MANUAL DECOILERS

Filters

Filters

PRODUCTS YOU HAVE VIEWED

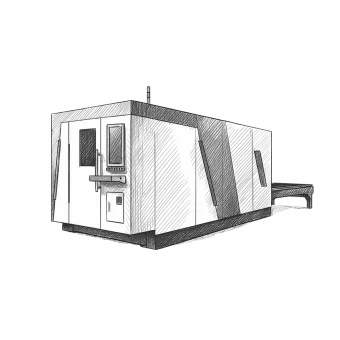

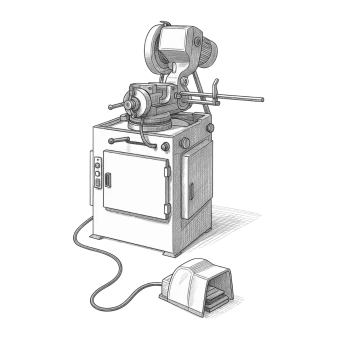

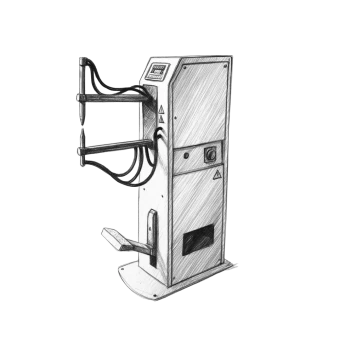

Coil Metal Decoiler is industrial equipment designed to feed coiled sheet metal into the next stages of processing such as cutting, stamping, profiling, and more. Its main function is to unwind the coil smoothly and consistently without damaging the material, ensuring a continuous production flow. Decoilers are essential in both automated and semi-automated metalworking lines, as well as in manual setups.

A metal coil decoiler can be manual, electromechanical, or cantilever-type depending on the coil’s size, required feeding speed, and automation level.

Types of Coil Decoilers and Their Features

Depending on their construction and feeding method, there are several common types:

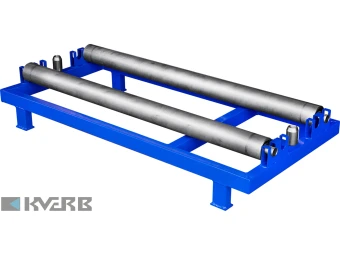

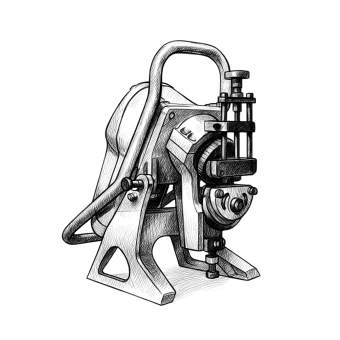

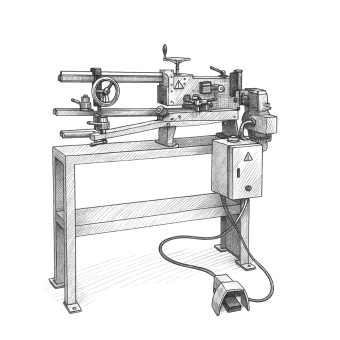

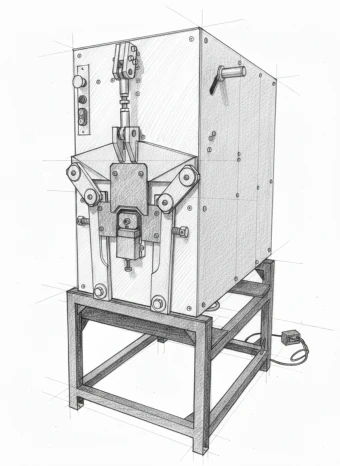

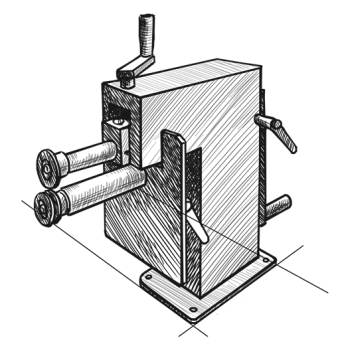

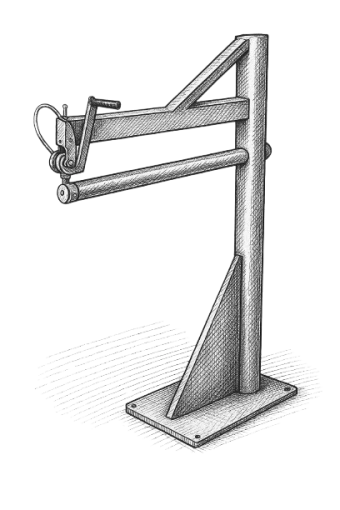

Manual Coil Decoilers

Ideal for small-scale production and workshops. These units are simple to use, require no power connection, and are easily transportable. Examples:

Manual Coil Decoiler AC-125/1000 by Bří Švarcové.

Manual Decoiler RL 1000 by Mazanek.

Manual Decoiler RW1.25 by Zakmet.

Advantages:

Low cost.

Easy to install and operate.

Compact size.

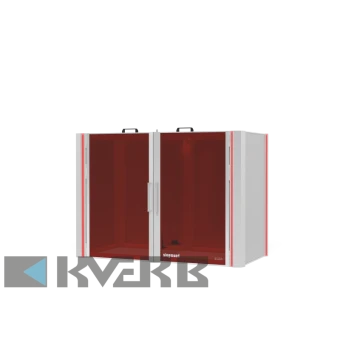

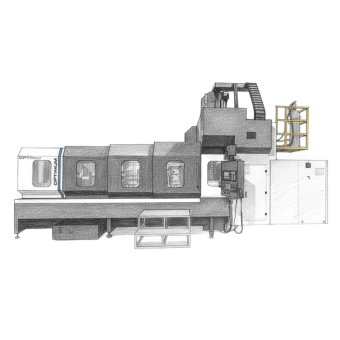

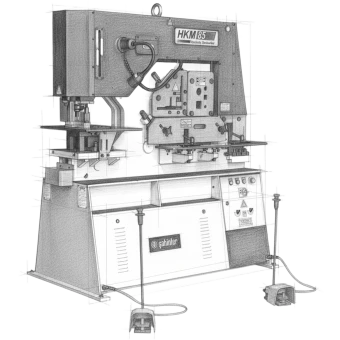

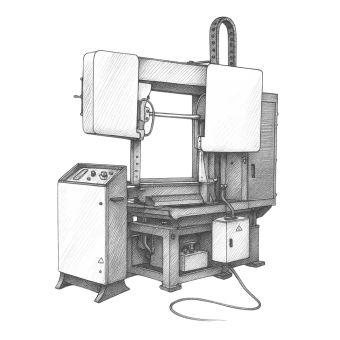

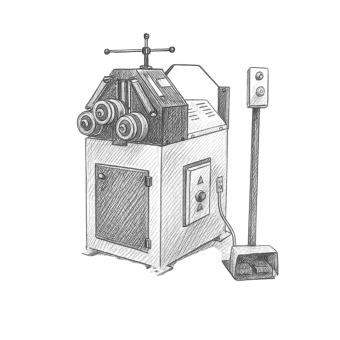

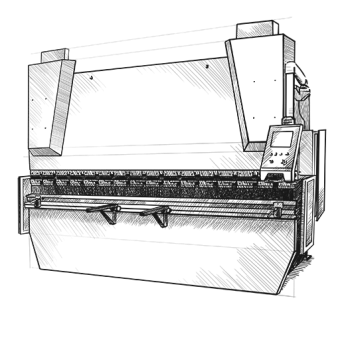

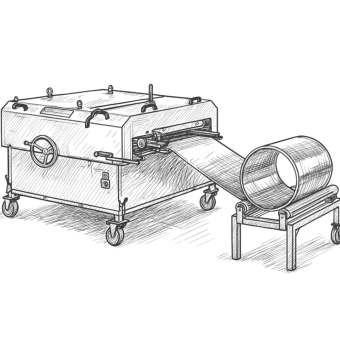

Electromechanical Coil Decoilers

Used in automated lines, they provide a stable feed rate and are perfect for batch or high-volume production. Examples:

Electromechanical Decoiler RM 1250 by Mazanek.

Electromechanical Decoiler SENTE UNC 7000-M.

Advantages:

Increased productivity.

Suitable for heavy coil weights.

