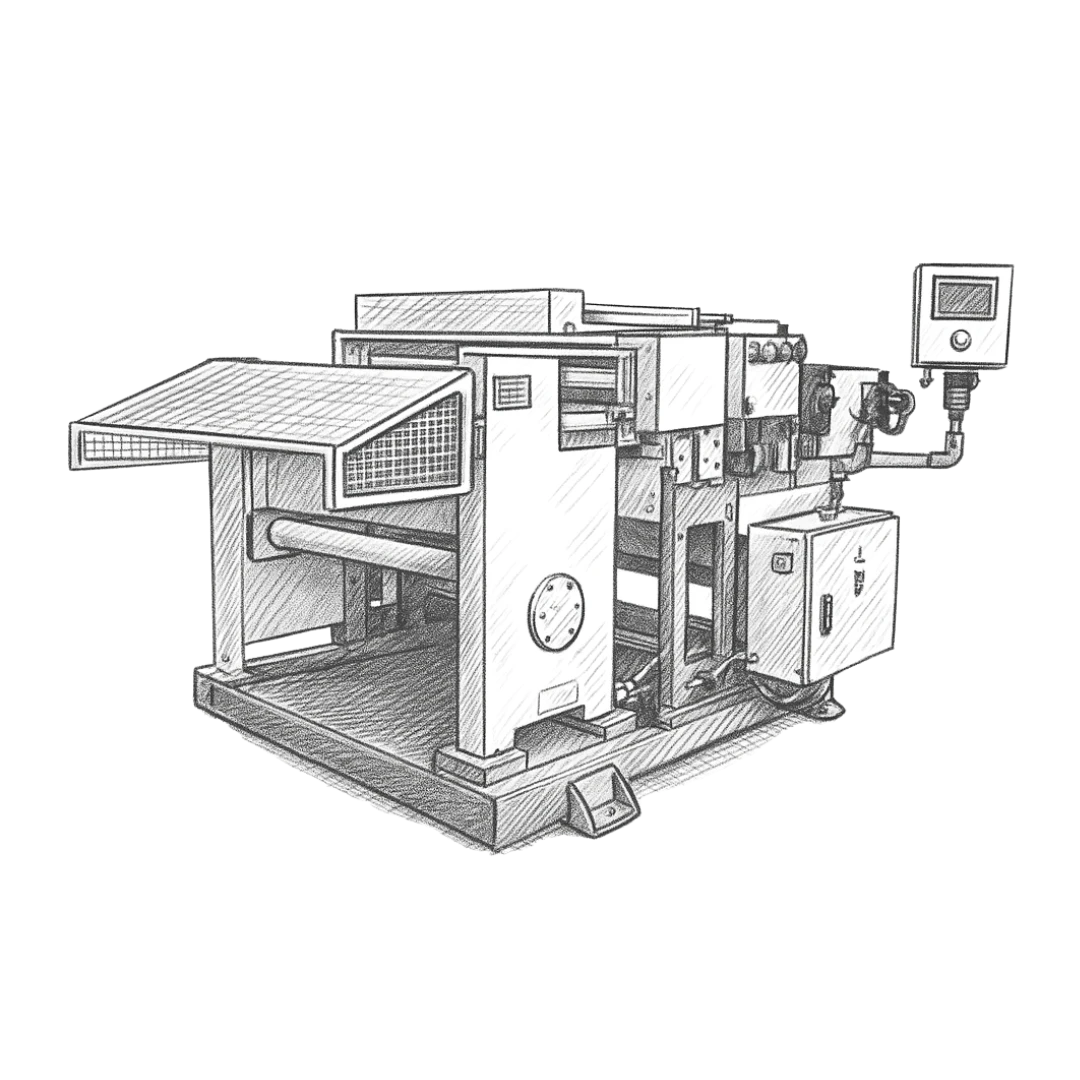

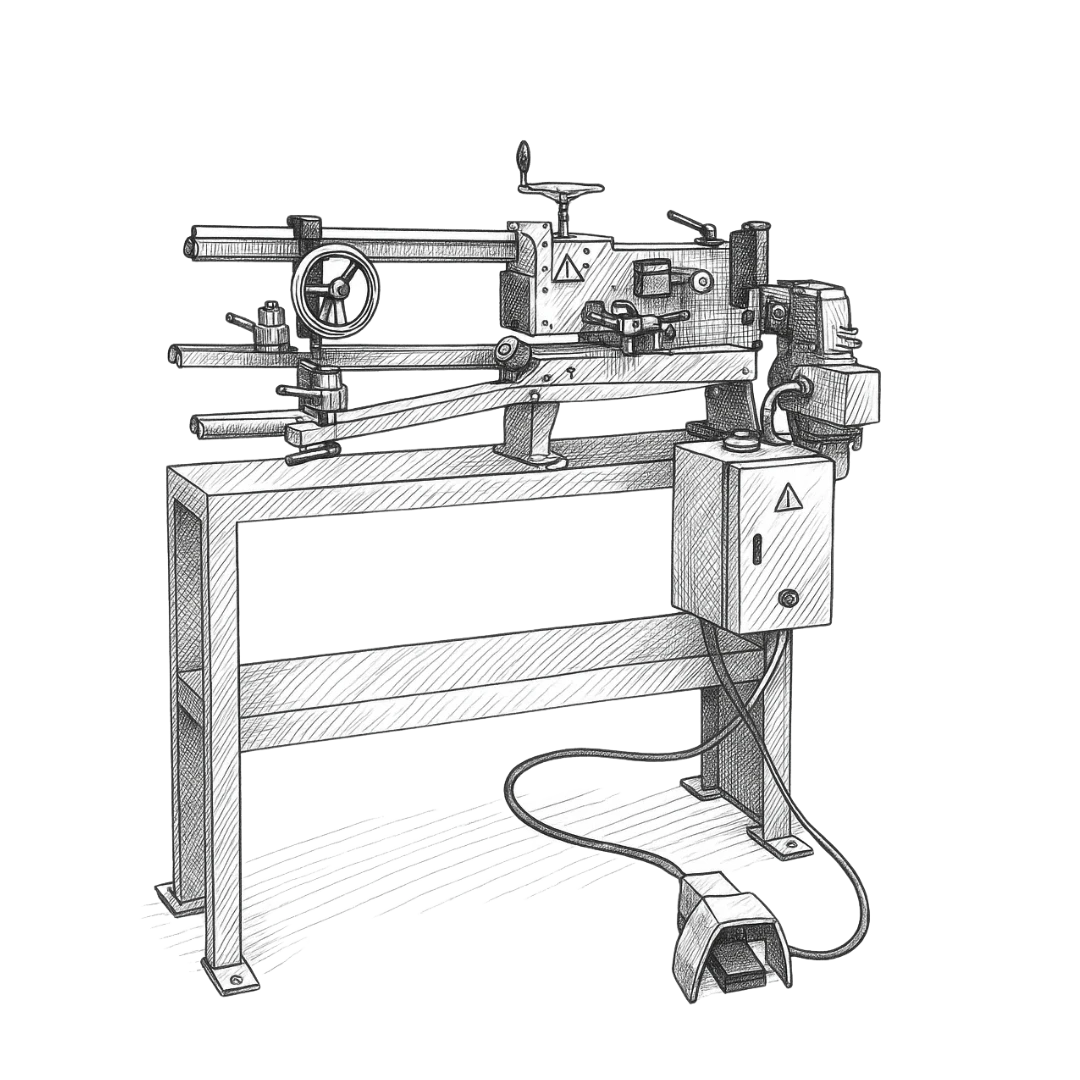

