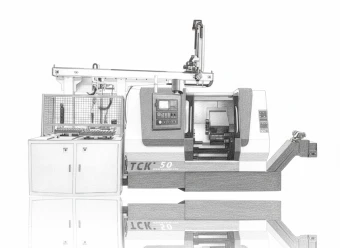

CNC lathe machining center TCK-40

SKU 1920137

0 reviews

In stock

WEIDA

Shipping

- Pickup (Self-pickup) (For free)

- New POST (Up to 100 UAN)

- Meest (Up to 100 UAN)

Payment

- Payment upon receipt

- Cash payment

- Payment by bank details

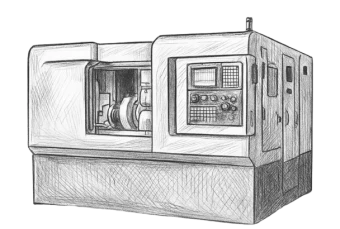

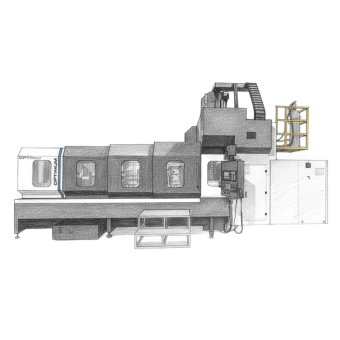

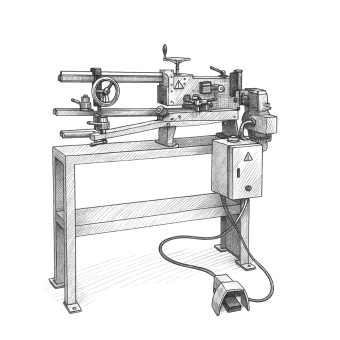

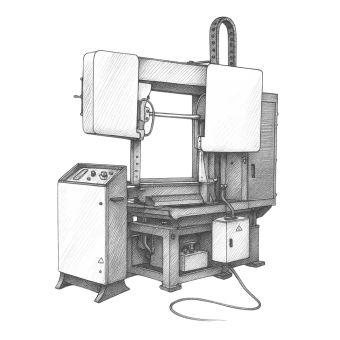

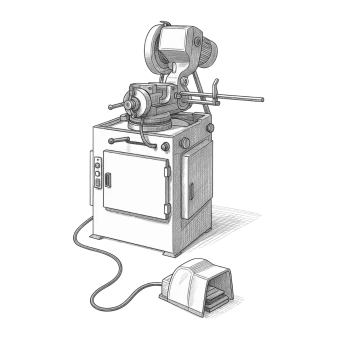

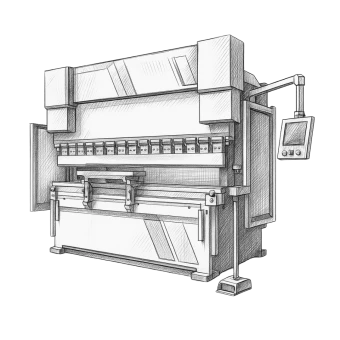

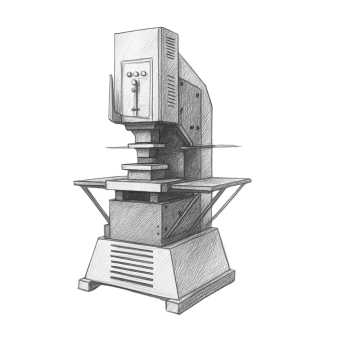

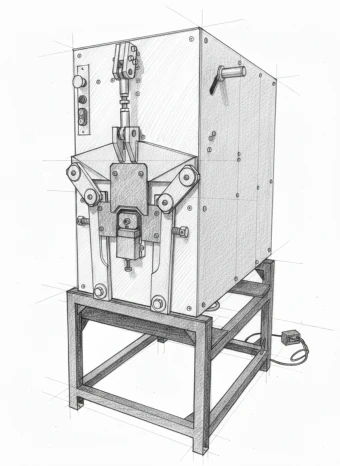

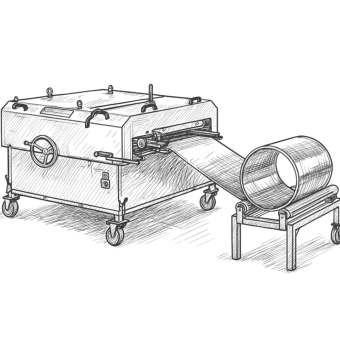

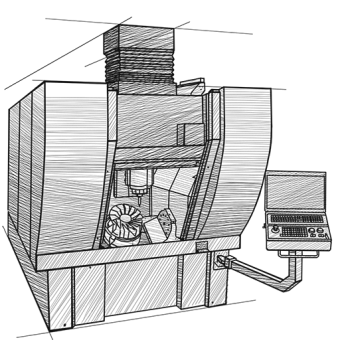

CNC lathe machining center TCK-40 is compact and reliable equipment designed for precise machining of metal workpieces. The high spindle speed and motor power allow efficient handling of tasks of varying complexity. The 45° slant bed ensures operator convenience and improves chip removal, making the machine suitable for serial production. Its compact size and versatility make TCK-40 an excellent choice for small and medium-sized enterprises.

