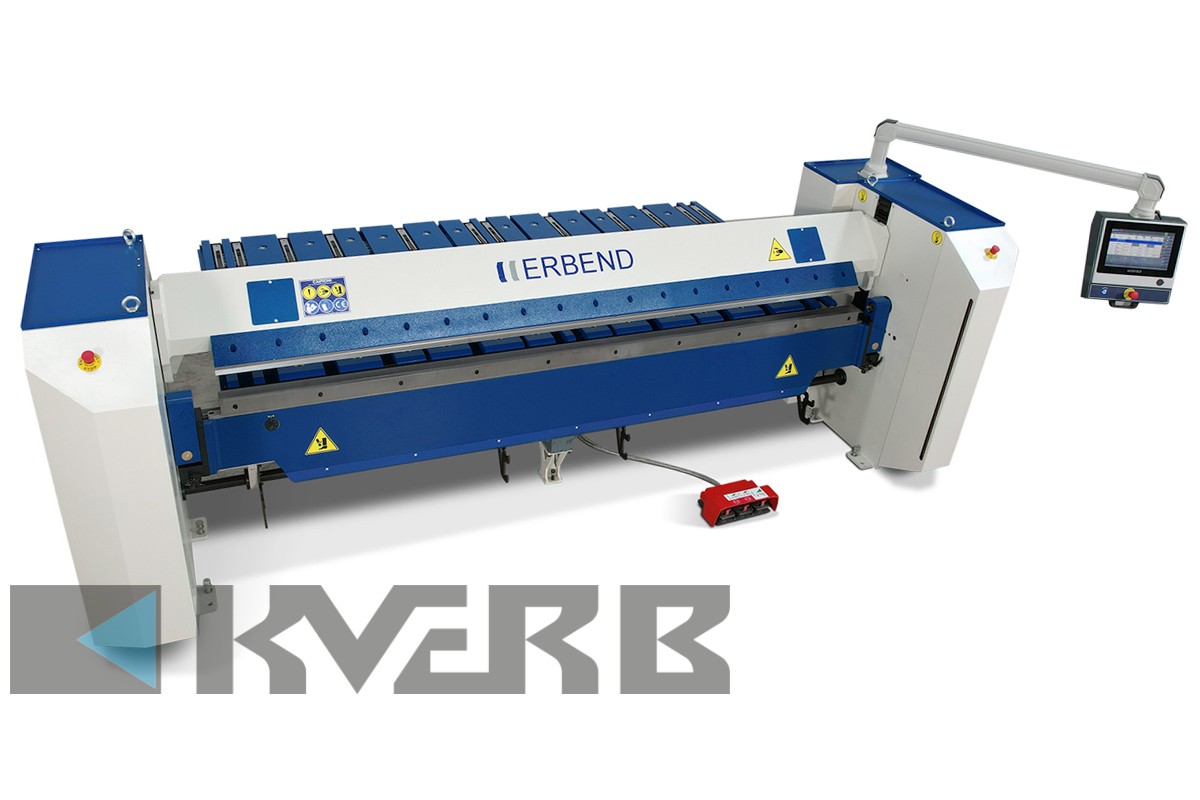

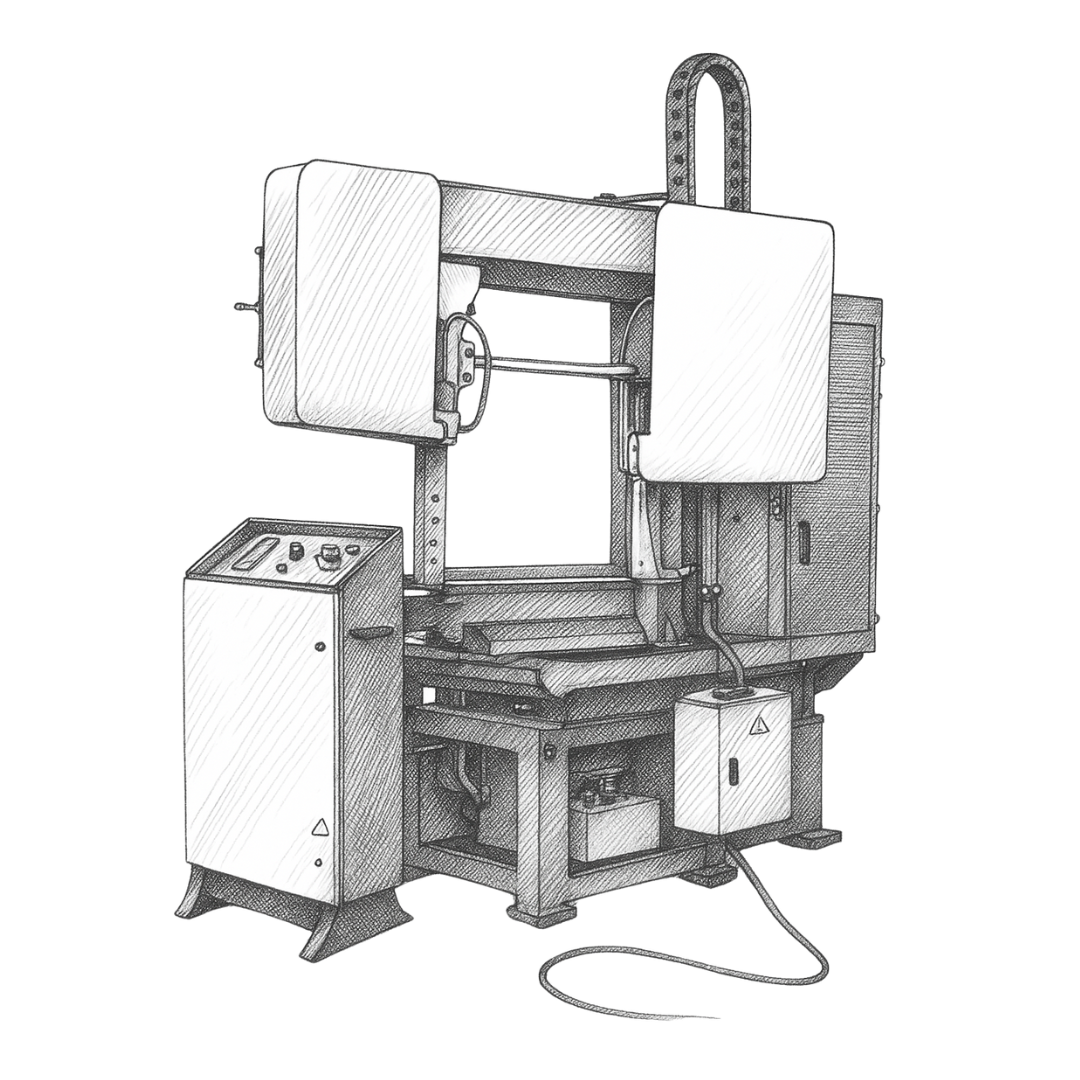

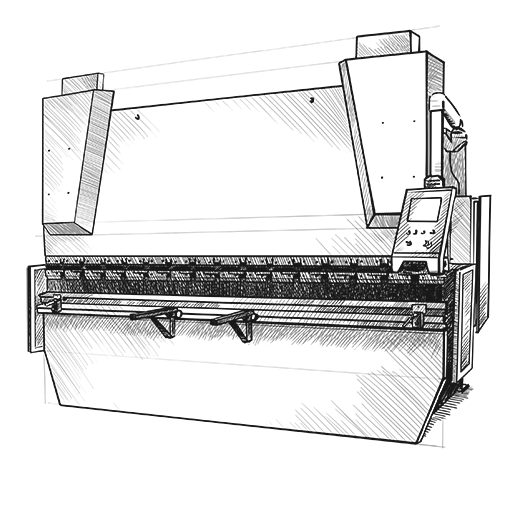

Sheet metal bending machine with electromechanical drive ERBEND MFC 2025

SKU 9090-100-021

0 reviews

In stock

ERBEND

0 uah.

