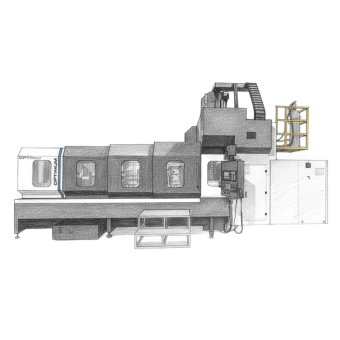

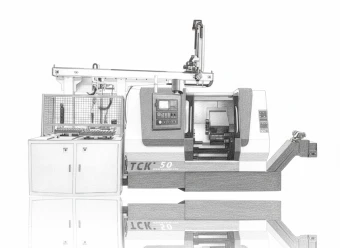

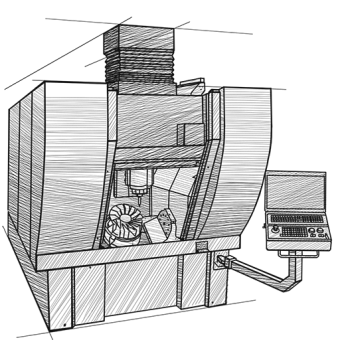

Horizontal CNC milling machining center XK6032

SKU 1920056

0 reviews

In stock

WEIDA

Shipping

- Pickup (Self-pickup) (For free)

- New POST (Up to 100 UAN)

- Meest (Up to 100 UAN)

