ПЛОСКОШЛІФУВАЛЬНІ ВЕРСТАТИ З РУХОМОЮ КОЛОНОЮ

Filters

Filters

PRODUCTS YOU HAVE VIEWED

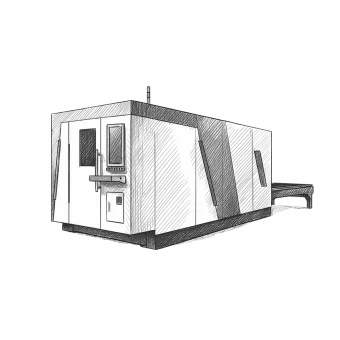

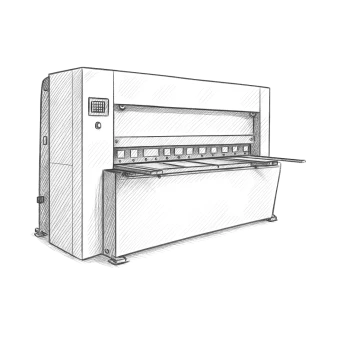

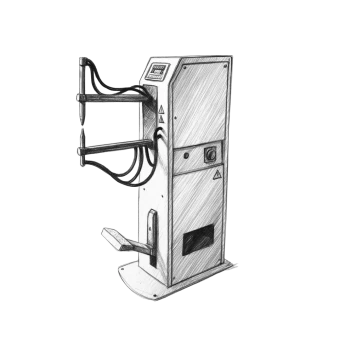

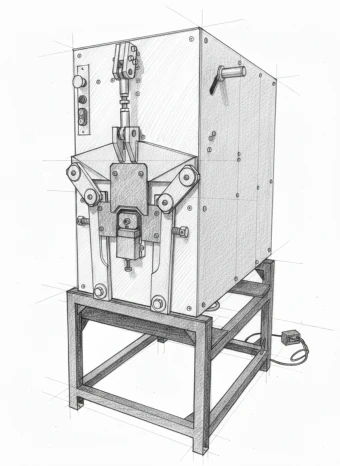

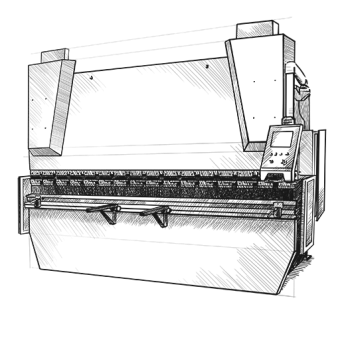

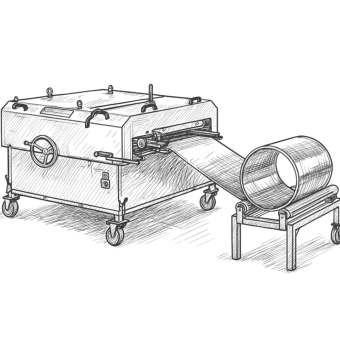

Surface Grinding Machine — Professional Precision Finishing of Metal.

A surface grinding machine is specialized equipment designed for high-precision machining of flat metal surfaces. Its main purpose is to achieve minimal roughness, perfect geometry, and high dimensional accuracy. This is the final stage of machining, which is especially critical for toolmaking, aviation, mechanical engineering, and defense production.

Surface grinding machines ensure linear movement of the grinding wheel across the workpiece surface, removing a minimal layer of metal. This allows for:

High precision: tolerances up to 0.005 mm.

Smooth surface without cutting marks.

Consistency in geometry from part to part.

Minimal thermal and mechanical impact on the material.

Applications:

Machining and tool shops.

Production of molds and dies.

Metal processing in aviation and automotive industries.

Machine building, instrumentation, repair workshops.

Advantages:

Works with parts of various shapes and sizes.

Reliability and stability in batch production.

Possibility of integration with CAD/CAM systems.

Choice between manual, semi-automatic, automatic, and CNC control.

When choosing a surface grinding machine for metal, it is important to consider:

Machining format: manual, semi-auto, hydraulic, CNC.

Worktable size and stroke range: depends on workpiece dimensions.

Spindle drive power and type.

Control system type: mechanical, digital, CNC.

Production tasks: small batch or mass production.

Grinding wheel and feed characteristics.

Which surface grinding machine models are offered by KVERB.

In KVERB's catalog, you will find over 80 models of surface grinding machines.

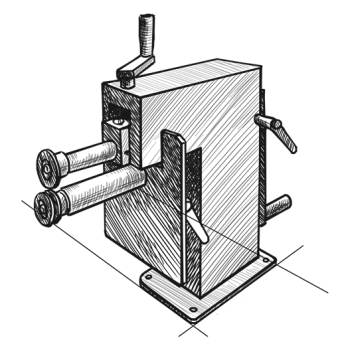

Manual models:

EQUIPTOP ESG-618M, UF-618M, UF-818M — easy to use, ideal for educational and auxiliary production.