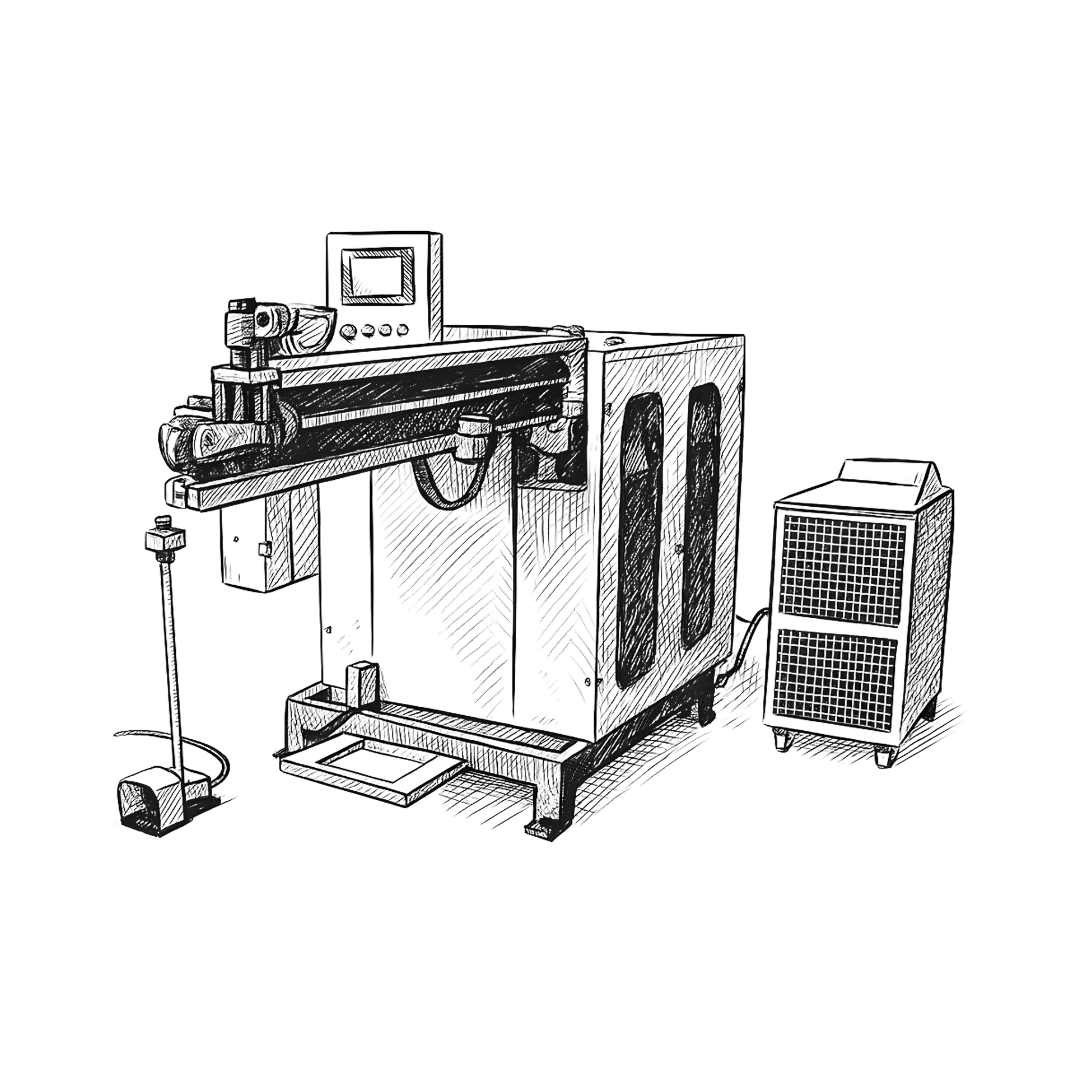

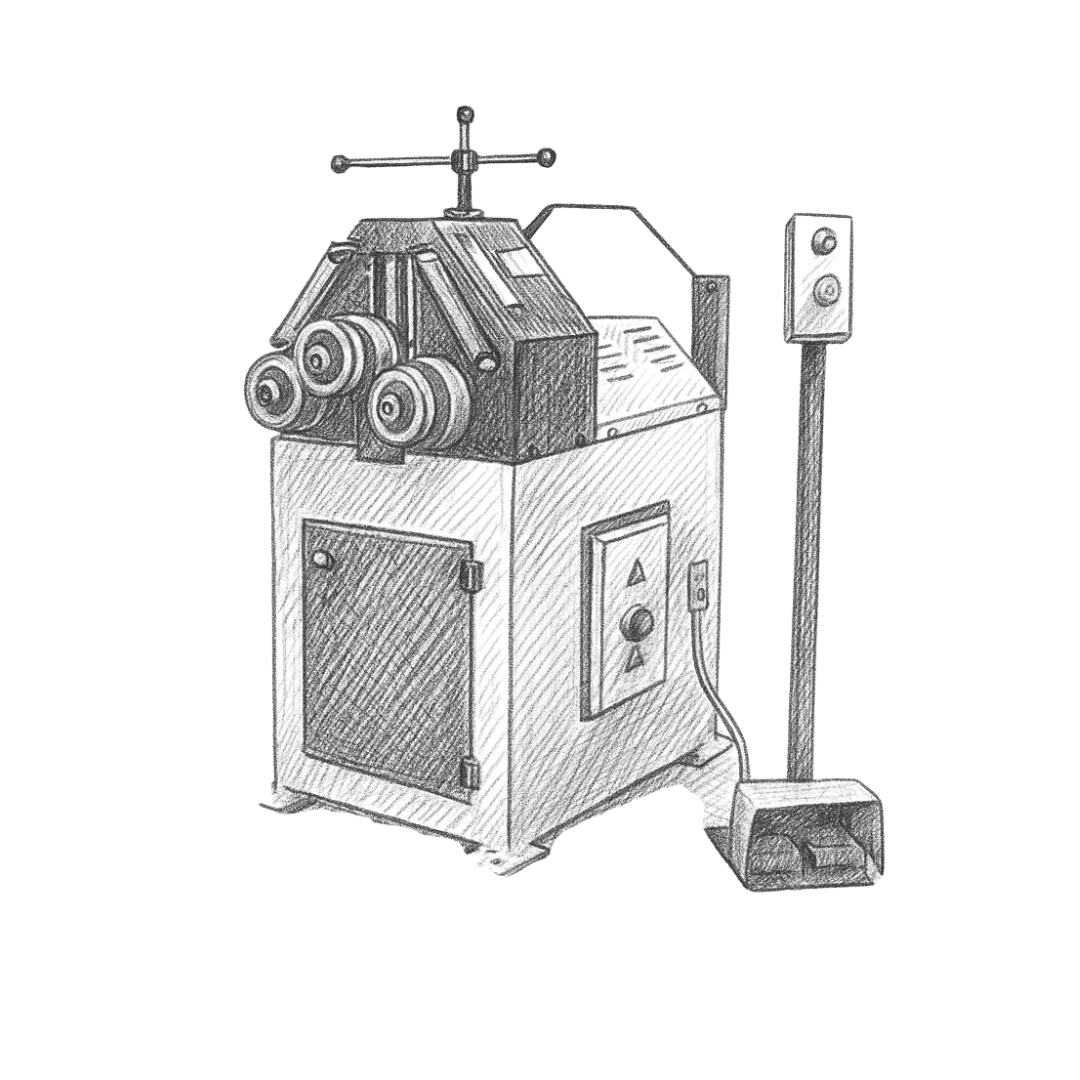