Shipping

- Pickup (Self-pickup) For free

- New POST Up to 100 uan

- Meest up to 100

Payment

- Оплата при отриманні

- Готівкова оплата

- Оплата по рахунку

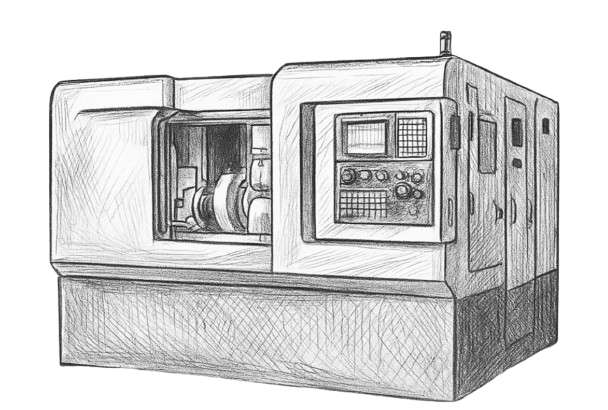

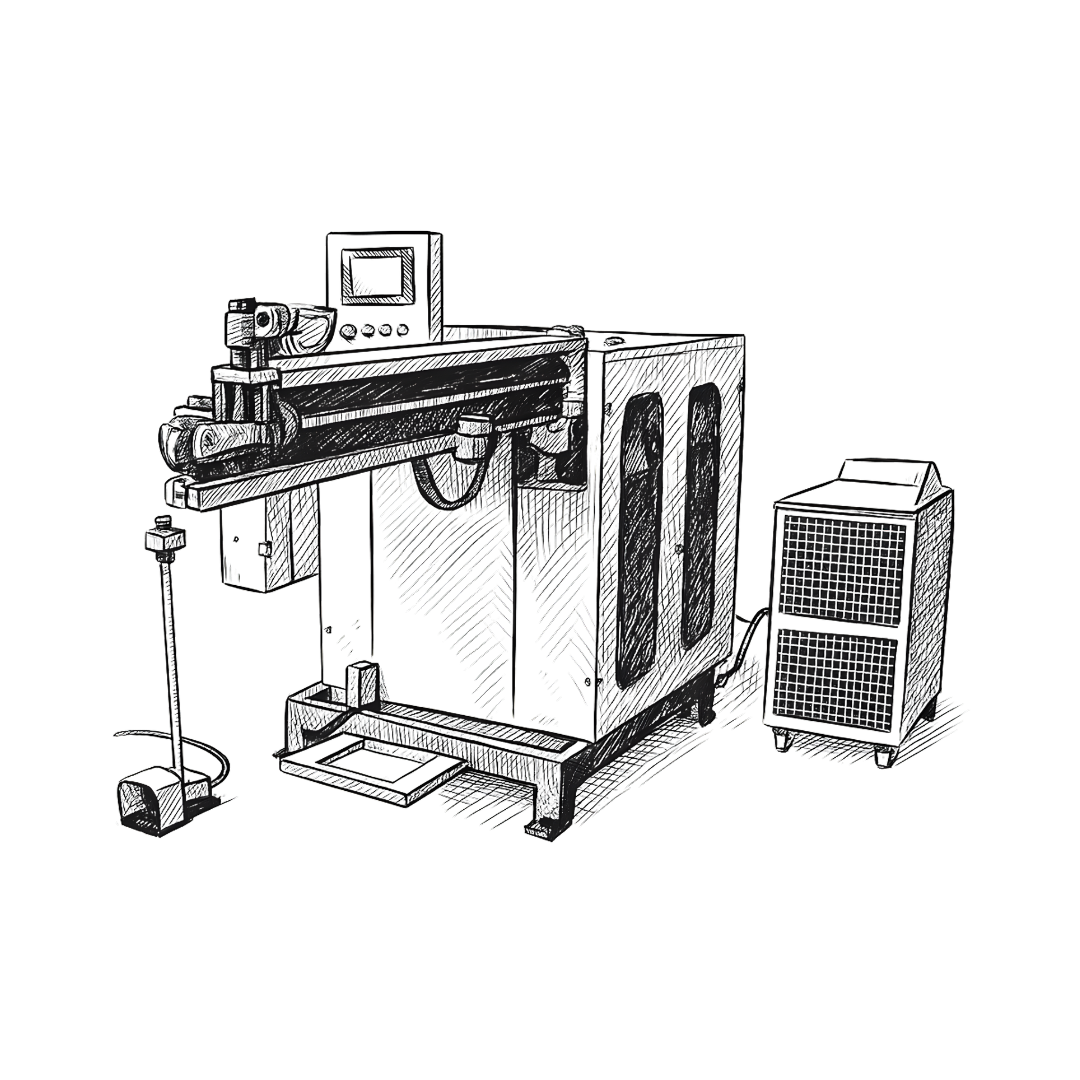

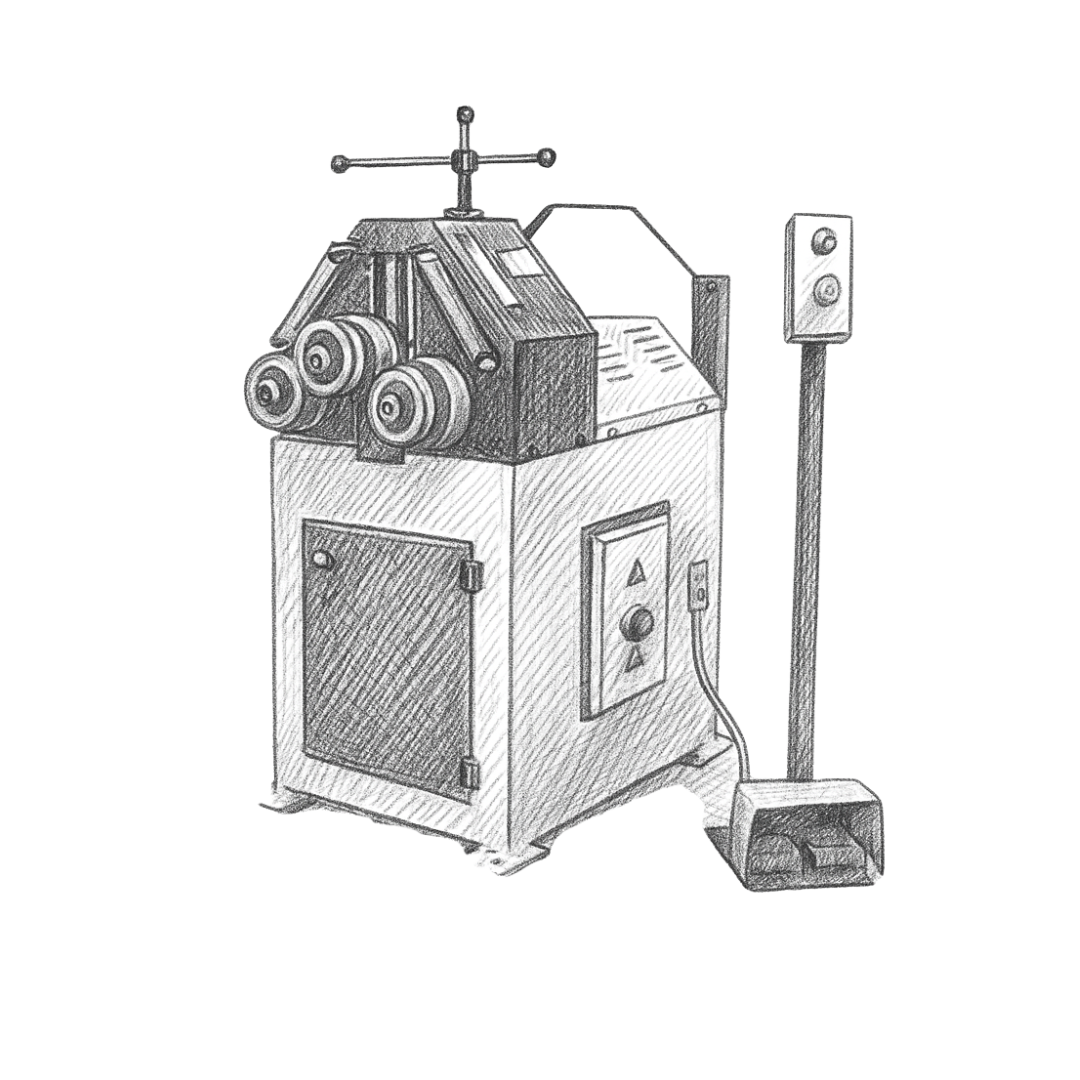

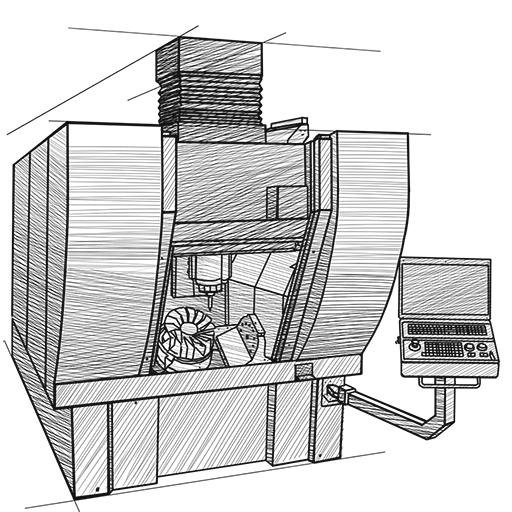

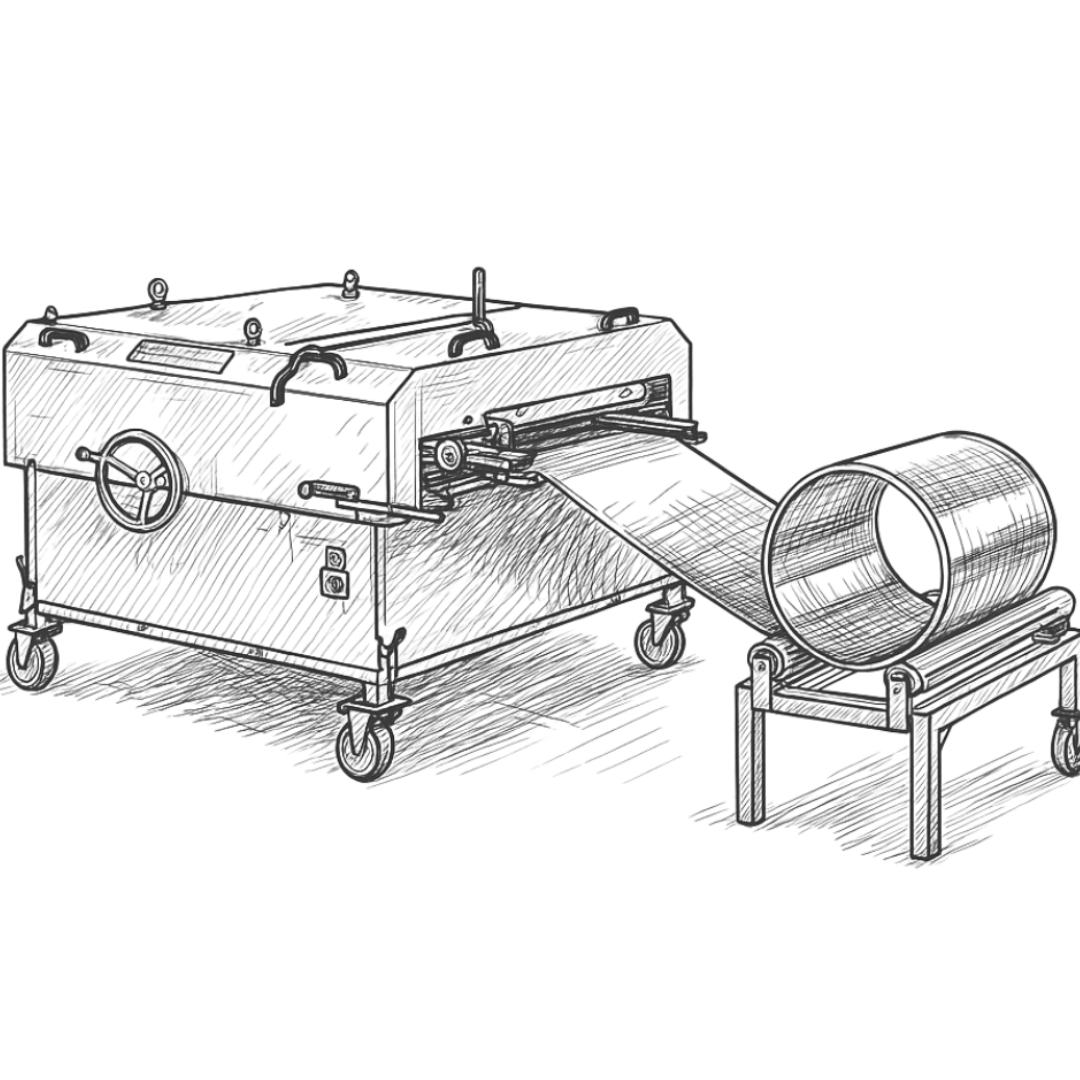

Electromechanical sheet metal bending machine ERBEND MFC 2025 – a powerful and modern solution for metal bending.

The ERBEND MFC 2025 electromechanical sheet metal bending machine is a high-tech bending machine designed for precise processing of sheet metal. This professional