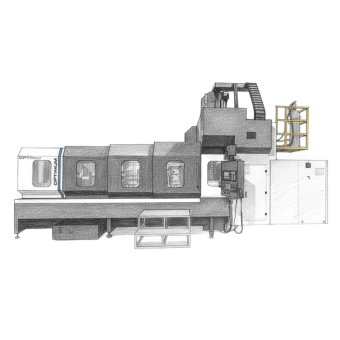

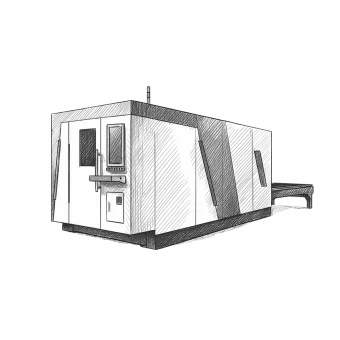

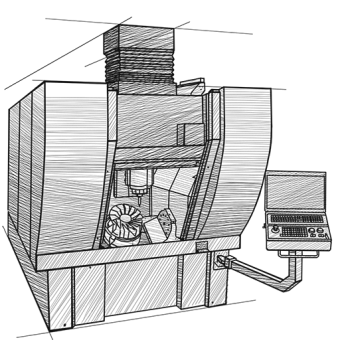

CNC milling machining center HMC630e

SKU 1920046

0 reviews

In stock

WEIDA

Shipping

- Pickup (Self-pickup) (For free)

- New POST (Up to 100 UAN)

- Meest (Up to 100 UAN)

Payment

- Payment upon receipt

- Cash payment

- Payment by bank details

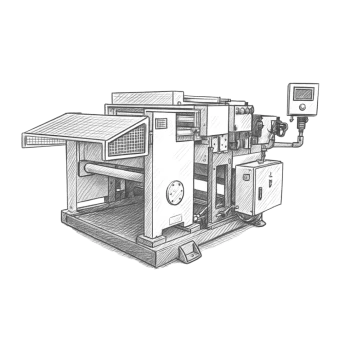

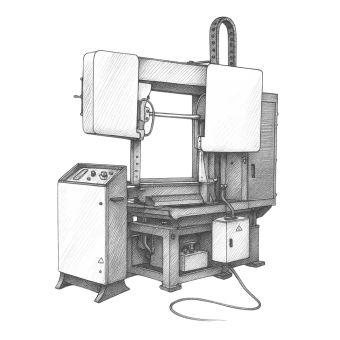

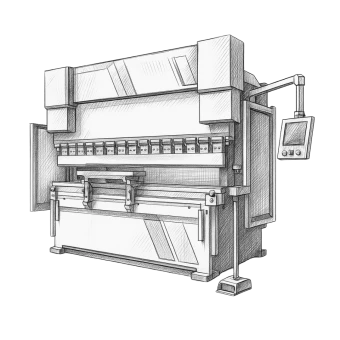

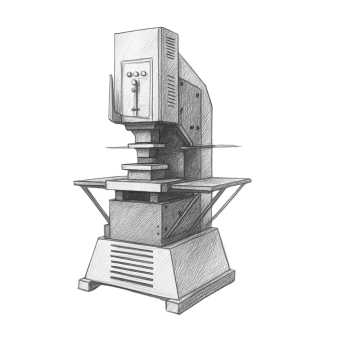

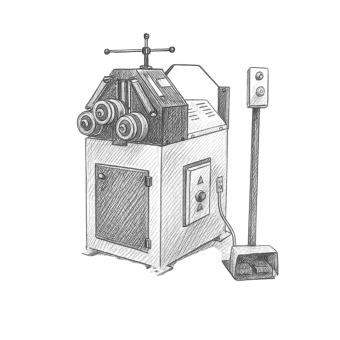

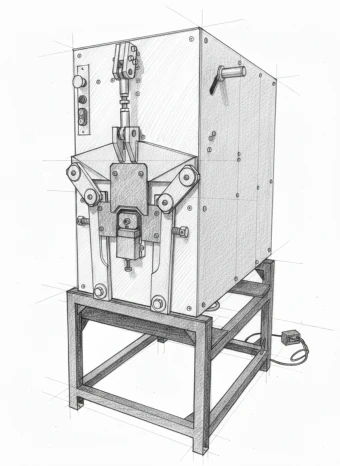

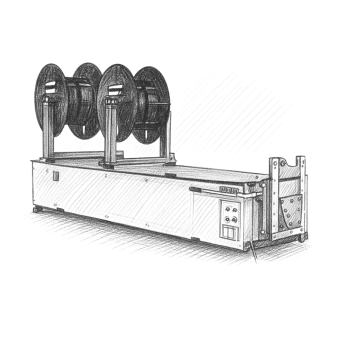

CNC milling machining center HMC630e is modern next-generation equipment designed for efficient mechanical processing of various metal workpieces. Thanks to its rigid construction, high speed, and powerful spindle, the machining center ensures operational stability and high machining quality.