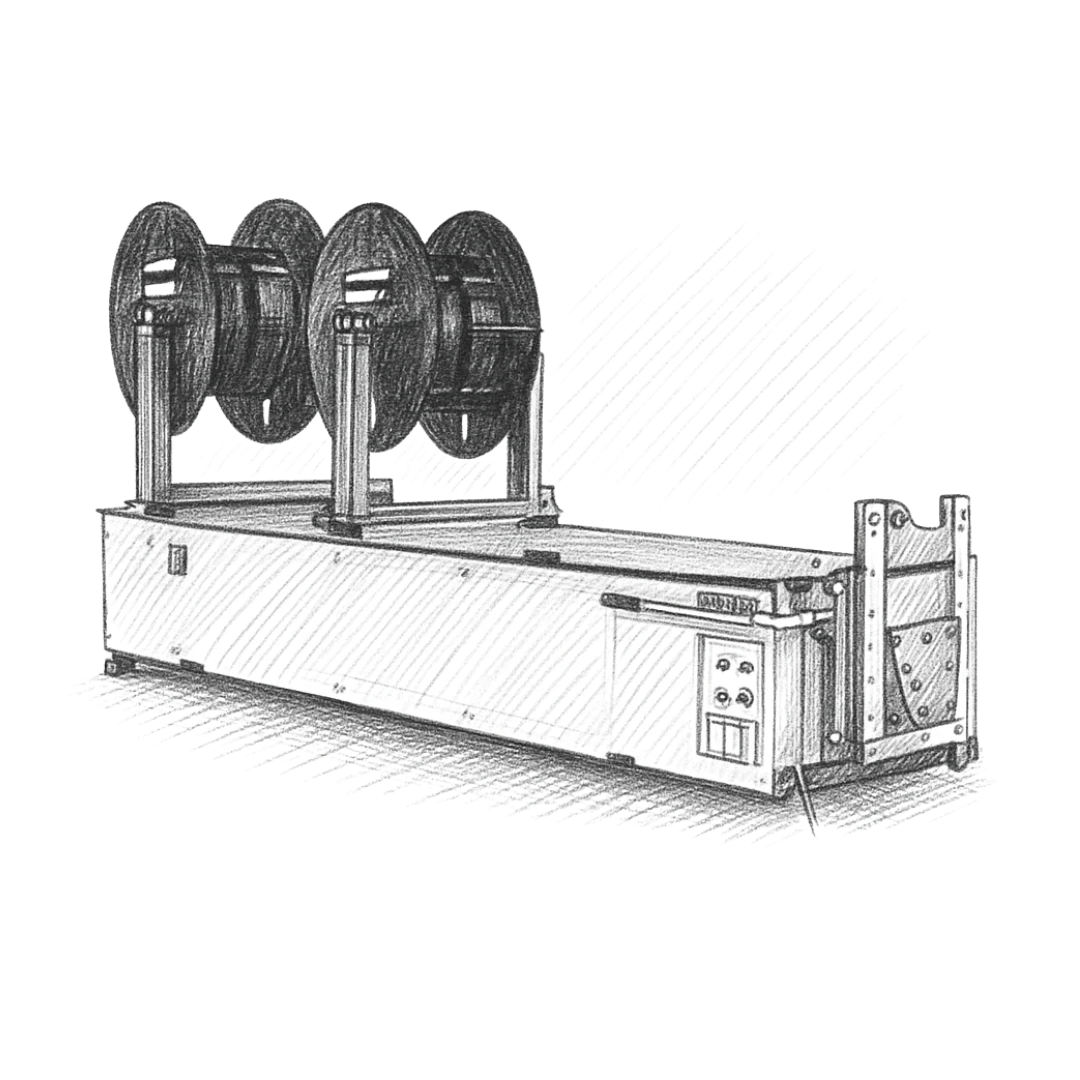

Metal rolling machine Sahinler 4R HS-L 12-130

SKU 9092-001-170

0 reviews

In stock

SAHINLER

0 uah.

Shipping

- Pickup (Self-pickup) (For free)

- New POST (Up to 100 UAN)

- Meest (Up to 100 UAN)

