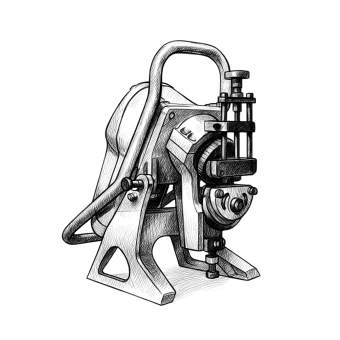

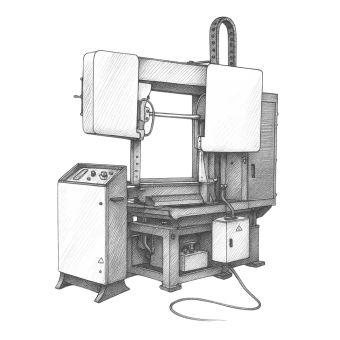

Flanging Machine Prinzing FME 4-1200

SKU 0506-666-602

0 reviews

In stock

PRINZING

Shipping

- Pickup (Self-pickup) (For free)

- New POST (Up to 100 UAN)

- Meest (Up to 100 UAN)

Payment

- Payment upon receipt

- Cash payment

- Payment by bank details

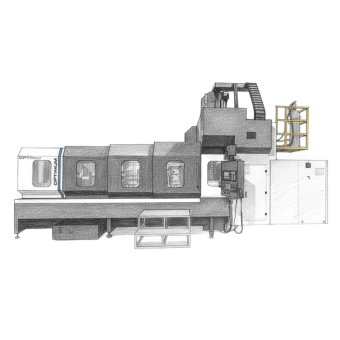

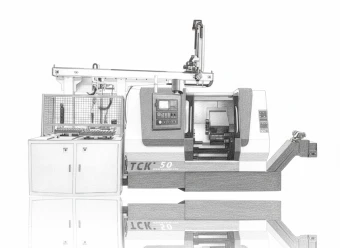

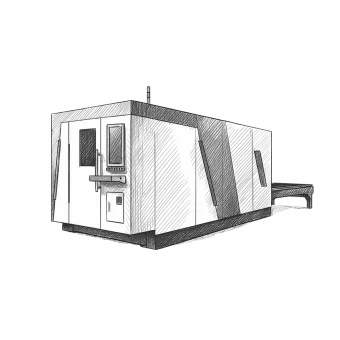

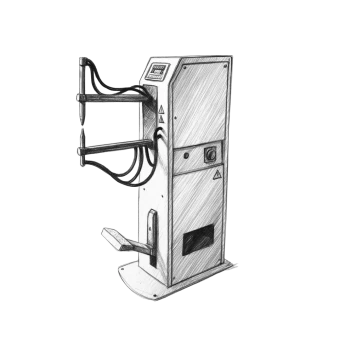

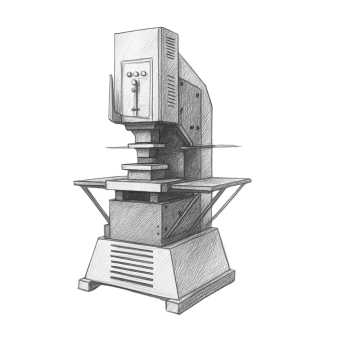

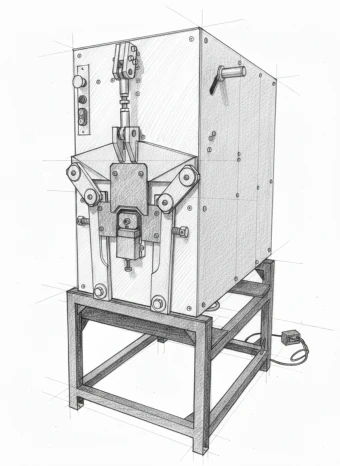

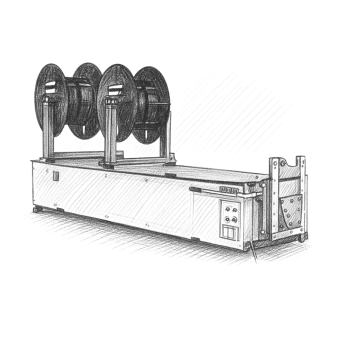

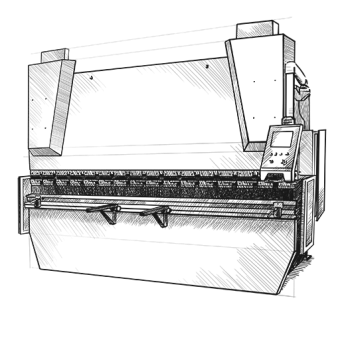

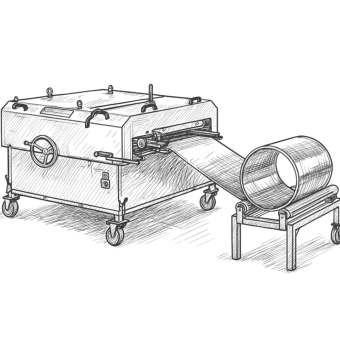

Flanging Machine Prinzing FME 4-1200 is designed for flange processing with precise control over processes and the ability to automate settings. It handles pipes with diameters up to 1200 mm and sheet thicknesses up to 4 mm, ensuring high accuracy and stability in production processes.

