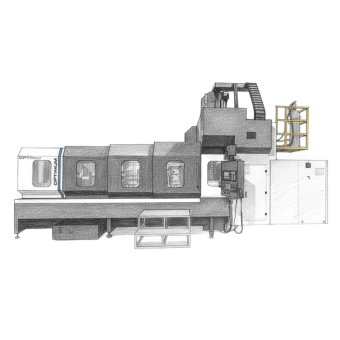

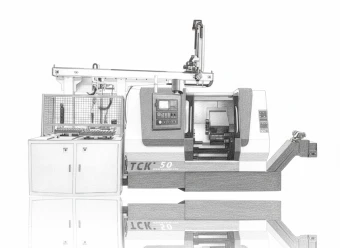

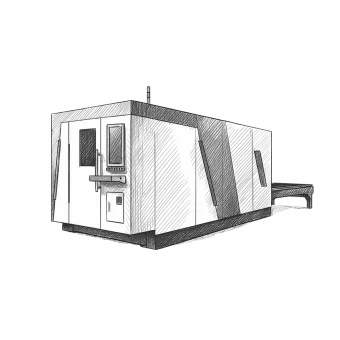

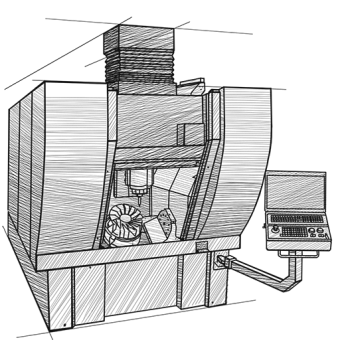

CNC milling machining center Equiptop ETM-510

SKU 1920001

0 reviews

In stock

EQUIPTOP

Shipping

- Pickup (Self-pickup) (For free)

- New POST (Up to 100 UAN)

- Meest (Up to 100 UAN)

Payment

- Payment upon receipt

- Cash payment

- Payment by bank details

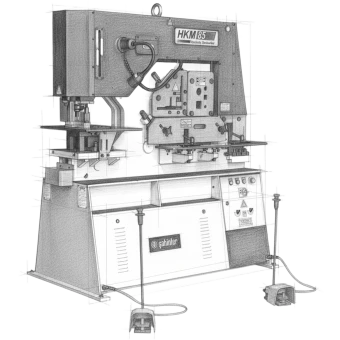

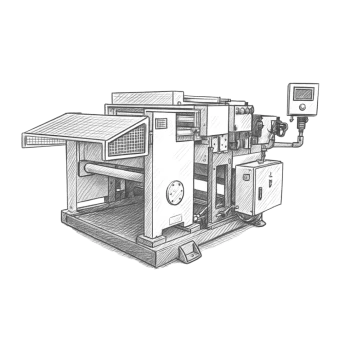

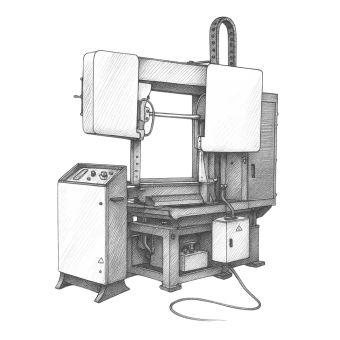

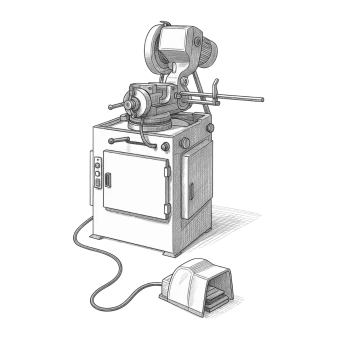

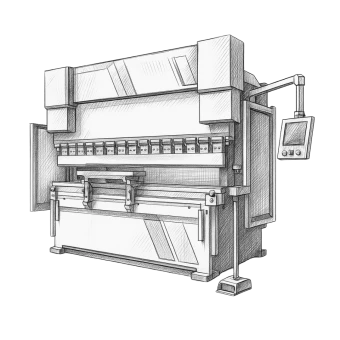

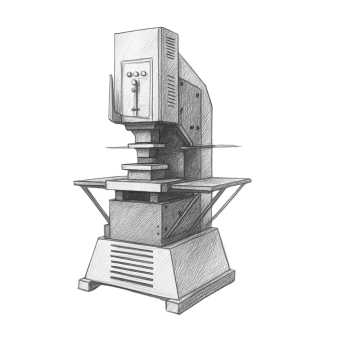

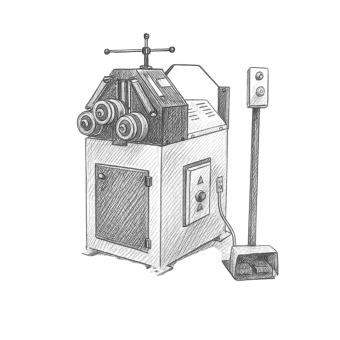

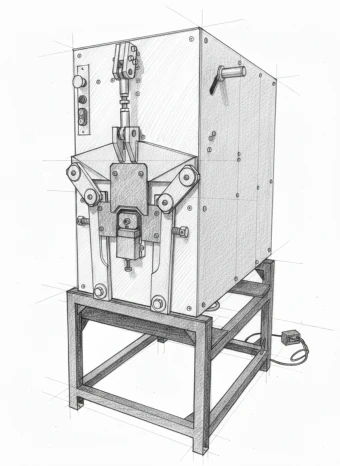

CNC milling machining center Equiptop ETM-510 is designed for high-precision metal processing operations. The CNC system ensures stability and automation, making it suitable for both serial and custom production.