Payment

- Payment upon receipt

- Cash payment

- Payment by bank details

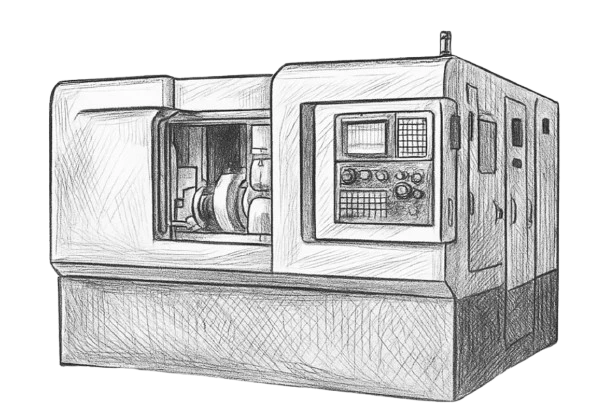

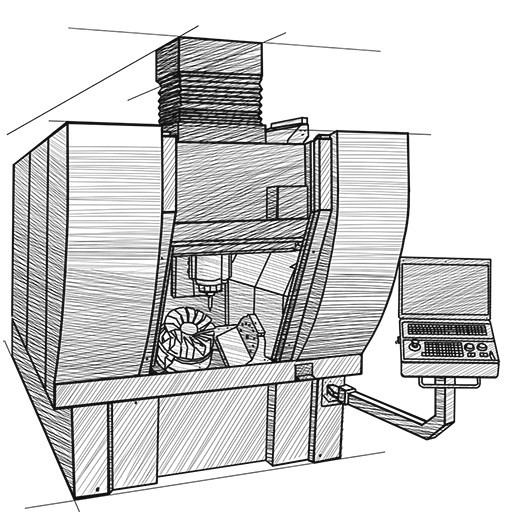

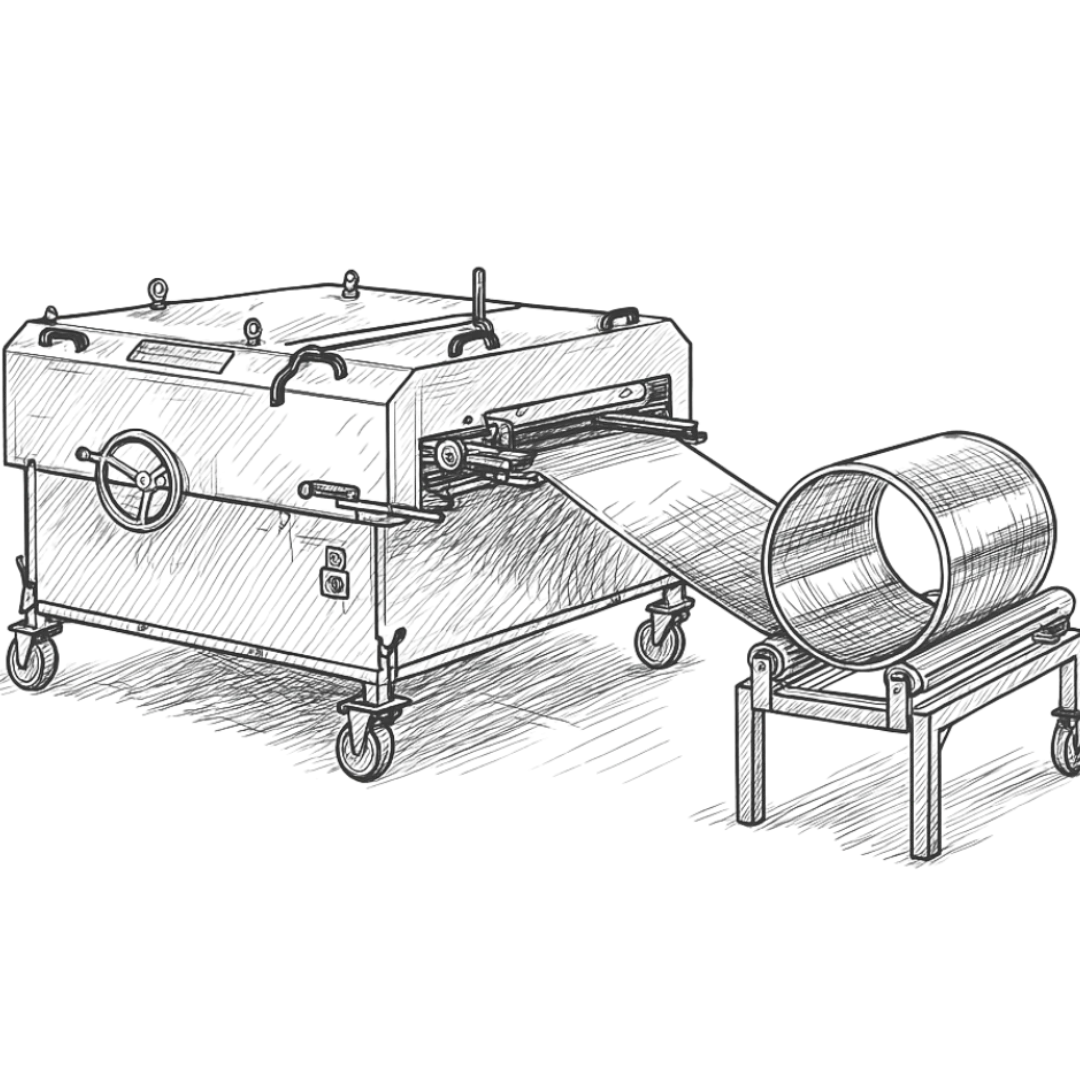

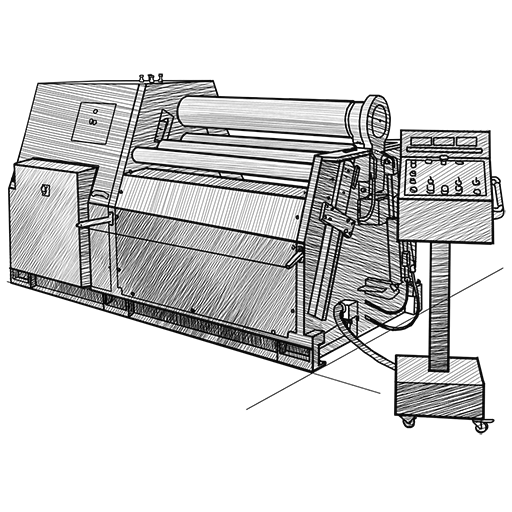

Rolling machine Sahinler 4R HS-L 12-130 is an industrial machine designed for precise bending of sheet metal. Its sturdy construction and modern technologies ensure reliable operation for performing complex production tasks.

The model is used for shaping metal blanks into cylindrical, conical, and other shapes. It is applied in the production of pipes, tanks, ventilation ducts, metal structures, and other products.

Sahinler 4R HS-L 12-130 is suitable for enterprises in mechanical engineering, shipbuilding, construction, and metalworking. It ensures high precision when working with various types of metals and is ideal for both mass and custom production.