Semi-automatic and hydraulic models:

EQUIPTOP ESG-3A818, ESG-3A1020, ESG-3A1224 — optimal for serial processing with minimal labor costs.

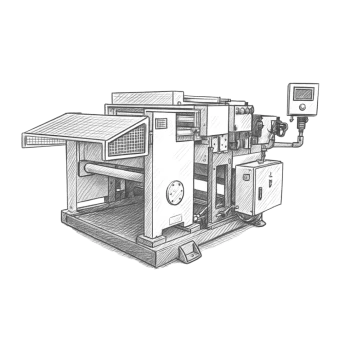

Automatic and digital machines:

ESG-818TD NC, ESG-1224TD NC/ADC, ESG-1228ASDII, ESG-1236ASDII — panel-controlled, precise parameter setting, ideal for mass production.

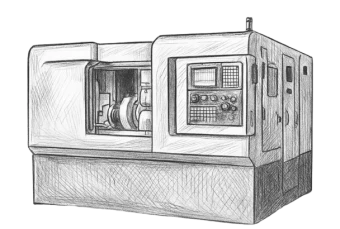

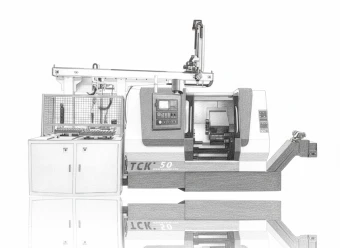

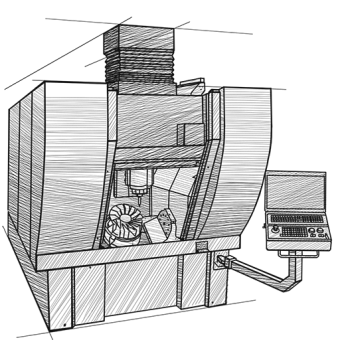

CNC machines:

ESG-2480TDNC/CNC, ESG-32120TDNC/CNC, ERG-600, ESG-104CNC — for the most complex tasks, offering repeatability, precision, and automation.

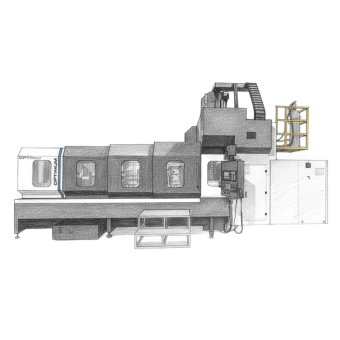

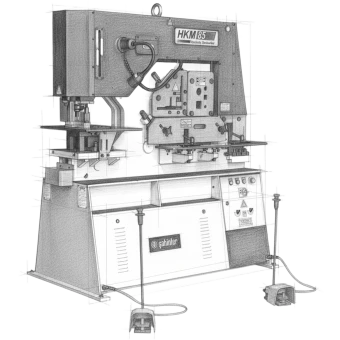

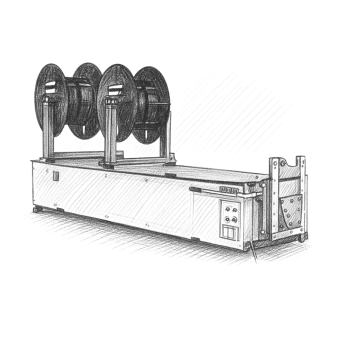

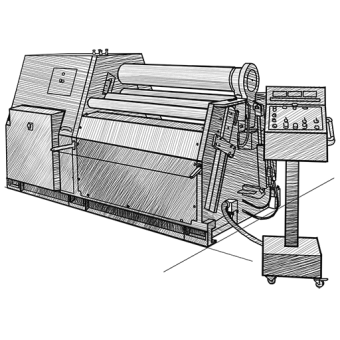

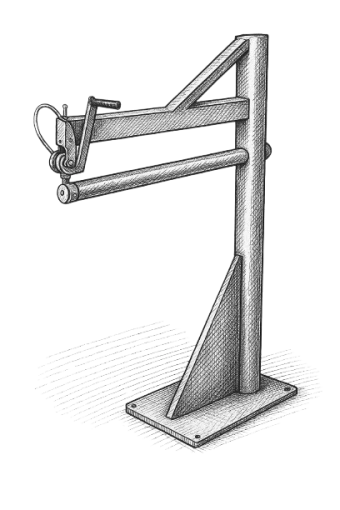

Industrial models with moving column:

ESG-24120TDNC/CNC, ESG-3260TDNC/CNC — designed for large-sized parts and long surfaces.

KVERB is the official supplier of EQUIPTOP, ERG, ECG surface grinding machines in Ukraine. We offer:

Wide selection: manual, automatic, and CNC machines.

Commissioning, training, warranty.

Machine selection tailored to your specific task.

Delivery across Ukraine — wholesale and retail.

Full documentation package, tech support, spare parts.

Buying a surface grinding machine from KVERB means investing in precision, stability, and efficiency. Contact us — and we’ll help select the best solution for your workshop.

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21