The model is available in two versions: ETM-510 and ETM-510APC. These versions share similar features but differ in certain technical parameters. Large working travels allow for the processing of large parts with precision. The software and high-quality components ensure reliability and productivity.

The machine is suitable for processing steel, aluminum, cast iron alloys, and other materials. It performs operations such as surface machining, drilling, cutting, and threading. The machining center is used for manufacturing complex parts for the automotive, aviation, and energy industries, as well as for prototyping.

Technical specifications:

Distance from spindle to table: 200–650 mm

Spindle speed: 8000 rpm (optional 10000/12000/15000)

Tool type: manual type 20T

Maximum tool diameter: 65 mm

Maximum tool weight: 3 kg

Tool shank type: BT30

Motor: 3.7 kW

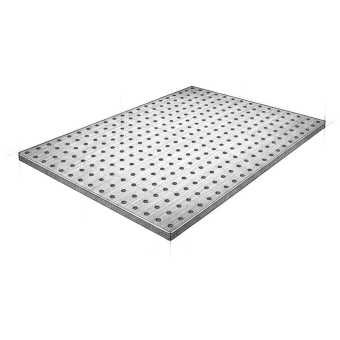

Table size: 600x360 mm

Maximum table load capacity: 250 kg

Travel speed along X/Y/Z axes: 48 m/min (linear guides)

Working feed rate: 1–1000 mm/min

Controller: M70/M80 or Oi-MF

Power consumption: 10 KVA

Air consumption: 6 kg/cm²

Advantages and features:

High precision is achieved through the use of laser technology for axis travel compensation.

Automation is provided by the tool change system, reducing setup time and increasing productivity.

Feed rate and spindle speed allow for processing a wide range of materials.

Innovative cleaning and chip removal mechanisms improve quality and reduce downtime.

Durability and reliability are ensured by high-quality materials and components.

Flexible configuration allows the machine to be adapted for various tasks, including spindle speed selection and cooling system adjustments.

You can purchase the CNC milling machining center Equiptop ETM-510 from the company KVERB. We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the CNC milling machining center Equiptop ETM-510.

The model is available in two versions: ETM-510 and ETM-510APC. These versions share similar features but differ in certain technical parameters. Large working travels allow for the processing of large parts with precision. The software and high-quality components ensure reliability and productivity.

The machine is suitable for processing steel, aluminum, cast iron alloys, and other materials. It performs operations such as surface machining, drilling, cutting, and threading. The machining center is used for manufacturing complex parts for the automotive, aviation, and energy industries, as well as for prototyping.

Technical specifications:

Distance from spindle to table: 200–650 mm

Spindle speed: 8000 rpm (optional 10000/12000/15000)

Tool type: manual type 20T

Maximum tool diameter: 65 mm

Maximum tool weight: 3 kg

Tool shank type: BT30

Motor: 3.7 kW

Table size: 600x360 mm

Maximum table load capacity: 250 kg

Travel speed along X/Y/Z axes: 48 m/min (linear guides)

Working feed rate: 1–1000 mm/min

Controller: M70/M80 or Oi-MF

Power consumption: 10 KVA

Air consumption: 6 kg/cm²

Advantages and features:

High precision is achieved through the use of laser technology for axis travel compensation.

Automation is provided by the tool change system, reducing setup time and increasing productivity.

Feed rate and spindle speed allow for processing a wide range of materials.

Innovative cleaning and chip removal mechanisms improve quality and reduce downtime.

Durability and reliability are ensured by high-quality materials and components.

Flexible configuration allows the machine to be adapted for various tasks, including spindle speed selection and cooling system adjustments.

You can purchase the CNC milling machining center Equiptop ETM-510 from the company KVERB. We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the CNC milling machining center Equiptop ETM-510.

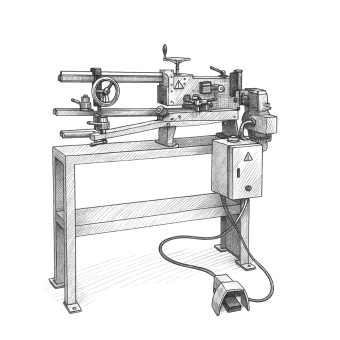

Specifications CNC milling machining center Equiptop ETM-510

- Table size 600 × 360 mm

- Spindle speed 8000 RPM

- Cutting feed rate 1-1000 mm/min

- Max. Tool Diameter 65

- Max. Tool Length 200

- Max. Tool Weight 3

- Max. Travel For X Axis 510

- Max. Travel For Y Axis 400

- Max. Travel For Z Axis 450

- Spindle Nose To Table 200-650 mm

- Max. Table Capacity 250

- Spindle Motor Power (Mitsubishi/Fanuc) 3.7/7.5 kW

- Number of axes 3

- WEIGHT 2800

Reviews

There are no reviews on this product yet, be the first

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21