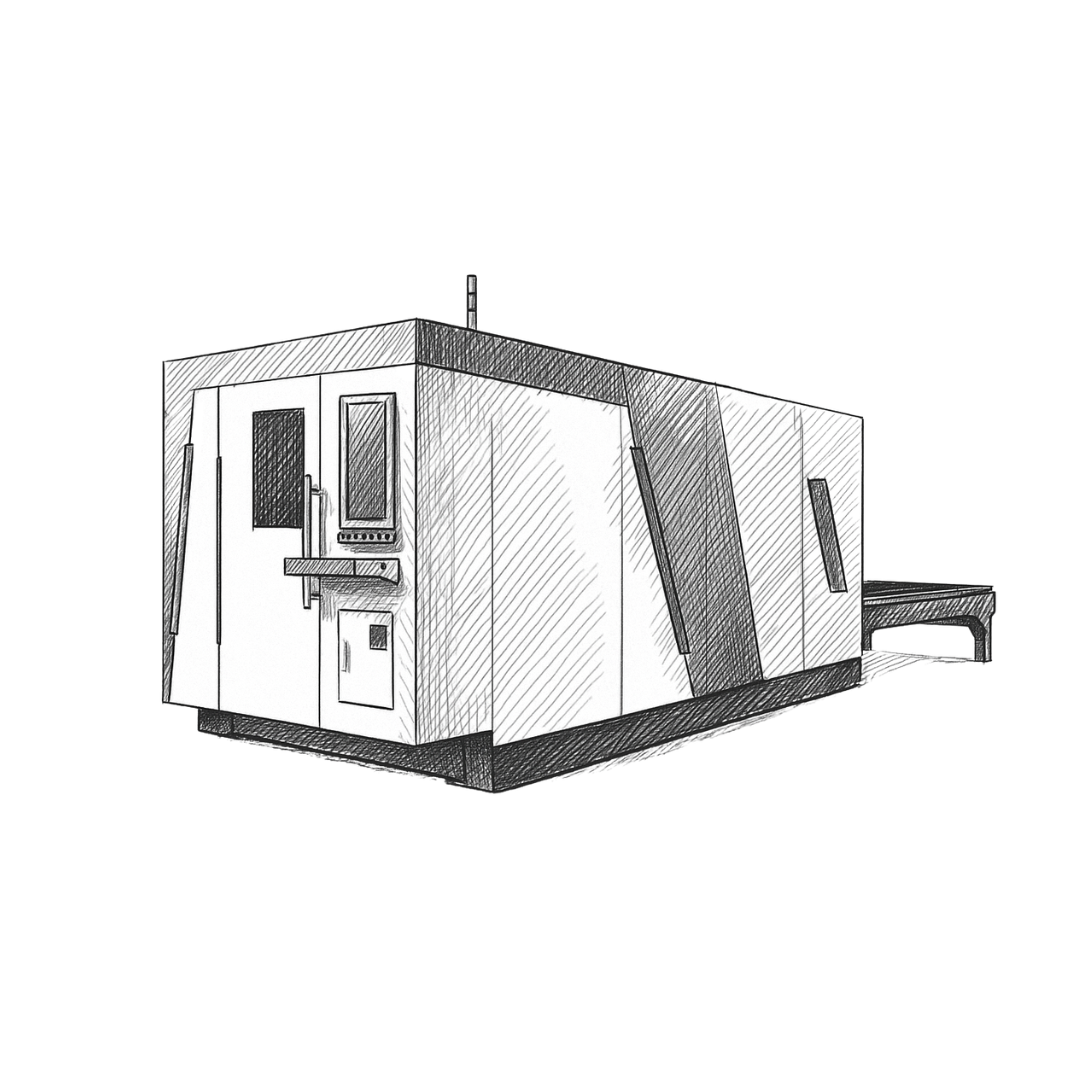

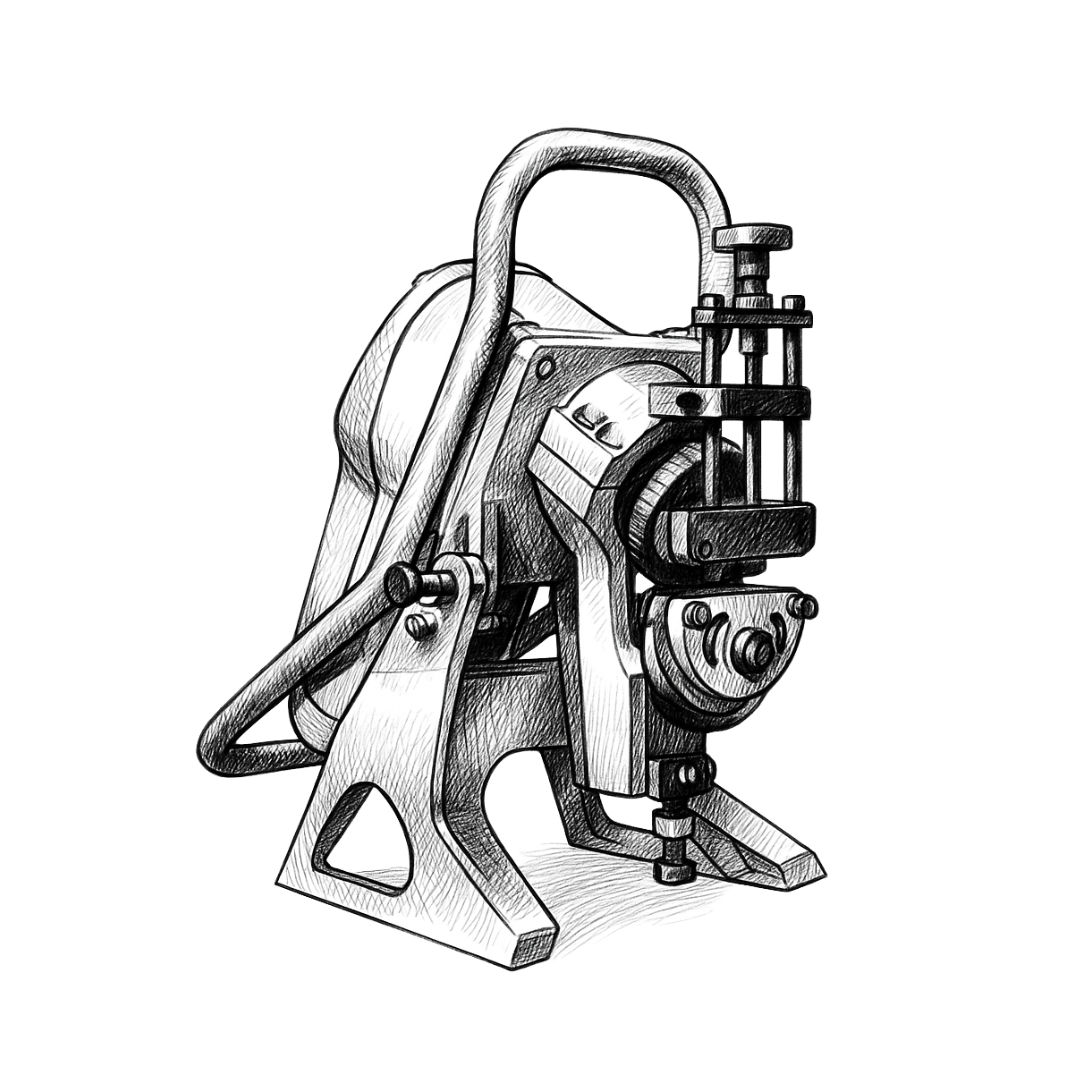

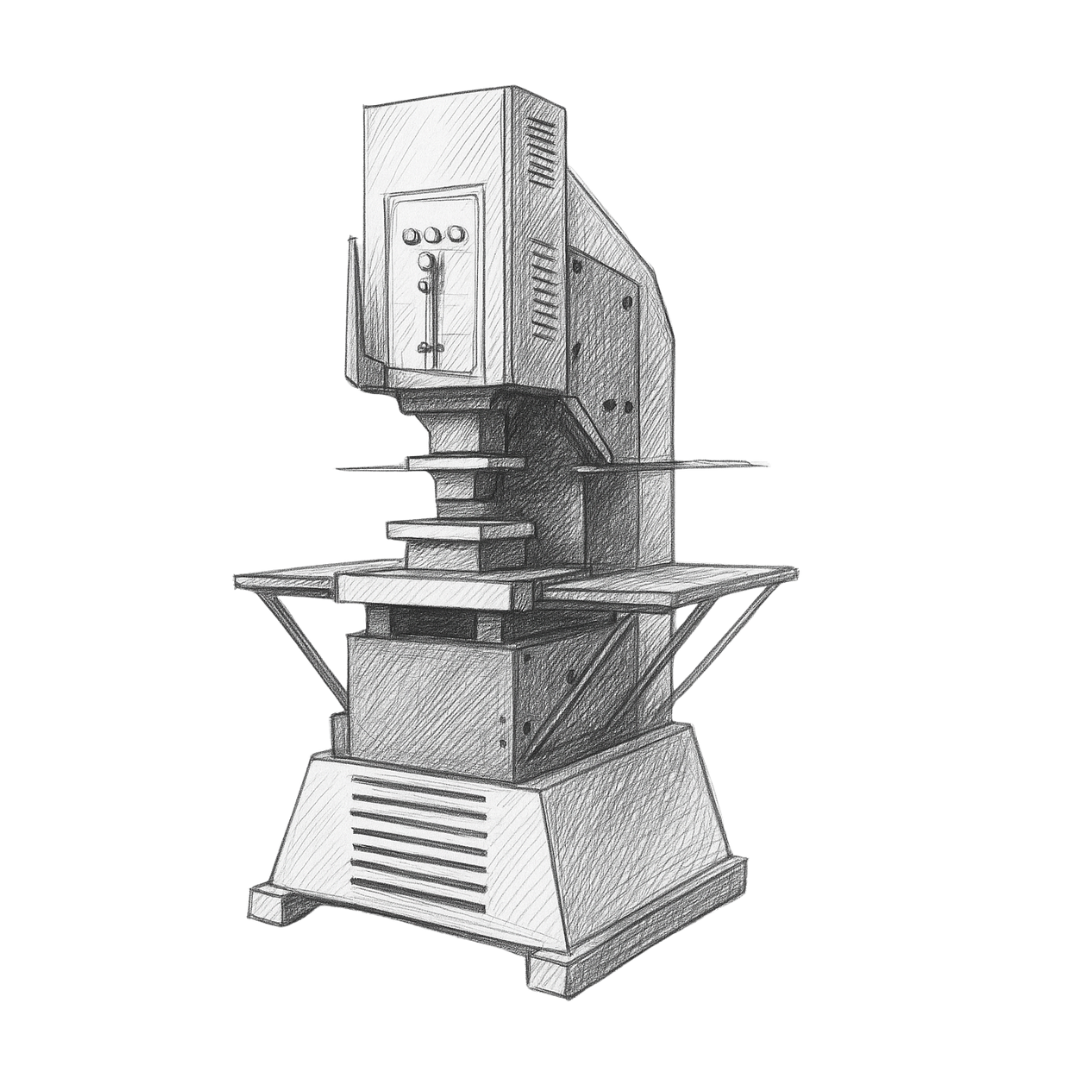

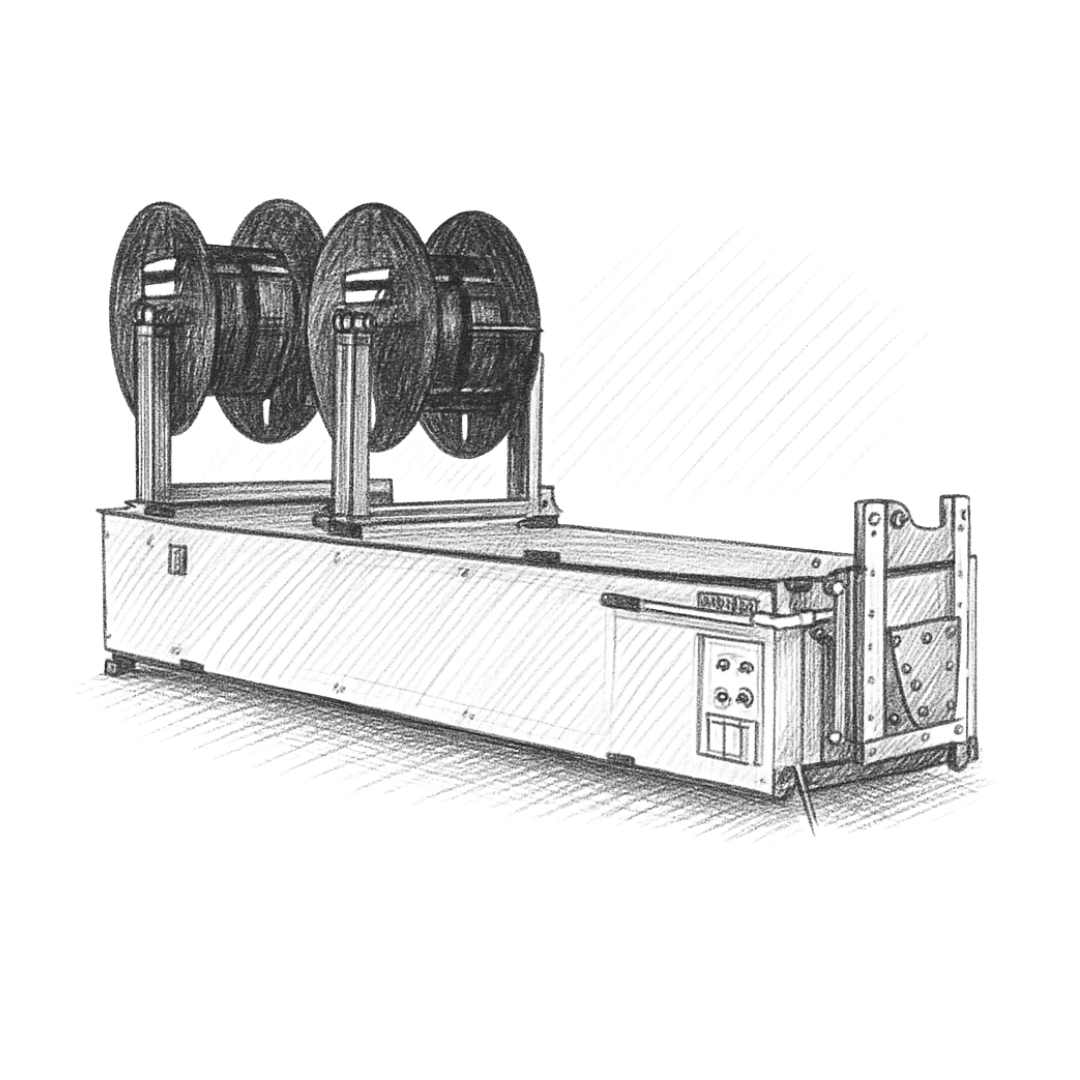

Manual segmented sheet metal bending machine Mazanek ZGRs 1250 L

SKU 5555-222-61

0 reviews

In stock

MAZANEK

0 uah.

Shipping

- Pickup (Self-pickup) For free

- New POST Up to 100 uan

- Meest up to 100

Payment

- Оплата при отриманні

- Готівкова оплата

- Оплата по рахунку

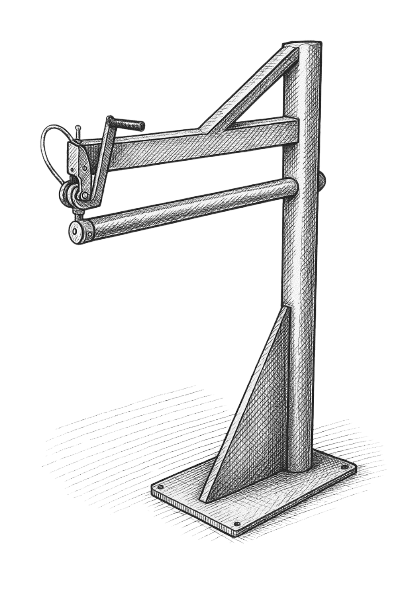

Segmented manual sheet metal bending machine ZGRs 1250 L by MAZANEK – a professional segmented machine for precise metal processing

