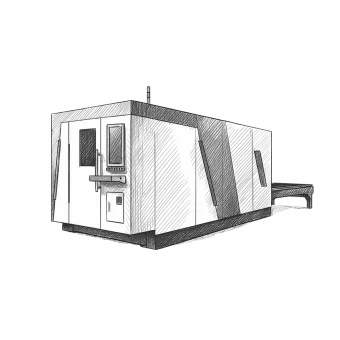

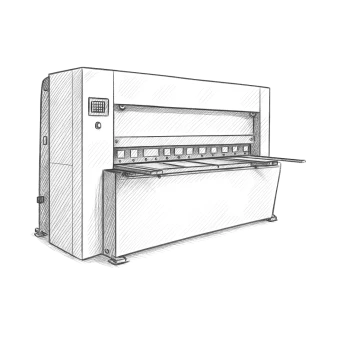

ELECTROMECHANICAL GUILLOTINES

Filters

Filters

PRODUCTS YOU HAVE VIEWED

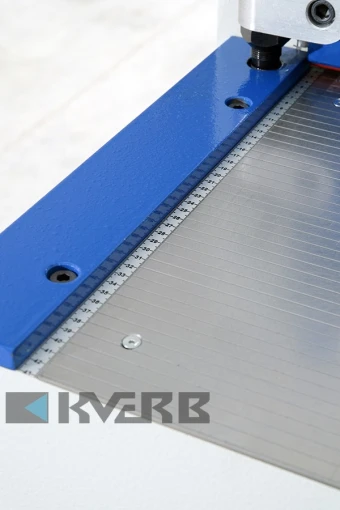

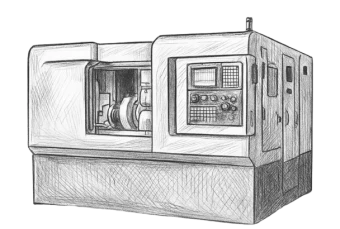

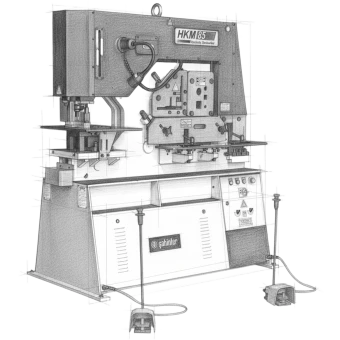

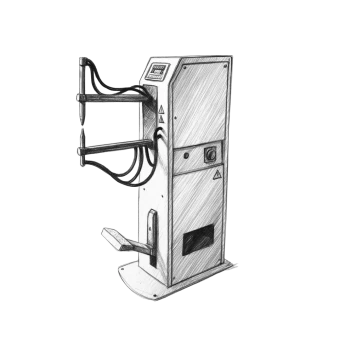

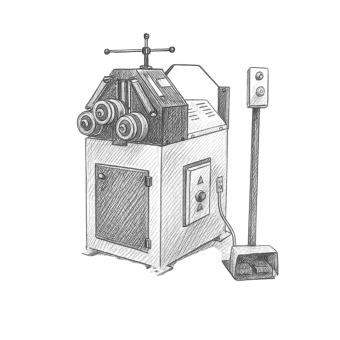

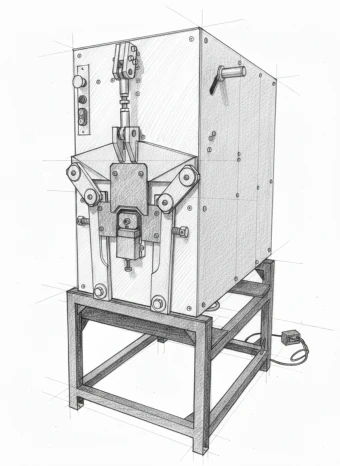

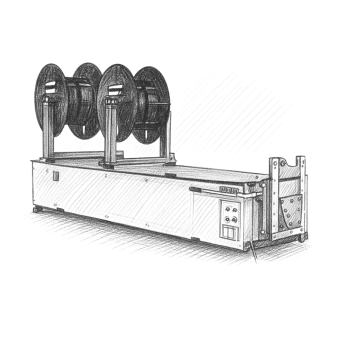

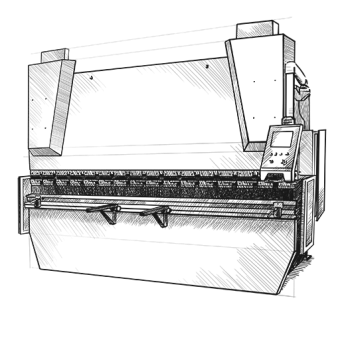

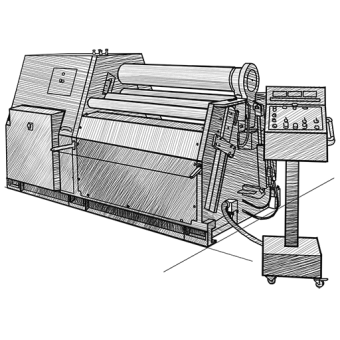

Electromechanical guillotine — is professional equipment for precise and clean cutting of sheet metal. It combines the advantages of mechanical shears and automation. The core of its operation is an electric motor that drives the cutting mechanism through a gear system, and the blade descends with high precision, ensuring a straight cut along the entire length of the workpiece.

Advantages and areas of application

Electromechanical guillotine shears have a number of key advantages:

- High productivity and consistent cutting quality.

- Ease of use and maintenance.

- Capability to process sheets up to 6 mm thick and up to 4 meters long.

- Clean cut without thermal impact or deformation.

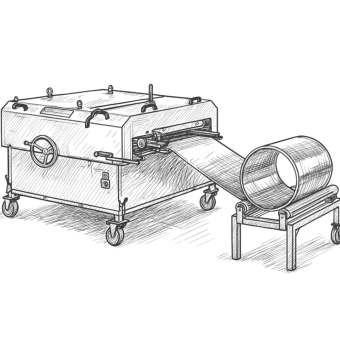

Electromechanical guillotines are widely used in manufacturing facilities:

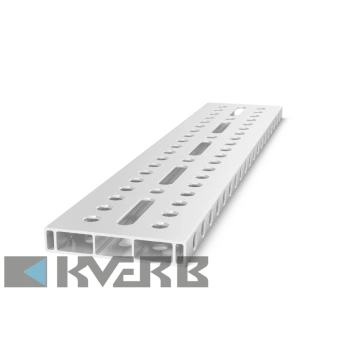

- In workshops for the production of ventilation and cladding.

- In metalworking and assembly shops.

- In companies engaged in the production of facades and industrial housings.

How to choose an electromechanical guillotine

When choosing an electromechanical guillotine, it is important to consider several parameters:

- The thickness and type of metal you plan to cut.

- The length of the cut and how frequently the machine will be used.

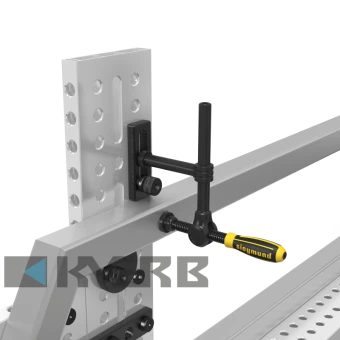

- Availability of a hold-down beam and back gauge.

- Ease of control and ergonomics.

Availability of spare parts and service.

