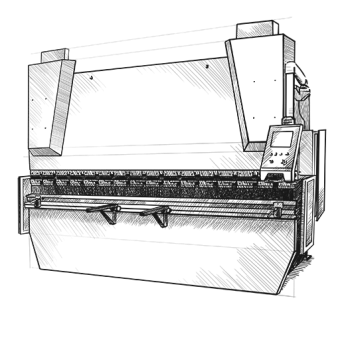

Sahinler (Turkey)

A world-leading manufacturer of plate rolling machines. Produces CNC equipment for heavy industry, mechanical engineering, and metal construction production.

CNC models: 4R HC, 4R HSS, 4RH, 3R UHS.

Isitan (Turkey)

Reliable and high-precision CNC and hydraulic drive machines. Models are suitable for bending both thin and thick sheets. They support automation, parameter settings, and series production.

Models: Isitan 4R HMS, 3R HMD, MRM-H, with CNC support.

Prinzing (Germany)

A European leader in the production of automated plate rolls.

Popular automatic machines: Prinzing RBA, RBB, RBAZ, RZK.

Buying CNC plate rolls at KVERB means investing in quality, precision, and production stability.

Submit a request — and receive a personalized offer!

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21