Can be synchronized with production lines

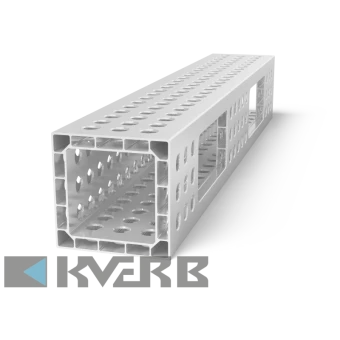

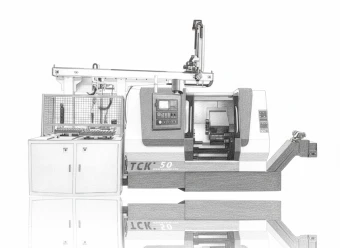

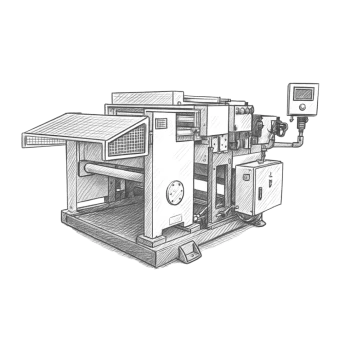

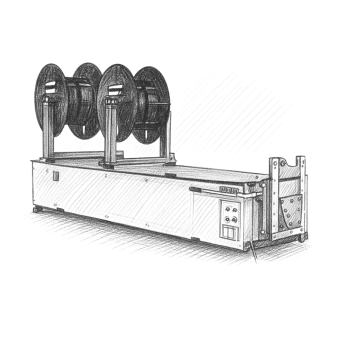

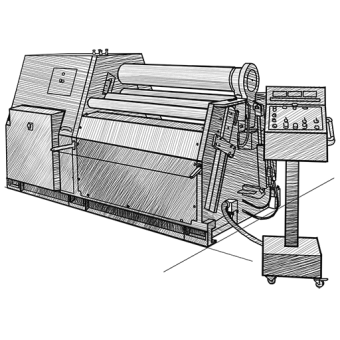

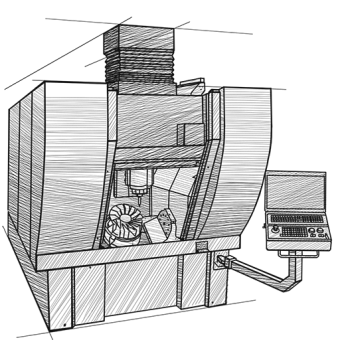

Cantilever Coil Decoilers

Built for heavy-duty industrial use, commonly found in production of metal roofing, ventilation ducts, and large profiles. Examples:

Cantilever Decoiler 2t by Swah.

Electromechanical Cantilever Decoiler 5t by Swah.

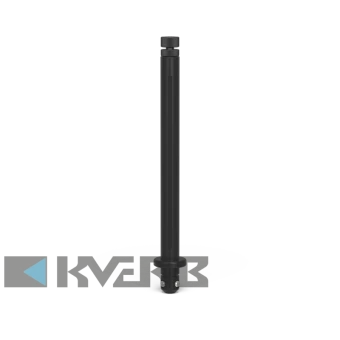

When selecting a coil decoiler, consider the following:

Coil width and weight.

Outer and inner coil diameter.

Drive type — manual or motorized.

Presence of a pressure roller.

Compatibility with cutting or profiling lines.

Manufacturer reliability and available service.

Manual decoilers are sufficient for low-volume tasks. For continuous feeding in a production line, an automated coil metal decoiler with motorized drive is recommended.

KVERB offers a wide selection of coil decoilers from top manufacturers, available across Ukraine. In-stock and custom orders include:

Manufacturers:

Bří Švarcové (Czech Republic) — durable and compact manual models.

Mazanek (Poland) — manual and motorized decoilers for various production needs.

Zakmet (Poland) — affordable solutions for workshops and small plants.

Swah (Czech Republic) — cantilever decoilers with high load capacity.

SENTE (Turkey) — professional-grade electromechanical units.

MAAD (Poland) — reliable European-level industrial equipment.

Why Choose KVERB?

Official distribution and warranty service.

Nationwide delivery across Ukraine.

Tailored equipment recommendations.

Technical support, setup, and maintenance.

Order your coil metal decoiler from KVERB’s online catalog today — we’ll help you find the perfect match based on your requirements, budget, and production goals.

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21