Prinzing FME 4-1200 is used in the metallurgical, oil, gas, and chemical industries, providing high-quality flange manufacturing at all stages of production.

This flanging machine is ideal for companies involved in pipeline production, metal structure processing, and manufacturing pipe connections and flanges for industrial systems. Its capabilities allow for flange production on pipes of various diameters and thicknesses, making the machine a versatile tool for metal processing.

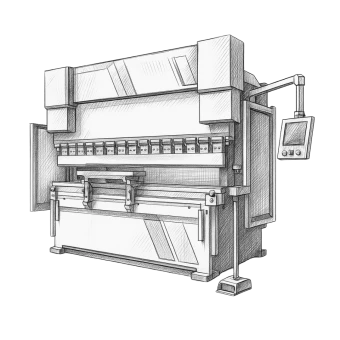

Technical specifications of the Prinzing FME 4-1200:

Pipe diameter: from 80 to 1200 mm

Pipe length: from 250 to 1000 mm

Sheet thickness (400 N/mm²): 4 mm

Flange height: from 10 to 25 mm

Drive type: motorized upper roller input

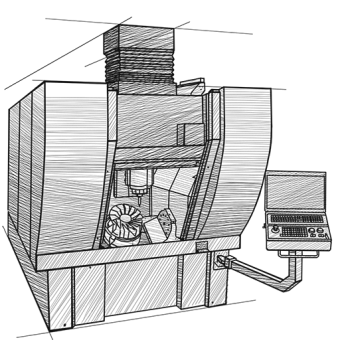

Control: PLC with touchscreen and memory for 200 programs

Lubrication system: automatic lubrication to reduce friction on flanging rollers

Options: automatic diameter adjustment for pipe holding devices, extended bed for pipes up to 6000 mm, central lubrication for machine body

Advantages and features of the Prinzing FME 4-1200:

Accuracy and stability: Programming up to 200 different applications allows for easy machine adjustment to perform various tasks, ensuring precision in every process.

Process automation: The automatic lubrication system and pneumatic counter- and downward holders ensure smooth operation and reduce the need for manual maintenance.

Wide adjustment options: The extended bed and automatic pipe diameter adjustment allow for working with pipes of different sizes, providing flexibility in production processes.

Reliability: Due to high-quality materials and reliable mechanisms, the Prinzing FME 4-1200 flanging machine is durable and an ideal solution for large-scale production capacities.

You can buy the Prinzing FME 4-1200 flanging machine from the KVERB company. We offer:

Delivery across Ukraine

Official warranty and technical support

Professional consultation to help you select the equipment that suits your needs

Contact our managers now to get the best offer for the Prinzing FME 4-1200 flanging machine.

In addition to flanging machines, we also offer sheet metal cutting machines and other machines for the production of ventilation systems, construction profiles, and other specialized products.

