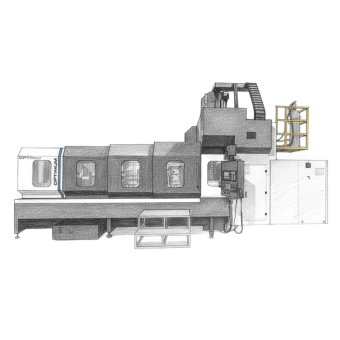

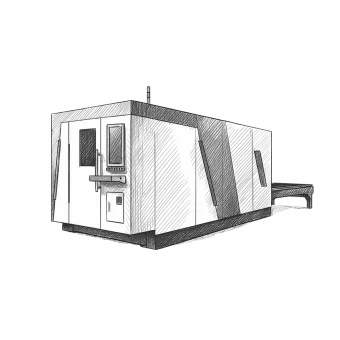

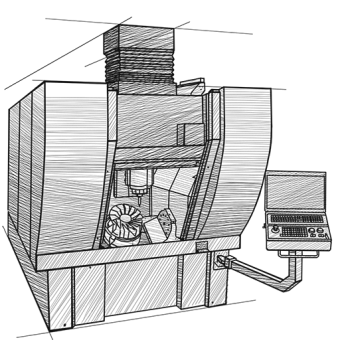

CNC milling machining center GMC1520

SKU 1920013

0 reviews

In stock

WEIDA

Shipping

- Pickup (Self-pickup) (For free)

- New POST (Up to 100 UAN)

- Meest (Up to 100 UAN)

Payment

- Payment upon receipt

- Cash payment

- Payment by bank details

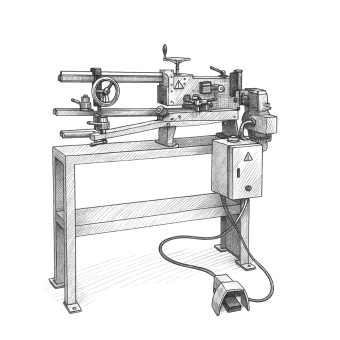

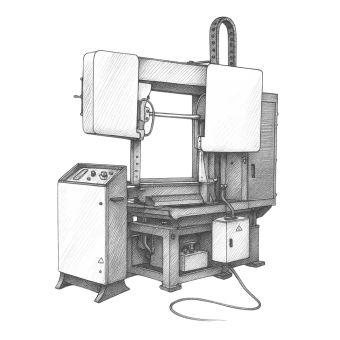

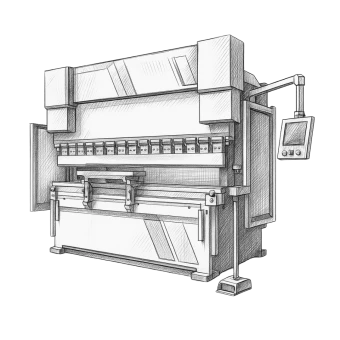

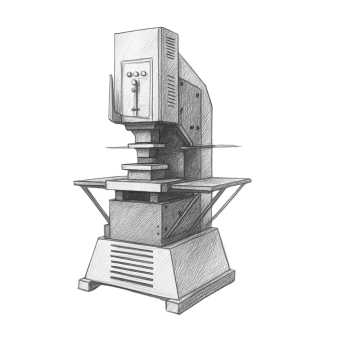

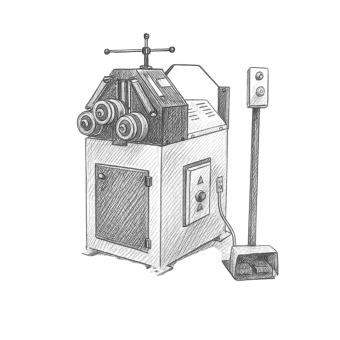

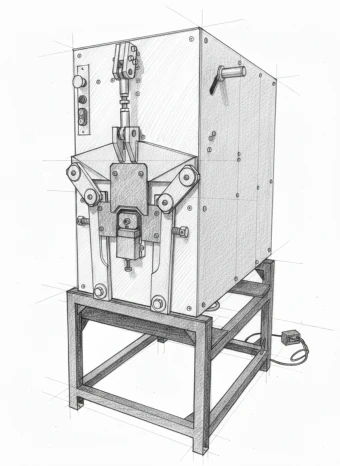

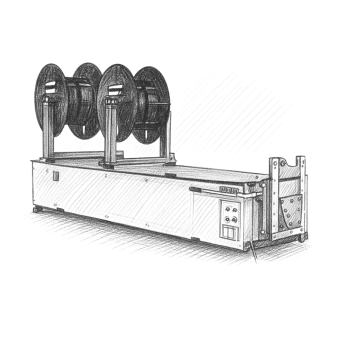

CNC milling machining center GMC1520 is designed for machining metal and composite materials with high precision. The machine meets modern industrial production requirements, ensuring rigidity, performance, and accuracy for complex operations.