bending machine combines economy, ease of operation, and high productivity. With its CNC system, vertical clamping, and smooth start-up of working traverses, the bending process becomes both convenient and safe.

Who is the ERBEND MFC 2025 electromechanical bending machine suitable for?

Metalworking enterprises that require reliable equipment for bending metal.

Manufacturers of ventilation, roofing, and construction elements, where precision and stability are crucial.

Companies with serial production, where speed, automation, and safety are key.

This sheet metal bending machine is perfect for processing materials up to 3200 mm in length and up to 1.5 mm thick.

Technical specifications of the ERBEND MFC 2025 electromechanical sheet metal bending machine:

Working length: 3200 mm.

Sheet thickness for processing:

Steel – up to 1.5 mm.

Stainless steel – up to 1.2 mm.

Aluminum – up to 2.5 mm.

Maximum beam opening: 120 mm.

Machine weight: 2550 kg.

Speeds and drives:

Bending beam drive: 2.2 kW.

Clamping beam drive: 1.1 kW.

Back gauge drive: 0.4 kW.

Bending beam speed: 75°/sec.

Clamping beam speed: 70 mm/sec.

Back gauge speed: 200 mm/sec.

Warranty: 12 months.

Advantages and features of the ERBEND MFC 2025 electromechanical sheet metal bending machine:

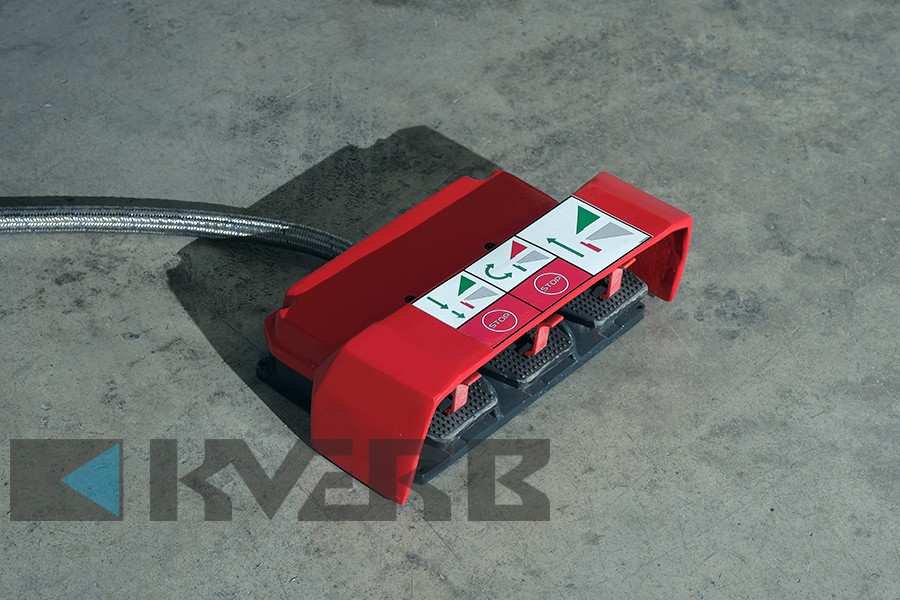

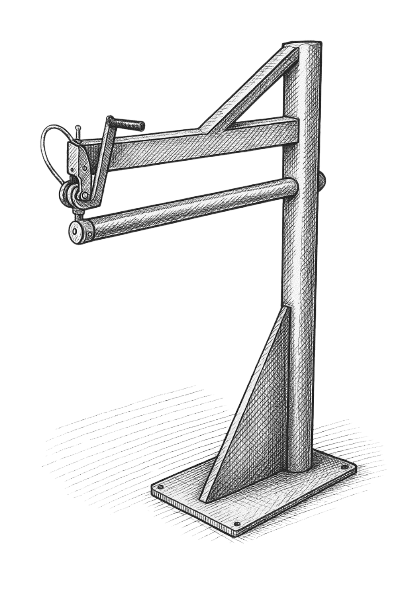

1. Ease of use:

Vertical clamping system ensures precise and reliable clamping of the sheet.

Convenient control via a digital panel with a 15.6-inch touch screen.

2. Versatility:

Works with various metals: steel, stainless steel, and aluminum.

Adjustable back gauge (6–750 mm) and additional options to expand the machine's functionality.

3. Advanced technology:

CNC system and ERFOLD 2D software for visualization and programming of bending operations.

Smooth start-up function ensures soft operation and minimizes wear.

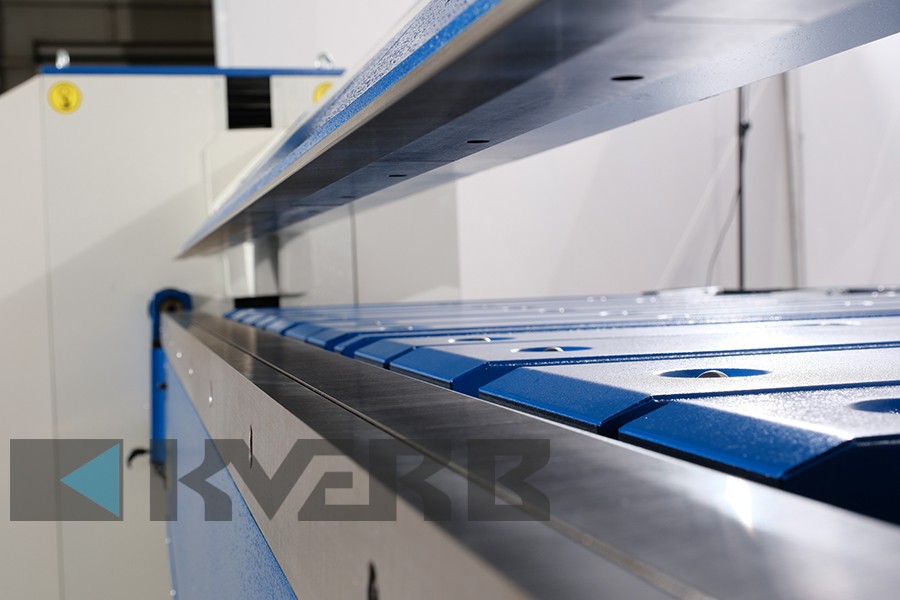

4. Reliability and durability:

Beams made of high-strength 42CrMo4 steel with laser hardening, ensuring long-term durability even under intensive use.

Why buy the ERBEND MFC 2025 electromechanical sheet metal bending machine from KVERB?

KVERB offers a wide range of automated ERBEND sheet metal bending machines, which meet modern quality standards.

Our advantages:

Guaranteed product quality.

Expert consultations and equipment selection assistance.

After-sales service and technical support.

Wide range of equipment for various tasks.

Call us now or leave a request on our website for a free consultation to purchase the ERBEND MFC 2025 electromechanical sheet metal bending machine. We will help you choose the best equipment for your production needs.

The ERBEND MFC 2025 electromechanical sheet metal bending machine is a high-tech bending machine designed for precise processing of sheet metal. This professional bending machine combines economy, ease of operation, and high productivity. With its CNC system, vertical clamping, and smooth start-up of working traverses, the bending process becomes both convenient and safe.

Who is the ERBEND MFC 2025 electromechanical bending machine suitable for?

Metalworking enterprises that require reliable equipment for bending metal.

Manufacturers of ventilation, roofing, and construction elements, where precision and stability are crucial.

Companies with serial production, where speed, automation, and safety are key.

This sheet metal bending machine is perfect for processing materials up to 3200 mm in length and up to 1.5 mm thick.

Technical specifications of the ERBEND MFC 2025 electromechanical sheet metal bending machine:

Working length: 3200 mm.