TCK-40 is ideal for machining disc and shaft workpieces made from various materials. The machine is used in mechanical engineering, metalworking, and other industries where high precision and productivity are required.

Technical specifications:

Maximum machining diameter over bed: Ø450 mm.

Maximum machining diameter: Ø400 mm (disc workpieces with length ≤ 80).

Maximum machining diameter over carriage: Ø220 mm.

Maximum machining length: 500 mm.

Spindle nose type (internal taper): A2-6 (MT6).

Spindle speed: 4500 rpm.

Spindle motor power: 7.5 / 11 kW.

Spindle bore diameter: Ø66 mm.

Bar diameter: Ø52 mm.

Travel along X axis: 250 mm.

Torque of X-axis motor: ≥10 N·m.

Travel along Z axis: 530 mm.

Torque of Z-axis motor: ≥10 N·m.

Tailstock feed method: saddle movement.

Hydraulic chuck size: 8” / 10” (optional).

Turret type: hydraulic / servo drive.

Tool size: 25×25 (depending on turret type).

Tailstock quill diameter: Ø72 mm.

Tailstock quill travel: 100 mm.

Maximum tailstock travel: 400 mm.

Bed type and tilt angle: monolithic construction with 45° slant, linear guideways.

Advantages and features:

TCK-40 features high spindle speed and motor power, enabling efficient machining of various materials.

The compact machine design ensures convenient placement even in enterprises with limited space.

The hydraulic chuck securely clamps workpieces, ensuring machining accuracy.

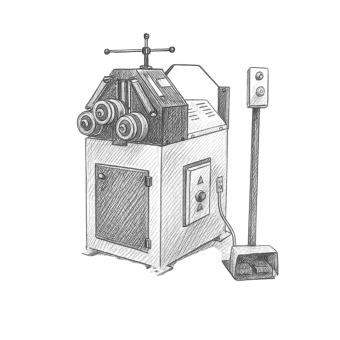

The turret with hydraulic or servo drive accelerates tool changes, increasing productivity.

Servomotors on the X and Z axes provide smooth and precise movement, minimizing errors.

The 45° slant bed improves chip removal, making work more efficient and convenient.

You can purchase the CNC lathe machining center TCK-40 from the company KVERB.

We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the CNC lathe machining center TCK-40.

TCK-40 is ideal for machining disc and shaft workpieces made from various materials. The machine is used in mechanical engineering, metalworking, and other industries where high precision and productivity are required.

Technical specifications:

Maximum machining diameter over bed: Ø450 mm.

Maximum machining diameter: Ø400 mm (disc workpieces with length ≤ 80).

Maximum machining diameter over carriage: Ø220 mm.

Maximum machining length: 500 mm.

Spindle nose type (internal taper): A2-6 (MT6).

Spindle speed: 4500 rpm.

Spindle motor power: 7.5 / 11 kW.

Spindle bore diameter: Ø66 mm.

Bar diameter: Ø52 mm.

Travel along X axis: 250 mm.

Torque of X-axis motor: ≥10 N·m.

Travel along Z axis: 530 mm.

Torque of Z-axis motor: ≥10 N·m.

Tailstock feed method: saddle movement.

Hydraulic chuck size: 8” / 10” (optional).

Turret type: hydraulic / servo drive.

Tool size: 25×25 (depending on turret type).

Tailstock quill diameter: Ø72 mm.

Tailstock quill travel: 100 mm.

Maximum tailstock travel: 400 mm.

Bed type and tilt angle: monolithic construction with 45° slant, linear guideways.

Advantages and features:

TCK-40 features high spindle speed and motor power, enabling efficient machining of various materials.

The compact machine design ensures convenient placement even in enterprises with limited space.

The hydraulic chuck securely clamps workpieces, ensuring machining accuracy.

The turret with hydraulic or servo drive accelerates tool changes, increasing productivity.

Servomotors on the X and Z axes provide smooth and precise movement, minimizing errors.

The 45° slant bed improves chip removal, making work more efficient and convenient.

You can purchase the CNC lathe machining center TCK-40 from the company KVERB.

We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the CNC lathe machining center TCK-40.

Specifications CNC lathe machining center TCK-40

- Max. swing over bed 450

- Max. swing over slider 220

Reviews

There are no reviews on this product yet, be the first

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21