The GMC1520 milling center is ideal for machining complex-shaped parts requiring high surface quality. It is used in the aerospace, automotive, energy, and other high-tech industries. It is suitable for manufacturing molds, casting forms, dies, and complex workpieces.

This machine is an excellent choice for enterprises engaged in the production of:

Molds and casting forms.

Dies and complex workpieces.

Parts for the aerospace and automotive industries.

Components for the energy sector.

Technical specifications GMC1520:

Distance from spindle to table: 150–950 mm.

Spindle speed: 30–3200 rpm.

Tool type: BT50.

Maximum tool weight: 8 kg.

Motor: 15/18.5 kW.

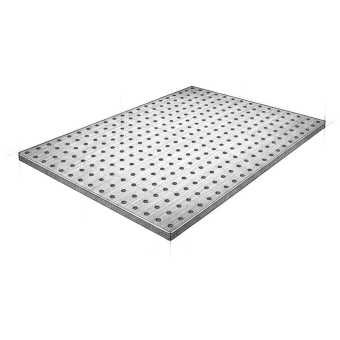

Table size: 2000×1500 mm.

Maximum table load capacity: 6000 kg.

Traverse speed along X/Y/Z axes: 15000/15000/12000 mm/min.

Feed rate: 1–10000/1–10000/1–8000 mm/min.

Controller: JIS ±0.005/300 mm.

Advantages and features GMC1520:

The modern CNC system simplifies programming and machining management.

Automatic tool change reduces downtime and increases productivity.

The robust construction ensures durability and resistance to loads.

Versatile application allows machining a wide range of materials, including metals, alloys, and composites.

You can purchase the CNC milling machining center GMC1520 from the company KVERB.

We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the CNC milling machining center GMC1520.

The GMC1520 milling center is ideal for machining complex-shaped parts requiring high surface quality. It is used in the aerospace, automotive, energy, and other high-tech industries. It is suitable for manufacturing molds, casting forms, dies, and complex workpieces.

This machine is an excellent choice for enterprises engaged in the production of:

Molds and casting forms.

Dies and complex workpieces.

Parts for the aerospace and automotive industries.

Components for the energy sector.

Technical specifications GMC1520:

Distance from spindle to table: 150–950 mm.

Spindle speed: 30–3200 rpm.

Tool type: BT50.

Maximum tool weight: 8 kg.

Motor: 15/18.5 kW.

Table size: 2000×1500 mm.

Maximum table load capacity: 6000 kg.

Traverse speed along X/Y/Z axes: 15000/15000/12000 mm/min.

Feed rate: 1–10000/1–10000/1–8000 mm/min.

Controller: JIS ±0.005/300 mm.

Advantages and features GMC1520:

The modern CNC system simplifies programming and machining management.

Automatic tool change reduces downtime and increases productivity.

The robust construction ensures durability and resistance to loads.

Versatile application allows machining a wide range of materials, including metals, alloys, and composites.

You can purchase the CNC milling machining center GMC1520 from the company KVERB.

We offer:

Delivery across Ukraine.

Official warranty and technical support.

Professional consultation to select the equipment that suits your needs.

Contact our managers right now to get the best offer on the CNC milling machining center GMC1520.

Specifications CNC milling machining center GMC1520

- Table size 2000 × 1500 mm

- Spindle speed 3000 RPM

- Cutting feed rate (X/Y/Z) 1-10000/1-10000/1-6000 mm/min

- Max. Travel For X Axis 2200

- Max. Travel For Y Axis 2000

- Max. Travel For Z Axis 800

- Spindle Nose To Table 165-965 mm

- Max. Table Capacity 6000

- Spindle Motor Power 15/18.5 kW

- Number of axes 3

- WEIGHT 23000

- LENGTH 7400

- WIDTH 4900

- HEIGHT 4850

Reviews

There are no reviews on this product yet, be the first

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21