HMC630e is designed for performing complex milling, drilling, and boring operations. Its high rigidity and precision make it ideal for machining box-type parts and complex surfaces used in heavy mechanical engineering.

Suitable for the following industries:

Mechanical engineering – production of structural parts and mechanism components.

Automotive industry – manufacturing engines, gearboxes, and chassis.

Shipbuilding – machining large structural elements.

Aerospace industry – production of high-precision parts.

Agro-industrial sector – manufacturing agricultural machinery.

Technical specifications:

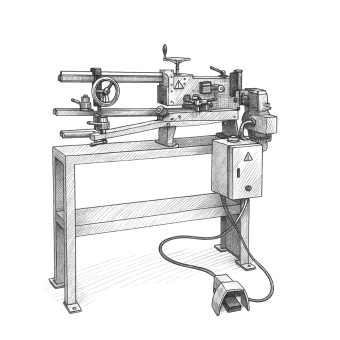

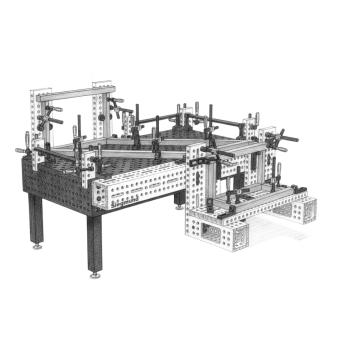

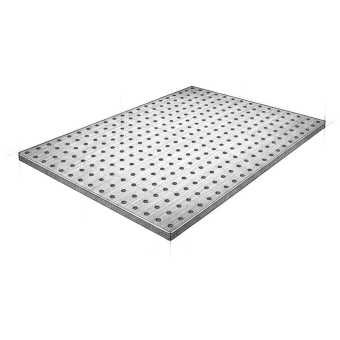

Worktable size: 630×630 mm

Maximum table load capacity: 1200 kg

Spindle speed: 30–3000 rpm

Tool type: BT50

Traverse speed along X/Y/Z axes: 32 m/min

Controller: FANUC 0i MF or Siemens 828D

Power consumption: 15 kW

Weight: 22000 kg

Advantages and features:

The T-shaped design ensures stability when machining heavy parts.

High spindle speed allows precise machining.

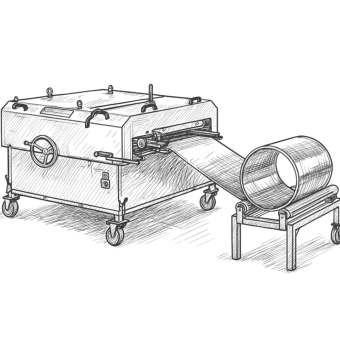

Automatic table changing reduces downtime.

The cooling system extends spindle service life.

Precise positioning guarantees consistent machining quality.

High load capacity enables working with heavy workpieces.

You can purchase the CNC milling machining center HMC630e from the company KVERB.

We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the CNC milling machining center HMC630e.

HMC630e is designed for performing complex milling, drilling, and boring operations. Its high rigidity and precision make it ideal for machining box-type parts and complex surfaces used in heavy mechanical engineering.

Suitable for the following industries:

Mechanical engineering – production of structural parts and mechanism components.

Automotive industry – manufacturing engines, gearboxes, and chassis.

Shipbuilding – machining large structural elements.

Aerospace industry – production of high-precision parts.

Agro-industrial sector – manufacturing agricultural machinery.

Technical specifications:

Worktable size: 630×630 mm

Maximum table load capacity: 1200 kg

Spindle speed: 30–3000 rpm

Tool type: BT50

Traverse speed along X/Y/Z axes: 32 m/min

Controller: FANUC 0i MF or Siemens 828D

Power consumption: 15 kW

Weight: 22000 kg

Advantages and features:

The T-shaped design ensures stability when machining heavy parts.

High spindle speed allows precise machining.

Automatic table changing reduces downtime.

The cooling system extends spindle service life.

Precise positioning guarantees consistent machining quality.

High load capacity enables working with heavy workpieces.

You can purchase the CNC milling machining center HMC630e from the company KVERB.

We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the CNC milling machining center HMC630e.

Specifications CNC milling machining center HMC630e

- Table size 630 × 630 mm

- Spindle speed 30-6000 RPM

- Max. Tool Weight 25 kg

- Max. Travel For X Axis 1000

- Max. Travel For Y Axis 800

- Max. Travel For Z Axis 800

- Max. Table Capacity 1200

- Spindle Motor Power 15/18.5 kW

- Number of axes 3

- WEIGHT 22000

Reviews

There are no reviews on this product yet, be the first

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21