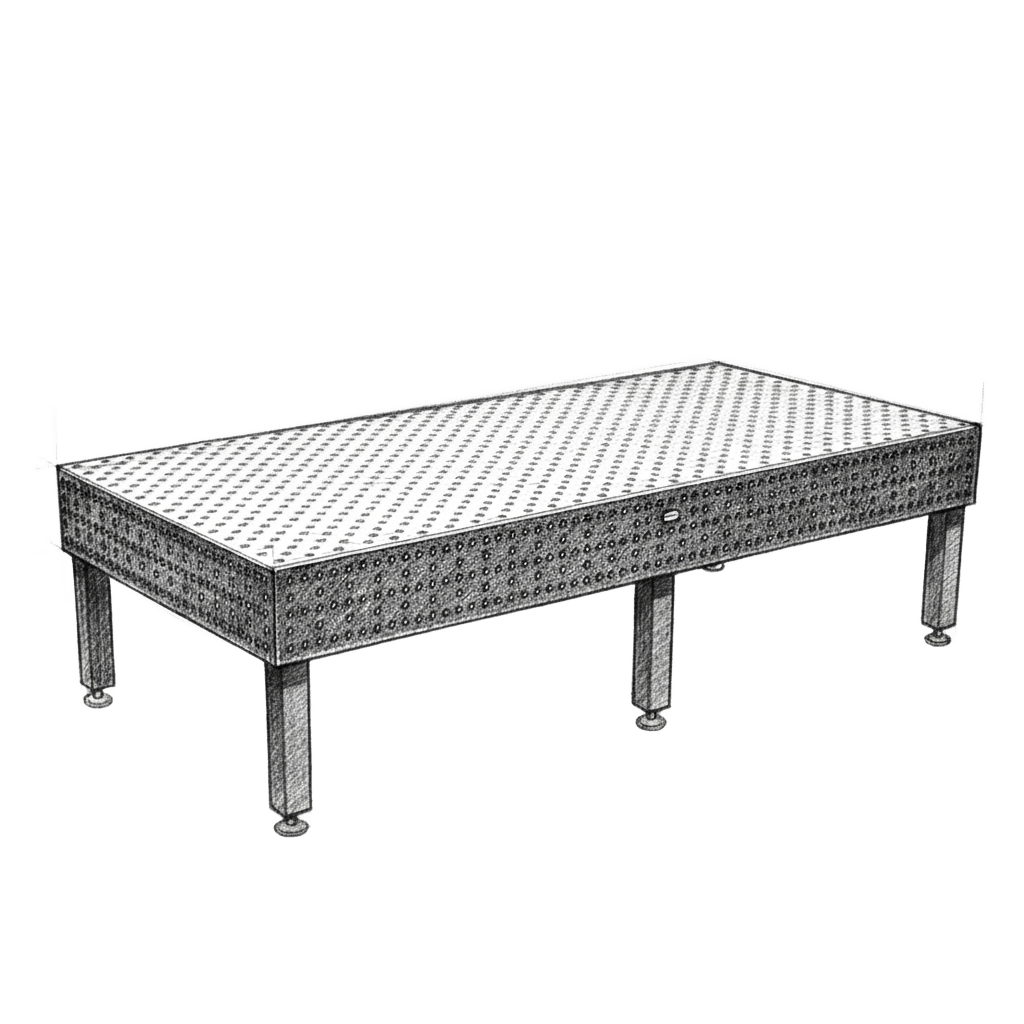

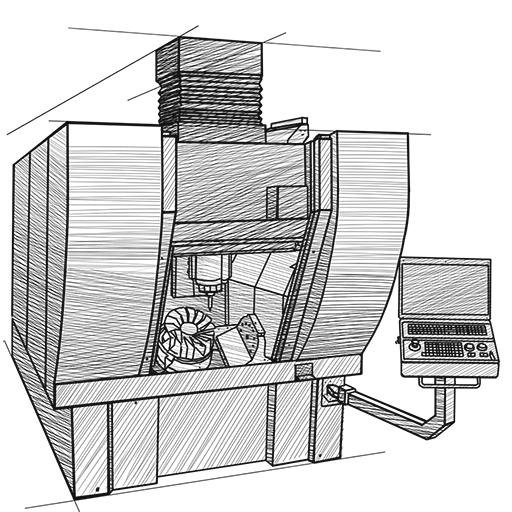

The ZGRs 1250 L segmented sheet metal bending machine is a modern and reliable manual segmented machine, designed by MAZANEK for professional bending of sheet metal up to 1.0 mm thick (with a material strength limit of Rm < 400 MPa).

This segmented bending machine is the ideal choice for workshops, construction companies, and industrial enterprises working with sheet metal. Thanks to its advanced segmented design, it allows for complex bending operations with maximum precision, ensuring durability, functionality, and ease of operation.