Sheet thickness for processing:

Steel – up to 1.5 mm.

Stainless steel – up to 1.2 mm.

Aluminum – up to 2.5 mm.

Maximum beam opening: 120 mm.

Machine weight: 2550 kg.

Speeds and drives:

Bending beam drive: 2.2 kW.

Clamping beam drive: 1.1 kW.

Back gauge drive: 0.4 kW.

Bending beam speed: 75°/sec.

Clamping beam speed: 70 mm/sec.

Back gauge speed: 200 mm/sec.

Warranty: 12 months.

Advantages and features of the ERBEND MFC 2025 electromechanical sheet metal bending machine:

1. Ease of use:

Vertical clamping system ensures precise and reliable clamping of the sheet.

Convenient control via a digital panel with a 15.6-inch touch screen.

2. Versatility:

Works with various metals: steel, stainless steel, and aluminum.

Adjustable back gauge (6–750 mm) and additional options to expand the machine's functionality.

3. Advanced technology:

CNC system and ERFOLD 2D software for visualization and programming of bending operations.

Smooth start-up function ensures soft operation and minimizes wear.

4. Reliability and durability:

Beams made of high-strength 42CrMo4 steel with laser hardening, ensuring long-term durability even under intensive use.

Why buy the ERBEND MFC 2025 electromechanical sheet metal bending machine from KVERB?

KVERB offers a wide range of automated ERBEND sheet metal bending machines, which meet modern quality standards.

Our advantages:

Guaranteed product quality.

Expert consultations and equipment selection assistance.

After-sales service and technical support.

Wide range of equipment for various tasks.

Call us now or leave a request on our website for a free consultation to purchase the ERBEND MFC 2025 electromechanical sheet metal bending machine. We will help you choose the best equipment for your production needs.

