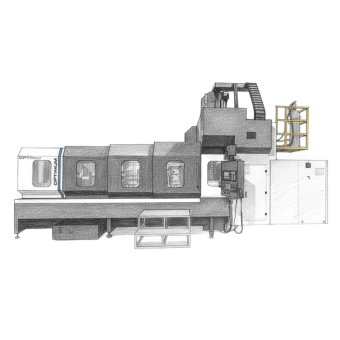

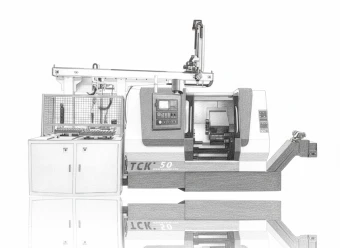

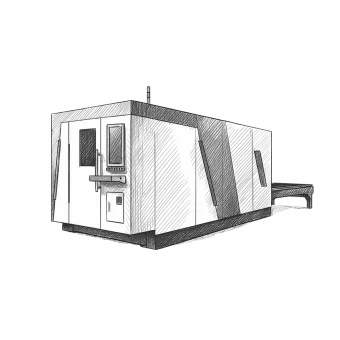

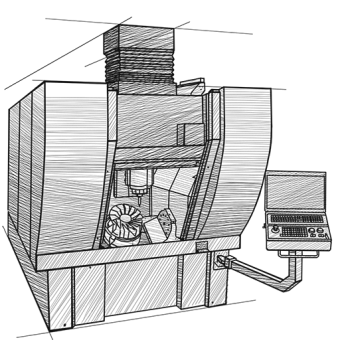

CNC turn-milling machining center Alzmetall GS 800/5-FDT

SKU 1920066

0 reviews

In stock

ALZMETALL

Shipping

- Pickup (Self-pickup) (For free)

- New POST (Up to 100 UAN)

- Meest (Up to 100 UAN)

Payment

- Payment upon receipt

- Cash payment

- Payment by bank details

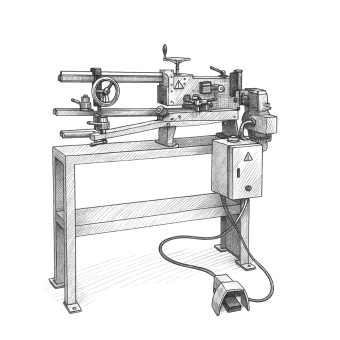

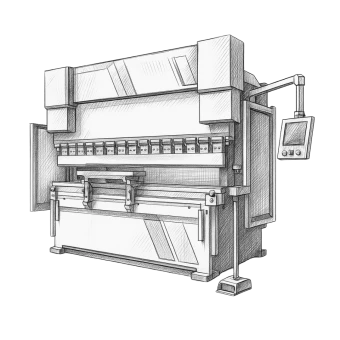

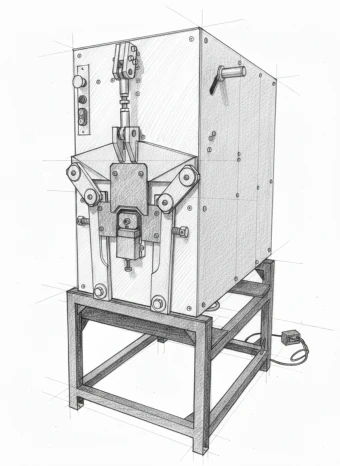

CNC turn-milling machining center Alzmetall GS 800/5-FDT is modern equipment designed for performing complex metalworking tasks. Combining drilling, milling, turning, and grinding functions in a single setup, this machine ensures maximum precision and efficiency in production processes.

The machining center is ideal for enterprises manufacturing high-precision parts for aerospace, automotive, medical, and other industries. The 5-axis machine allows processing parts with complex geometry at high accuracy, making it an indispensable tool for producing components that require quality and reliability.

Technical specifications:

Working range along axes: X – 660 mm, Y – 800 mm, Z – 550 mm

Maximum table load capacity: 500 kg

Interference circle diameter: 800 mm

Drive power at 25% ED: 13 kW

Maximum spindle speed: 10,000 rpm

Tool holder: HSK-T63

Torque at 25% ED: 80 Nm

Rapid traverse speed along axes: 75 m/min

Advantages and features:

Hybrid processing allows drilling, milling, turning, and grinding in a single setup, reducing retooling time.

High structural rigidity is ensured by components made of gray and spheroidal cast iron, guaranteeing stability and durability.

The innovative drive system with triple torque drives for A and C axes provides precise and fast positioning.

The ergonomic design simplifies access to the working area and control elements, making maintenance and setup easier.

You can purchase the CNC turn-milling machining center Alzmetall GS 800/5-FDT from the company KVERB.

We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the CNC turn-milling machining center Alzmetall GS 800/5-FDT.

The machining center is ideal for enterprises manufacturing high-precision parts for aerospace, automotive, medical, and other industries. The 5-axis machine allows processing parts with complex geometry at high accuracy, making it an indispensable tool for producing components that require quality and reliability.

Technical specifications:

Working range along axes: X – 660 mm, Y – 800 mm, Z – 550 mm

Maximum table load capacity: 500 kg

Interference circle diameter: 800 mm

Drive power at 25% ED: 13 kW

Maximum spindle speed: 10,000 rpm

Tool holder: HSK-T63

Torque at 25% ED: 80 Nm

Rapid traverse speed along axes: 75 m/min

Advantages and features:

Hybrid processing allows drilling, milling, turning, and grinding in a single setup, reducing retooling time.

High structural rigidity is ensured by components made of gray and spheroidal cast iron, guaranteeing stability and durability.

The innovative drive system with triple torque drives for A and C axes provides precise and fast positioning.

The ergonomic design simplifies access to the working area and control elements, making maintenance and setup easier.

You can purchase the CNC turn-milling machining center Alzmetall GS 800/5-FDT from the company KVERB.

We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the CNC turn-milling machining center Alzmetall GS 800/5-FDT.

Specifications CNC turn-milling machining center Alzmetall GS 800/5-FDT

- Spindle speed 18000 RPM

- Max. Tool Diameter(Full/Empty) 80/150 mm

- Max. Tool Length 300

- Max. Tool Weight 10

- Max. Travel For X Axis 660

- Max. Travel For Y Axis 800

- Max. Travel For Z Axis 550

- Spindle Nose To Table 100/650 mm

- Spindle Motor Power 24 kW

- Number of axes 5

- WEIGHT 11200

Reviews

There are no reviews on this product yet, be the first

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21