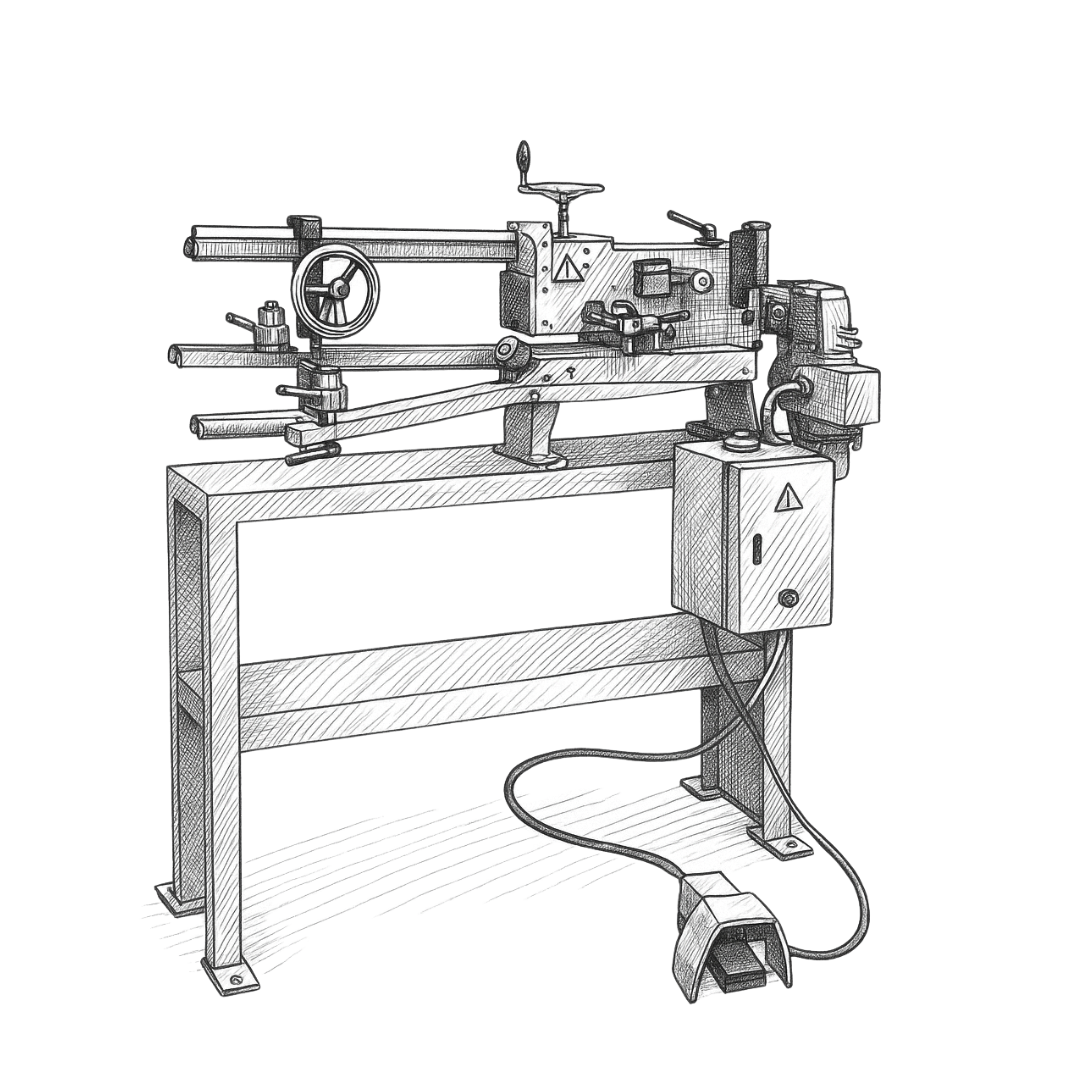

Key specifications of MAZANEK ZGRs 1250 L:

This segmented sheet metal bending machine features an ergonomic design and a wide range of adjustments, ensuring convenience in operation and versatility in processing different workpieces.

Bending beam length: 1300 mm – the perfect solution for handling large sheets, expanding bending possibilities.

Maximum sheet thickness: 1.0 mm (for Rm < 400 MPa) – suitable for steel, aluminum, and other medium-thickness materials.

Maximum bending angle: 0-130° – enables precise bends of varying complexity, essential for industrial applications.

Maximum beam opening: 100 mm (adjustable) – ensures convenient workpiece installation and removal, increasing productivity.

Segment working zone height: 80 mm.

Upper clamping beam segment height: 136 mm (working height: 80 mm).

Lower clamping beam segment height: 105 mm (working height: 80 mm).

Clearance between beams after segment removal: 84 mm.

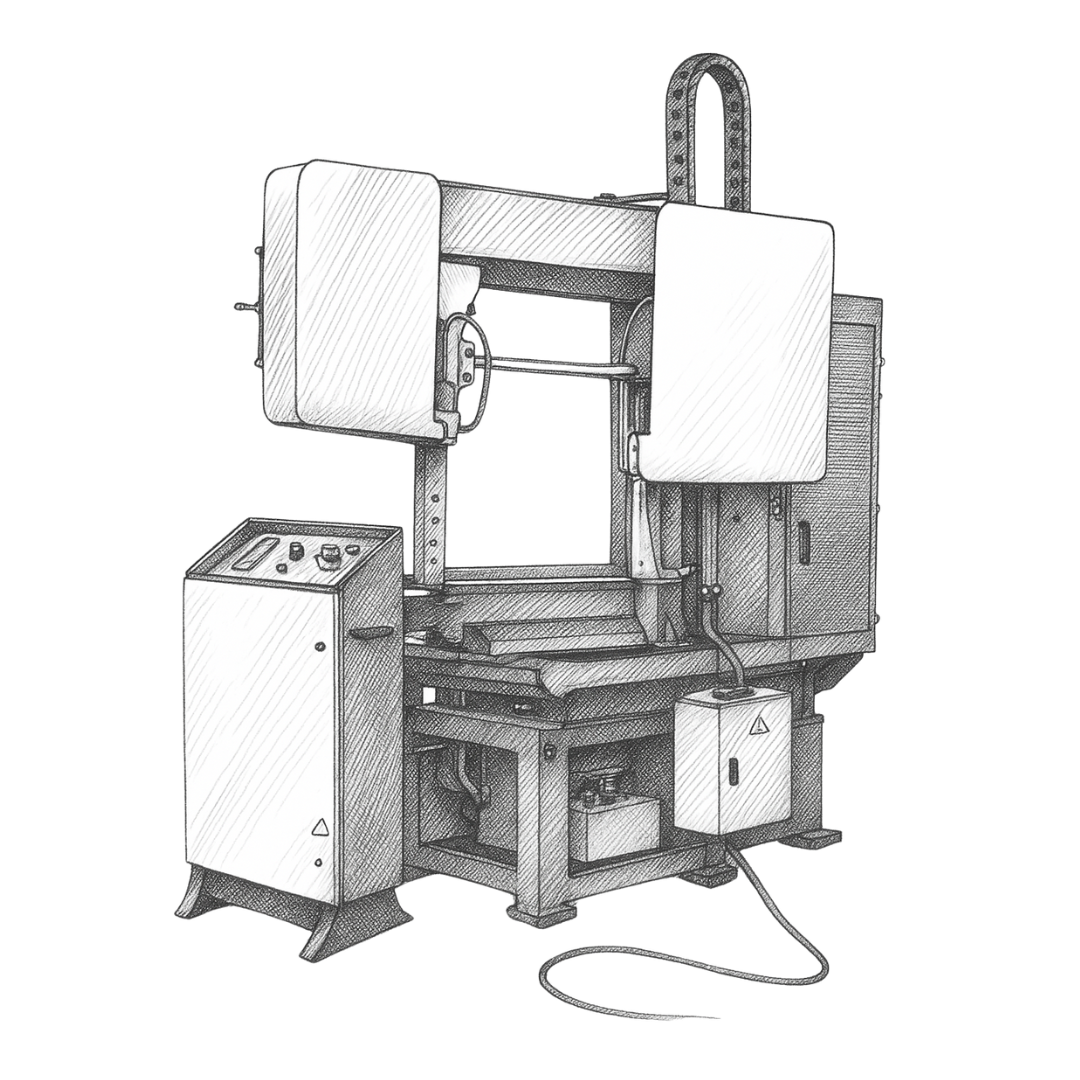

Design features and advantages of the ZGRs 1250 L segmented sheet metal bending machine:

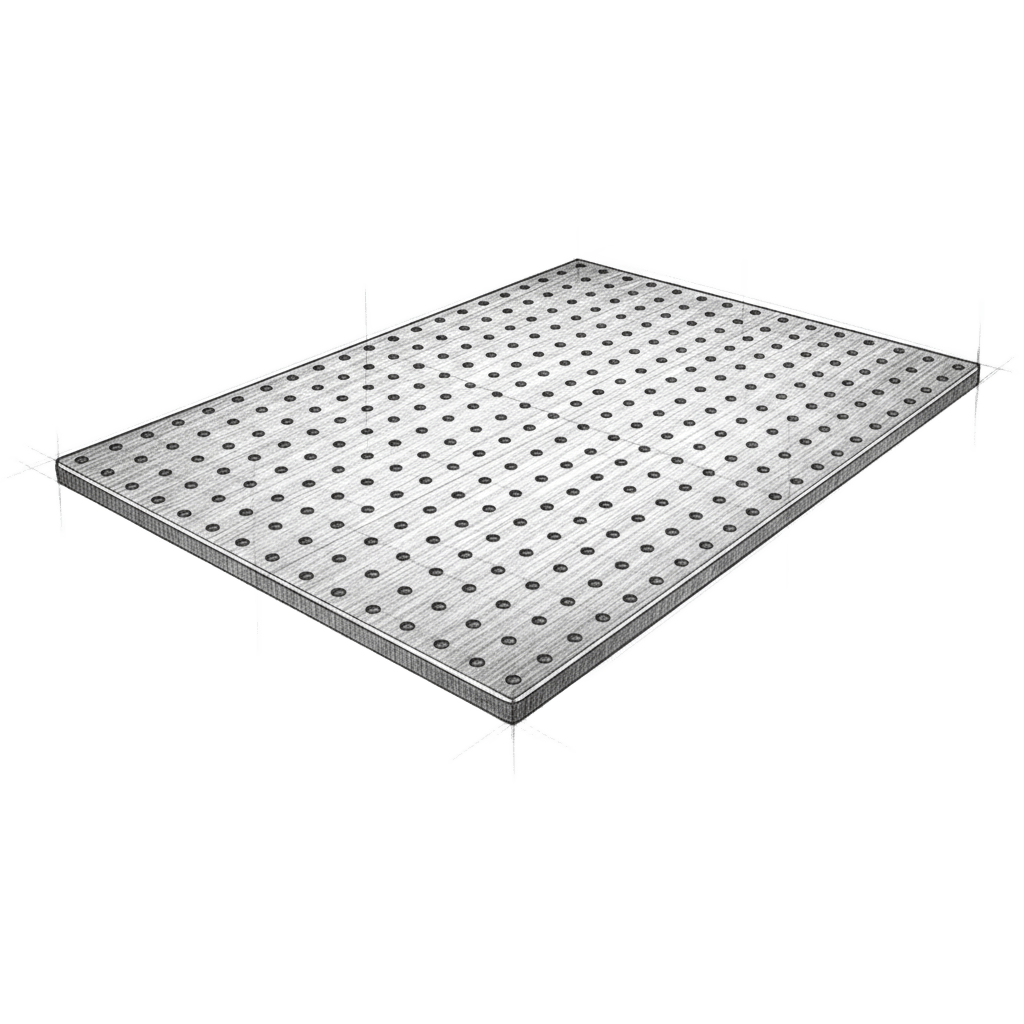

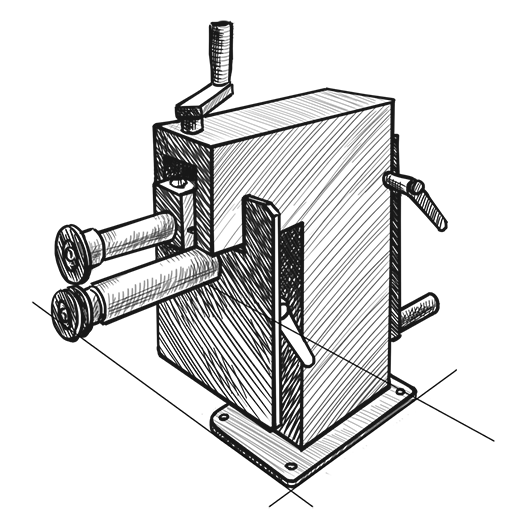

Interchangeable segments – installed on the upper and lower beams, made of high-strength steel, ensuring durability and stability.

Wide selection of segment sizes – allows installation of segments from 30 mm to 200 mm, enabling precise and complex bending.

Outer segments with beveled edges – for clean and highly precise bends.