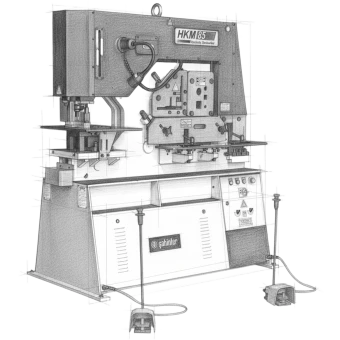

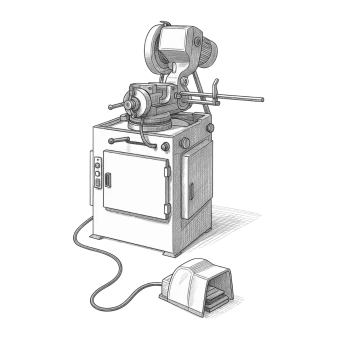

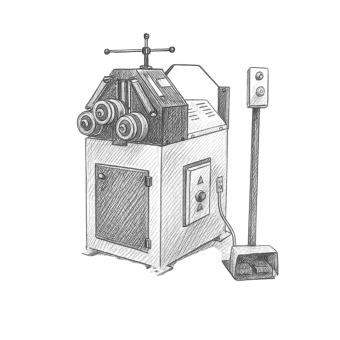

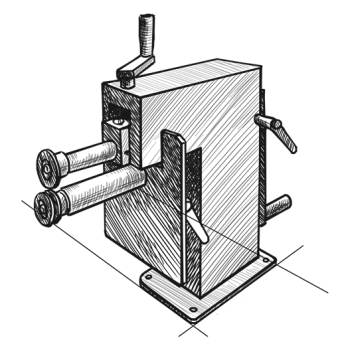

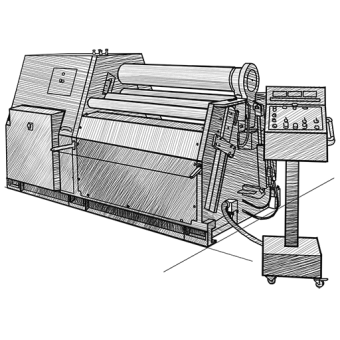

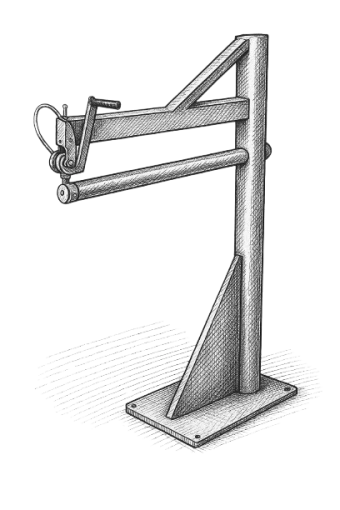

Our company specializes in the sale and service of metalworking equipment, including flanging machines, circular shears, tube benders, roll machines, guillotines, notching machines, and other industrial machines. We cooperate with trusted manufacturers and provide full technical support, ensuring a high level of service throughout all stages of cooperation.

We also offer repair and maintenance services for machines and metal-cutting equipment. Our specialists guarantee the durability and smooth operation of the equipment.

Prinzing FME 4-1200 is used in the metallurgical, oil, gas, and chemical industries, providing high-quality flange manufacturing at all stages of production.

This flanging machine is ideal for companies involved in pipeline production, metal structure processing, and manufacturing pipe connections and flanges for industrial systems. Its capabilities allow for flange production on pipes of various diameters and thicknesses, making the machine a versatile tool for metal processing.

Technical specifications of the Prinzing FME 4-1200:

Pipe diameter: from 80 to 1200 mm

Pipe length: from 250 to 1000 mm

Sheet thickness (400 N/mm²): 4 mm

Flange height: from 10 to 25 mm

Drive type: motorized upper roller input

Control: PLC with touchscreen and memory for 200 programs

Lubrication system: automatic lubrication to reduce friction on flanging rollers

Options: automatic diameter adjustment for pipe holding devices, extended bed for pipes up to 6000 mm, central lubrication for machine body

Advantages and features of the Prinzing FME 4-1200:

Accuracy and stability: Programming up to 200 different applications allows for easy machine adjustment to perform various tasks, ensuring precision in every process.

Process automation: The automatic lubrication system and pneumatic counter- and downward holders ensure smooth operation and reduce the need for manual maintenance.

Wide adjustment options: The extended bed and automatic pipe diameter adjustment allow for working with pipes of different sizes, providing flexibility in production processes.

Reliability: Due to high-quality materials and reliable mechanisms, the Prinzing FME 4-1200 flanging machine is durable and an ideal solution for large-scale production capacities.

You can buy the Prinzing FME 4-1200 flanging machine from the KVERB company. We offer:

Delivery across Ukraine

Official warranty and technical support

Professional consultation to help you select the equipment that suits your needs

Contact our managers now to get the best offer for the Prinzing FME 4-1200 flanging machine.

In addition to flanging machines, we also offer sheet metal cutting machines and other machines for the production of ventilation systems, construction profiles, and other specialized products.

Our company specializes in the sale and service of metalworking equipment, including flanging machines, circular shears, tube benders, roll machines, guillotines, notching machines, and other industrial machines. We cooperate with trusted manufacturers and provide full technical support, ensuring a high level of service throughout all stages of cooperation.

We also offer repair and maintenance services for machines and metal-cutting equipment. Our specialists guarantee the durability and smooth operation of the equipment.

Specifications Flanging Machine Prinzing FME 4-1200

- Tube length min/max mm 250 - 1000 mm

- Tube diameter min/max mm 80/1200 mm

- Metal processing thickness (400 N/mm²) mm 4 mm

- Flange height min/max mm 10/25 mm

Reviews

There are no reviews on this product yet, be the first

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21