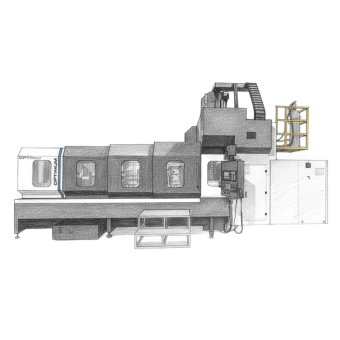

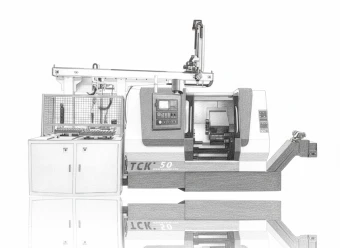

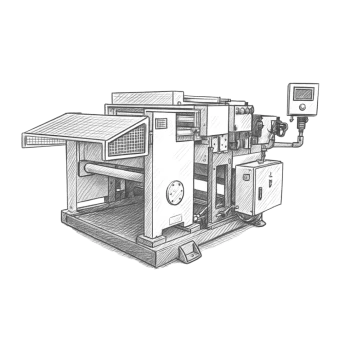

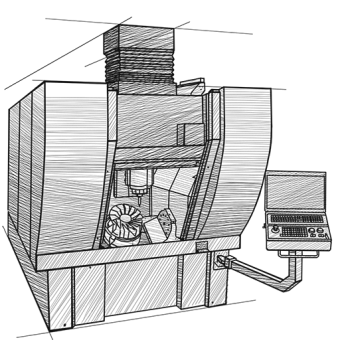

For light-duty tasks, MAAD NGM models with cutting lengths from 700 to 2000 mm are suitable. For intensive work in continuous production conditions, SAY-MAK models of the SRGM-FR, SRGM-HFR, SRGM-CL series are optimal — with lengths up to 4200 mm and cutting capacity up to 6 mm.

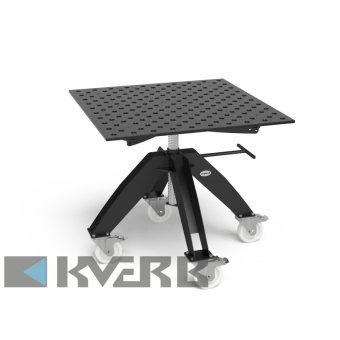

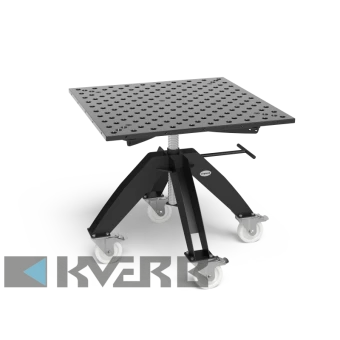

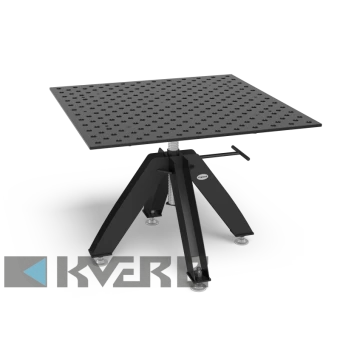

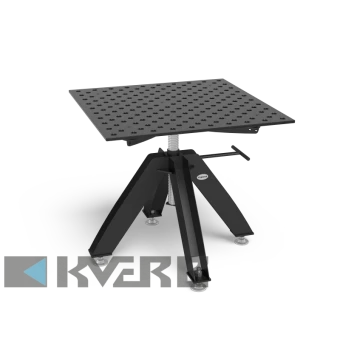

KVERB assortment — proven models from leading manufacturers:

MAAD (Poland) — NGM series with cutting lengths from 700 to 3000 mm and cutting thickness up to 2 mm.

SAY-MAK (Turkey) — a wide range of SRGM models from 1100 to 4200 mm, including heavy-duty high-power versions.

ERBEND — semi-automatic EMS machines for serial and precise production.

All models are certified.

Where to buy an electromechanical guillotine

KVERB offers electromechanical guillotines with warranty and delivery throughout Ukraine — we work only with official manufacturers and provide service support — available equipment for any complexity of tasks.

Our advantages:

- wide selection of models;

- technical support and warranty;

- personnel training;

- customized solution selection;

- wholesale and retail supply.

Contact KVERB and get reliable professional equipment that will ensure stable and high-quality performance for your production.

+38 (098) 127 45 85

+38 (098) 127 45 85

+38 (050) 673 51 21

+38 (050) 673 51 21