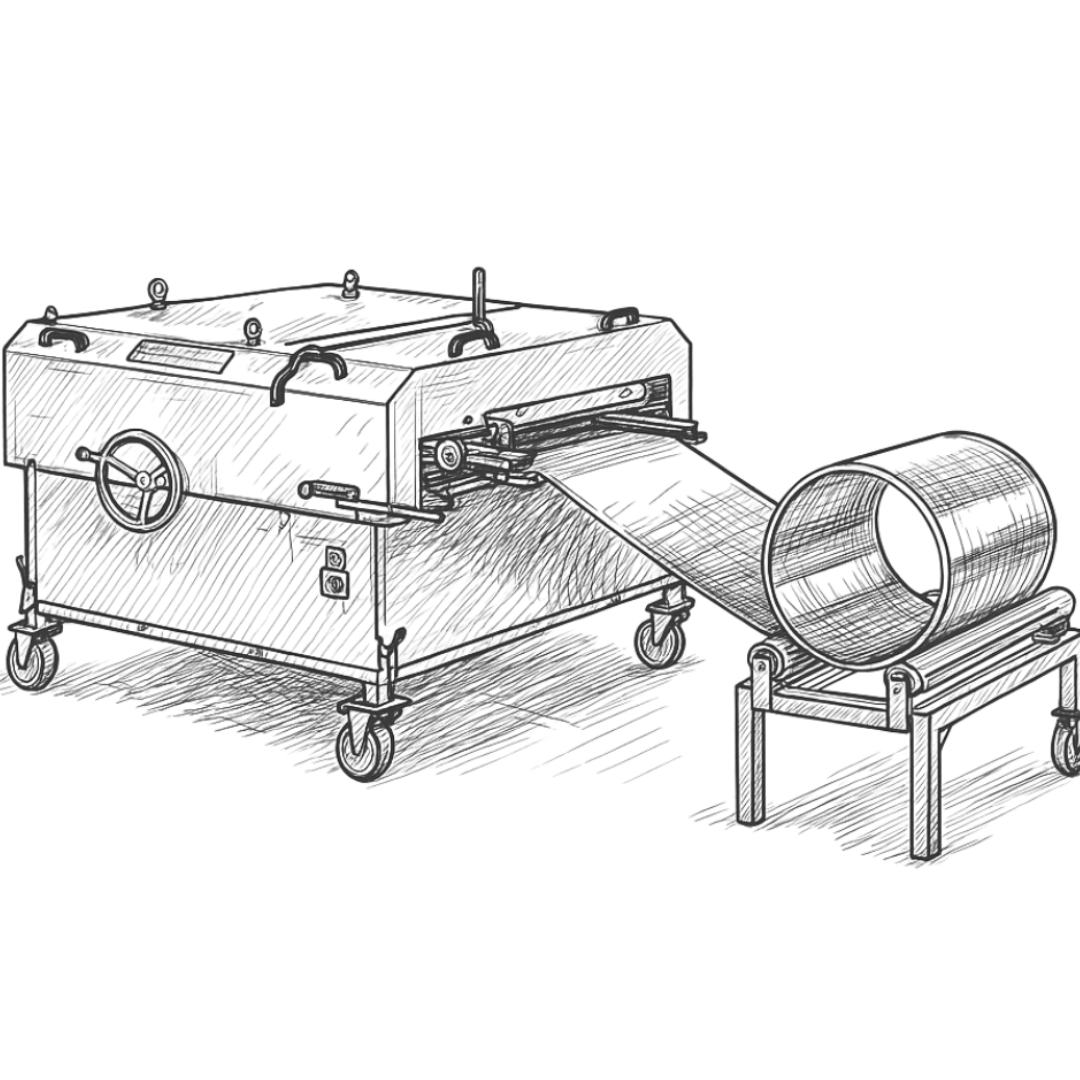

Easy operation – pressure is applied via a lever system, significantly simplifying use.

Foot-operated clamping system – allows the operator to hold the metal hands-free, increasing work efficiency.

Quick segment removal – simplifies reconfiguration for various types of tasks.

Rear supports for material holding – ensure stability when processing large sheet metal pieces.

Built-in storage box for segments – provides convenient organization of interchangeable components.

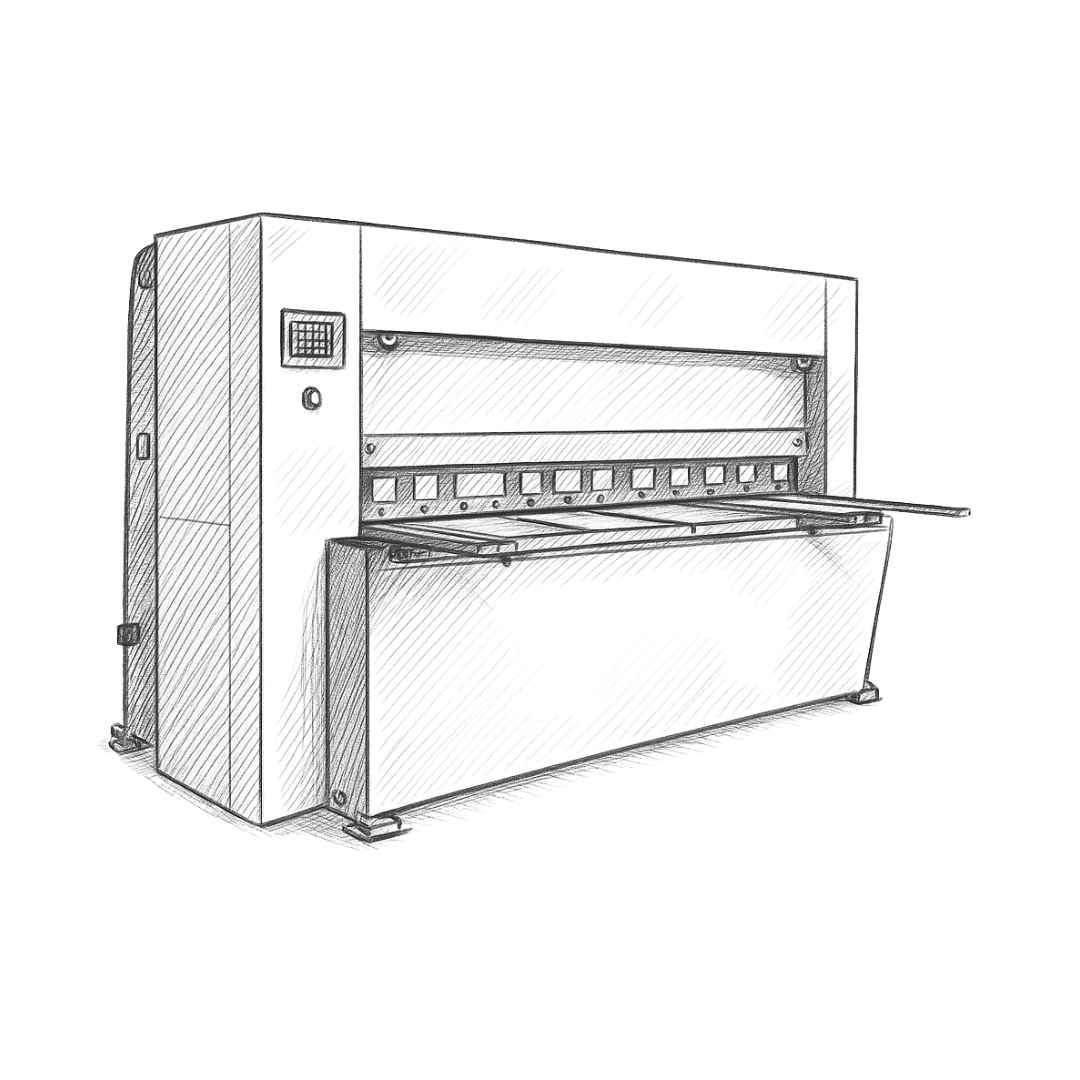

The segmented sheet metal bending machine includes a set of interchangeable segments, allowing work with sheets of various widths:

Minimum segment: 30 mm.