Technical specifications of rolling machine Sahinler 4R HS-L 12-130

Useful bending length 1270 mm

Maximum sheet thickness for pre-bending 5 mm

Maximum sheet thickness for rolling 4 mm

Maximum stainless steel thickness for rolling 3 mm

Upper roller diameter 130 mm

Side roller diameter 130 mm

Motor power 3 kW

Working speed 1.5–6 m/min

Dimensions (LxWxH) 3350x1100x1150 mm

Weight 2350 kg

Advantages and features of rolling machine Sahinler 4R HS-L 12-130

Increased power allows processing thick metal with high precision

Optimized control system – the option to install NC or CNC for automation

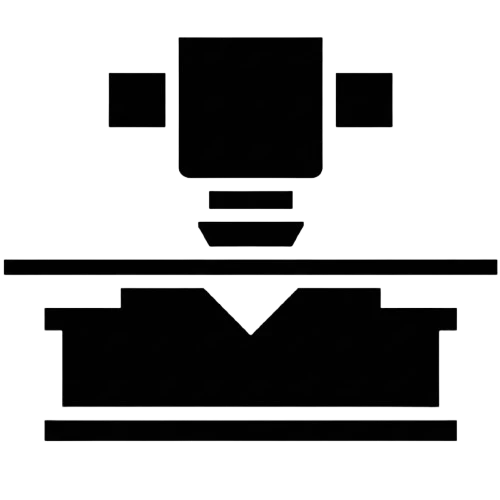

Four-roll design – ensures even pressure and high-quality bending of metal

Hydraulic sheet ejector – simplifies handling of finished products

Electronic balancing system – guarantees synchronized movement of rollers for maximum accuracy