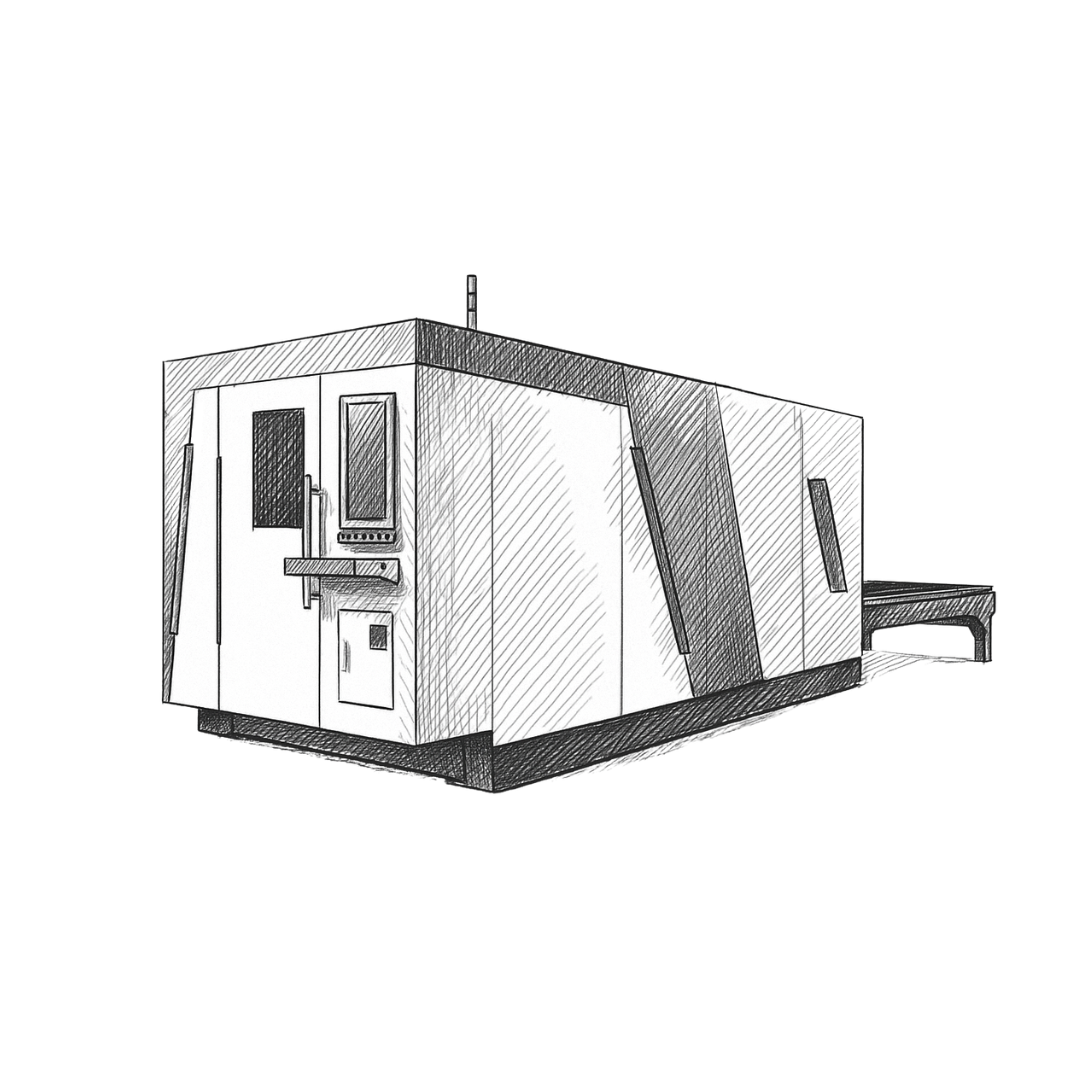

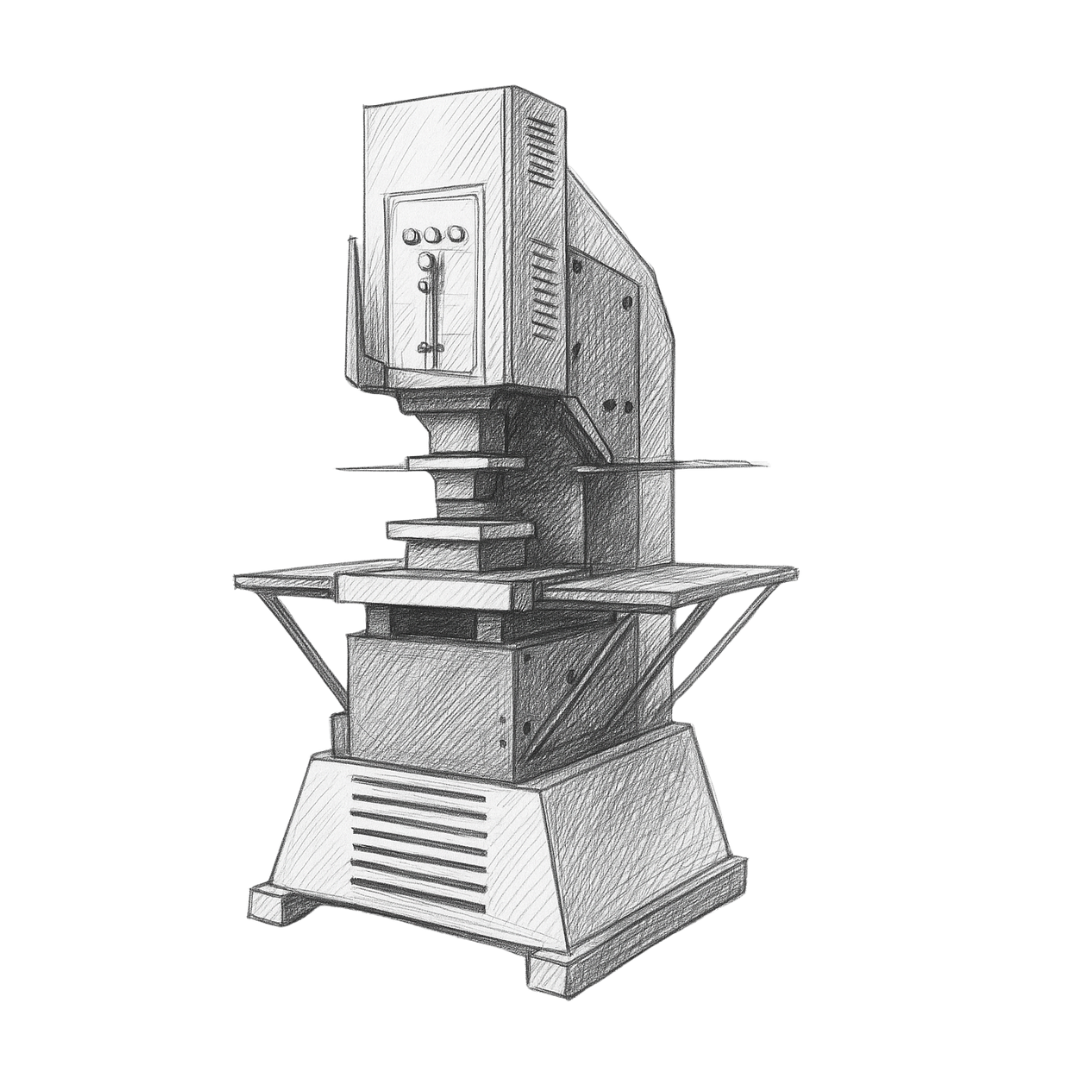

Specifications Sheet metal bending machine with electromechanical drive ERBEND MFC 2025

- Machine drive type Electromechanical

- Thickness of processed sheet 2.5 mm

- Working length of the machine 2050 mm

- Maximum bend angle 150°

- WEIGHT 2550 kg

- LENGTH 3350 mm

- WIDTH 2100 mm

- HEIGHT 1860 mm

Reviews

There are no reviews on this product yet, be the first

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21