Maximum segment: 200 mm.

Available segment sizes: 30 mm, 40 mm, 50 mm, 60 mm, 70 mm, 100 mm, 150 mm.

Dimensions and weight of the MAZANEK ZGRs 1250 L segmented sheet metal bending machine:

Length: 1690 mm.

Width: 900 mm.

Height: 1080 mm.

Weight: 330 kg – the heavy-duty construction ensures stability and safety during metal bending.

Applications and benefits of MAZANEK ZGRs 1250 L:

This segmented sheet metal bending machine stands out for its versatility and ease of operation, allowing operators to quickly adjust the machine for different tasks.

Functionality – enables the formation of sheet metal at various angles, ensuring high bending precision.

Versatility – easily adapts to the needs of workshops, construction companies, and industrial enterprises.

Safety and convenience – the robust construction and intuitive controls ensure comfortable and safe operation, even in high-demand production environments.

Where to buy the MAZANEK ZGRs 1250 L segmented sheet metal bending machine?

If you are looking for a segmented sheet metal bending machine that offers high quality, reliability, and ease of use, then purchasing the ZGRs 1250 L from KVERB is an excellent choice.

This manual segmented sheet metal bending machine ensures high productivity and becomes an indispensable tool for professional sheet metal processing.

The ZGRs 1250 L segmented sheet metal bending machine is a modern and reliable manual segmented machine, designed by MAZANEK for professional bending of sheet metal up to 1.0 mm thick (with a material strength limit of Rm < 400 MPa).

This segmented bending machine is the ideal choice for workshops, construction companies, and industrial enterprises working with sheet metal. Thanks to its advanced segmented design, it allows for complex bending operations with maximum precision, ensuring durability, functionality, and ease of operation.

Key specifications of MAZANEK ZGRs 1250 L:

This segmented sheet metal bending machine features an ergonomic design and a wide range of adjustments, ensuring convenience in operation and versatility in processing different workpieces.

Bending beam length: 1300 mm – the perfect solution for handling large sheets, expanding bending possibilities.

Maximum sheet thickness: 1.0 mm (for Rm < 400 MPa) – suitable for steel, aluminum, and other medium-thickness materials.

Maximum bending angle: 0-130° – enables precise bends of varying complexity, essential for industrial applications.

Maximum beam opening: 100 mm (adjustable) – ensures convenient workpiece installation and removal, increasing productivity.

Segment working zone height: 80 mm.

Upper clamping beam segment height: 136 mm (working height: 80 mm).

Lower clamping beam segment height: 105 mm (working height: 80 mm).

Clearance between beams after segment removal: 84 mm.

Design features and advantages of the ZGRs 1250 L segmented sheet metal bending machine:

Interchangeable segments – installed on the upper and lower beams, made of high-strength steel, ensuring durability and stability.

Wide selection of segment sizes – allows installation of segments from 30 mm to 200 mm, enabling precise and complex bending.

Outer segments with beveled edges – for clean and highly precise bends.

Easy operation – pressure is applied via a lever system, significantly simplifying use.

Foot-operated clamping system – allows the operator to hold the metal hands-free, increasing work efficiency.

Quick segment removal – simplifies reconfiguration for various types of tasks.

Rear supports for material holding – ensure stability when processing large sheet metal pieces.

Built-in storage box for segments – provides convenient organization of interchangeable components.

The segmented sheet metal bending machine includes a set of interchangeable segments, allowing work with sheets of various widths:

Minimum segment: 30 mm.

Maximum segment: 200 mm.

Available segment sizes: 30 mm, 40 mm, 50 mm, 60 mm, 70 mm, 100 mm, 150 mm.

Dimensions and weight of the MAZANEK ZGRs 1250 L segmented sheet metal bending machine:

Length: 1690 mm.

Width: 900 mm.

Height: 1080 mm.

Weight: 330 kg – the heavy-duty construction ensures stability and safety during metal bending.

Applications and benefits of MAZANEK ZGRs 1250 L:

This segmented sheet metal bending machine stands out for its versatility and ease of operation, allowing operators to quickly adjust the machine for different tasks.

Functionality – enables the formation of sheet metal at various angles, ensuring high bending precision.

Versatility – easily adapts to the needs of workshops, construction companies, and industrial enterprises.

Safety and convenience – the robust construction and intuitive controls ensure comfortable and safe operation, even in high-demand production environments.

Where to buy the MAZANEK ZGRs 1250 L segmented sheet metal bending machine?

If you are looking for a segmented sheet metal bending machine that offers high quality, reliability, and ease of use, then purchasing the ZGRs 1250 L from KVERB is an excellent choice.

This manual segmented sheet metal bending machine ensures high productivity and becomes an indispensable tool for professional sheet metal processing.

Specifications Manual segmented sheet metal bending machine Mazanek ZGRs 1250 L

- Machine drive type Manual

- Thickness of processed sheet 1 mm

- Working length of the machine 1300 mm

- Maximum bend angle 130°

- Maximum beam opening 100°

- WEIGHT 330 kg

- LENGTH 1690 mm

- WIDTH 900 mm

- HEIGHT 1080 mm

Reviews

There are no reviews on this product yet, be the first

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21