Hydraulic side supports – support large parts during bending

Adjustable working speed – allows adjusting the process for different materials

You can purchase rolling machine Sahinler 4R HS-L 12-130 at KVERB

If you need high-quality and reliable rolling machines for metal bending, consider modern motorized models. They combine top performance, precision, and ease of control, making them the perfect choice for various production tasks.

Rolling machines for metal bending are widely used in mechanical engineering, production of ventilation systems, construction structures, pipes, and other metal products.

We offer rolling machines from leading manufacturers that meet modern quality and safety standards. We also offer a wide selection of metalworking equipment, including bending machines, mechanical and electrical machines for metal bending, capable of handling the most complex tasks.

In addition to sales, our company provides service maintenance of rolling machines, as well as technical support and consultations for selecting and configuring equipment. Our specialists guarantee the durability and uninterrupted operation of the machines, providing professional service at all stages of operation.

Choose reliable rolling machines for metal bending – and you will achieve high quality, efficiency, and durability in your production process.

The model is used for shaping metal blanks into cylindrical, conical, and other shapes. It is applied in the production of pipes, tanks, ventilation ducts, metal structures, and other products.

Sahinler 4R HS-L 12-130 is suitable for enterprises in mechanical engineering, shipbuilding, construction, and metalworking. It ensures high precision when working with various types of metals and is ideal for both mass and custom production.

Technical specifications of rolling machine Sahinler 4R HS-L 12-130

Useful bending length 1270 mm

Maximum sheet thickness for pre-bending 5 mm

Maximum sheet thickness for rolling 4 mm

Maximum stainless steel thickness for rolling 3 mm

Upper roller diameter 130 mm

Side roller diameter 130 mm

Motor power 3 kW

Working speed 1.5–6 m/min

Dimensions (LxWxH) 3350x1100x1150 mm

Weight 2350 kg

Advantages and features of rolling machine Sahinler 4R HS-L 12-130

Increased power allows processing thick metal with high precision

Optimized control system – the option to install NC or CNC for automation

Four-roll design – ensures even pressure and high-quality bending of metal

Hydraulic sheet ejector – simplifies handling of finished products

Electronic balancing system – guarantees synchronized movement of rollers for maximum accuracy

Hydraulic side supports – support large parts during bending

Adjustable working speed – allows adjusting the process for different materials

You can purchase rolling machine Sahinler 4R HS-L 12-130 at KVERB

If you need high-quality and reliable rolling machines for metal bending, consider modern motorized models. They combine top performance, precision, and ease of control, making them the perfect choice for various production tasks.

Rolling machines for metal bending are widely used in mechanical engineering, production of ventilation systems, construction structures, pipes, and other metal products.

We offer rolling machines from leading manufacturers that meet modern quality and safety standards. We also offer a wide selection of metalworking equipment, including bending machines, mechanical and electrical machines for metal bending, capable of handling the most complex tasks.

In addition to sales, our company provides service maintenance of rolling machines, as well as technical support and consultations for selecting and configuring equipment. Our specialists guarantee the durability and uninterrupted operation of the machines, providing professional service at all stages of operation.

Choose reliable rolling machines for metal bending – and you will achieve high quality, efficiency, and durability in your production process.

Specifications Metal rolling machine Sahinler 4R HS-L 12-130

- Working speed 1.5-6 m/min

- Drive Type Electromechanical

- Engine power 30 kW

- Working length 1270 mm

- Shaft diameter 130/130 mm

- WEIGHT 2350 кг

- LENGTH 3350 mm

- WIDTH 1100 mm

- HEIGHT 1150 mm

Reviews

There are no reviews on this product yet, be the first

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21