Payment

- Payment upon receipt

- Cash payment

- Payment by bank details

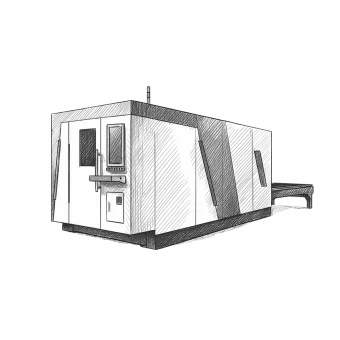

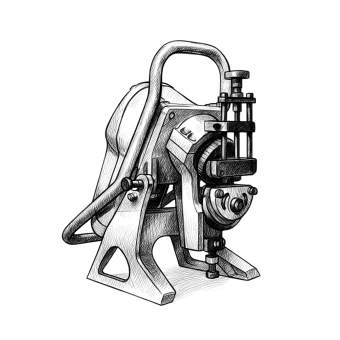

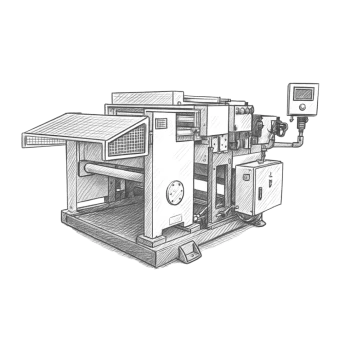

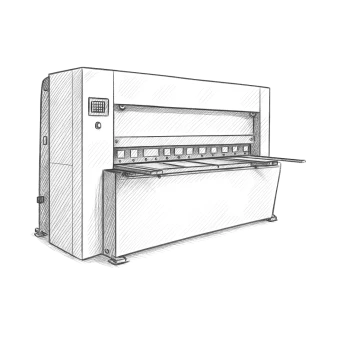

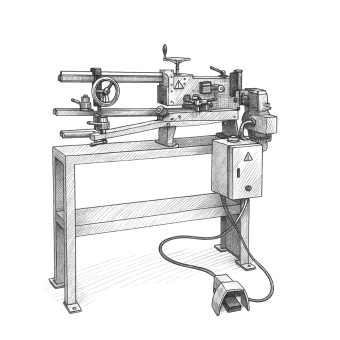

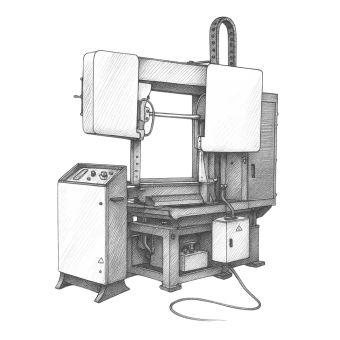

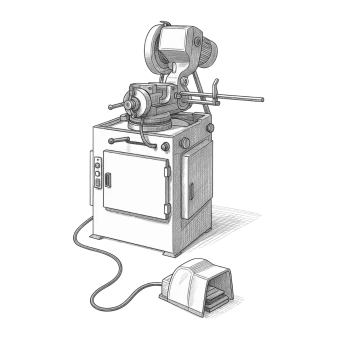

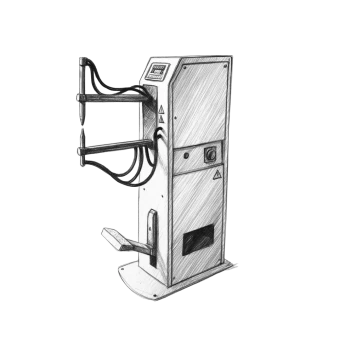

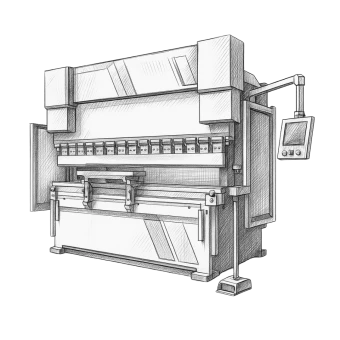

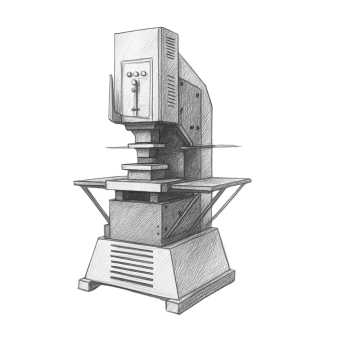

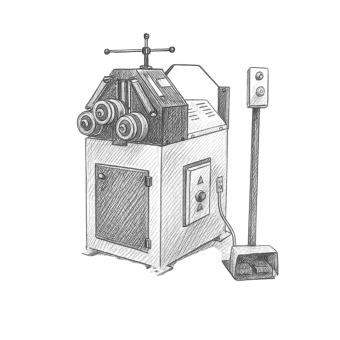

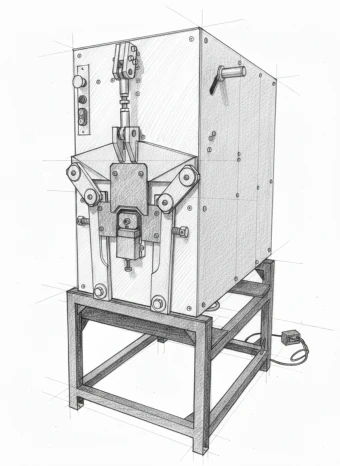

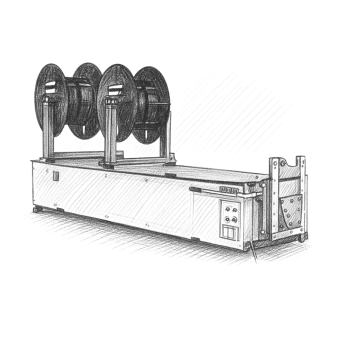

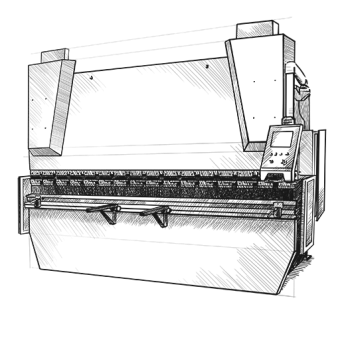

Horizontal CNC milling machining center XK6032 is high-precision equipment designed for machining large parts from various materials. It is equipped with a Guangshu 980M CNC system, providing ease of operation and high precision. For complex tasks, configurations with FANUC 0i MF or KND1000Ⅱ systems are available, allowing the equipment to be adapted to specific production needs.

XK6032 is used for precise milling and machining of metal workpieces. It is ideal for mechanical engineering, the automotive industry, and metal structure production, where reliability and high performance are required.

This machining center is an excellent choice for medium and large-scale enterprises engaged in serial production of precise metal products. It is used for manufacturing machine components, automotive parts, and complex metal structures.

Technical specifications:

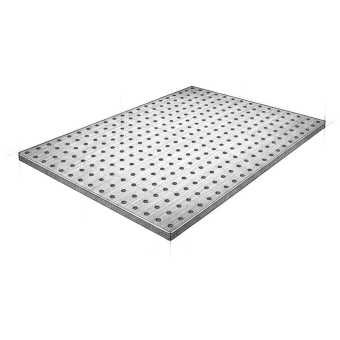

Table travel (X, Y, Z): 800×350×280 mm.

Table size: 1320×320 mm.

Maximum table load: 320 kg.

Distance from spindle axis to table: 20–370 mm.

Traverse speed (X/Y/Z axes): 6000/3000/6000 mm/min.

Spindle taper: ISO50 (7:24).

Spindle speed: 30–1500 rpm.

Maximum spindle torque: 1000 Nm.

Spindle motor power: 7.5 kW.

Advantages and features:

The powerful spindle with a torque of 1000 Nm ensures stability when machining complex materials.

The Guangshu 980M CNC system and the option to select other configurations guarantee machining precision.

High feed rates reduce the time required for machining large workpieces.

The robust construction weighing 2800 kg ensures reliability and accuracy under heavy loads.

Easy access to control elements simplifies setup and maintenance.

You can purchase the horizontal CNC milling machining center XK6032 from the company KVERB.

We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the horizontal CNC milling machining center XK6032.

XK6032 is used for precise milling and machining of metal workpieces. It is ideal for mechanical engineering, the automotive industry, and metal structure production, where reliability and high performance are required.

This machining center is an excellent choice for medium and large-scale enterprises engaged in serial production of precise metal products. It is used for manufacturing machine components, automotive parts, and complex metal structures.

Technical specifications:

Table travel (X, Y, Z): 800×350×280 mm.

Table size: 1320×320 mm.

Maximum table load: 320 kg.

Distance from spindle axis to table: 20–370 mm.

Traverse speed (X/Y/Z axes): 6000/3000/6000 mm/min.

Spindle taper: ISO50 (7:24).

Spindle speed: 30–1500 rpm.

Maximum spindle torque: 1000 Nm.

Spindle motor power: 7.5 kW.

Advantages and features:

The powerful spindle with a torque of 1000 Nm ensures stability when machining complex materials.

The Guangshu 980M CNC system and the option to select other configurations guarantee machining precision.

High feed rates reduce the time required for machining large workpieces.

The robust construction weighing 2800 kg ensures reliability and accuracy under heavy loads.

Easy access to control elements simplifies setup and maintenance.

You can purchase the horizontal CNC milling machining center XK6032 from the company KVERB.

We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the horizontal CNC milling machining center XK6032.

Specifications Horizontal CNC milling machining center XK6032

- Number of axes 3

- WEIGHT 2800

- LENGTH 1929

- WIDTH 2055

- HEIGHT 1960

Reviews

There are no reviews on this product yet, be the first

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21